Filtering apparatus and method for mixing, extraction and/or separation

A filter and filter equipment technology, applied in the direction of separation methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problem that the insert cannot be moved in the external box and cannot be taken out, so as to achieve a cheap brewing process and avoid cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0224] Example 1: Method of making beer using the apparatus of the present invention

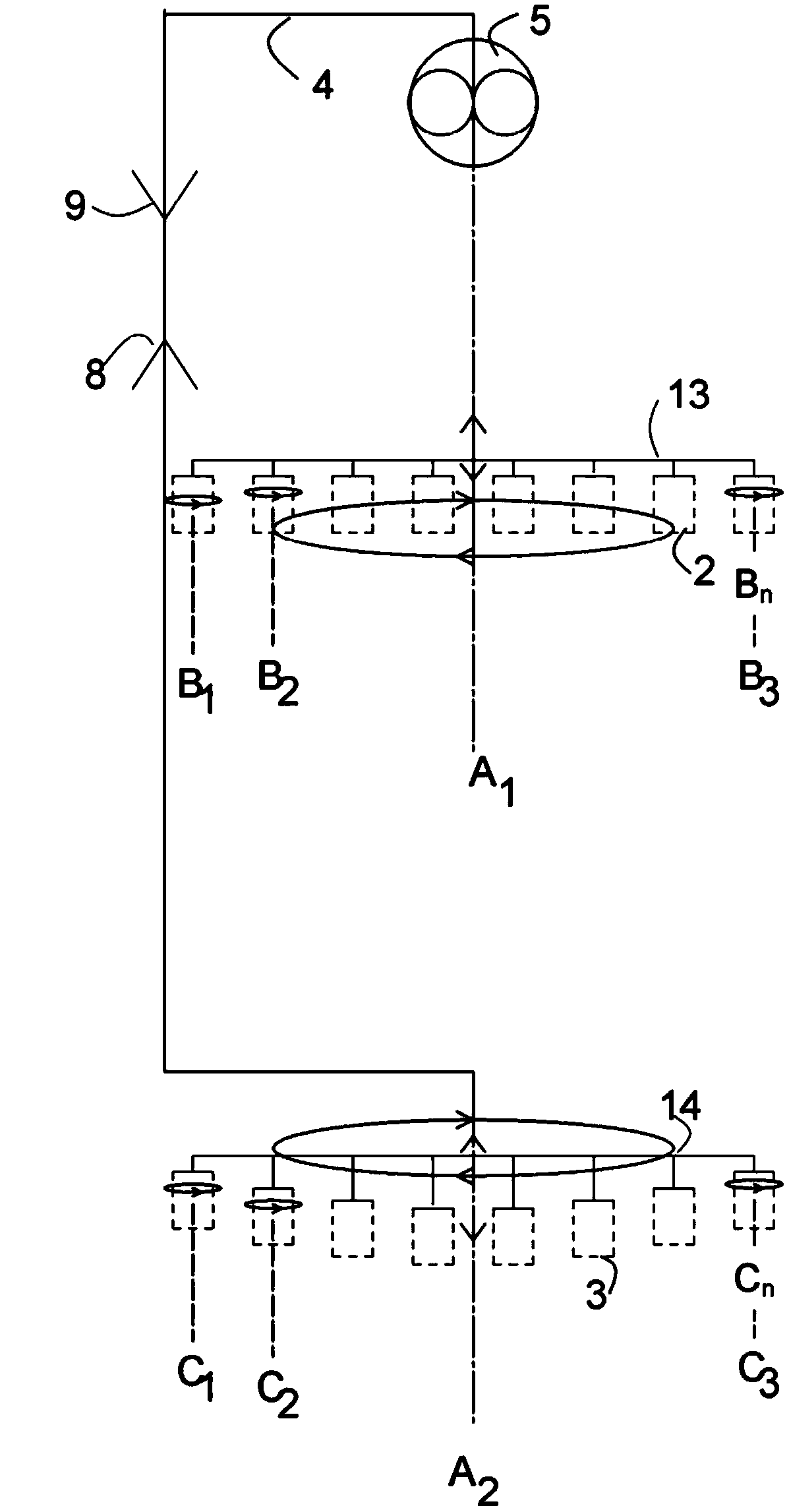

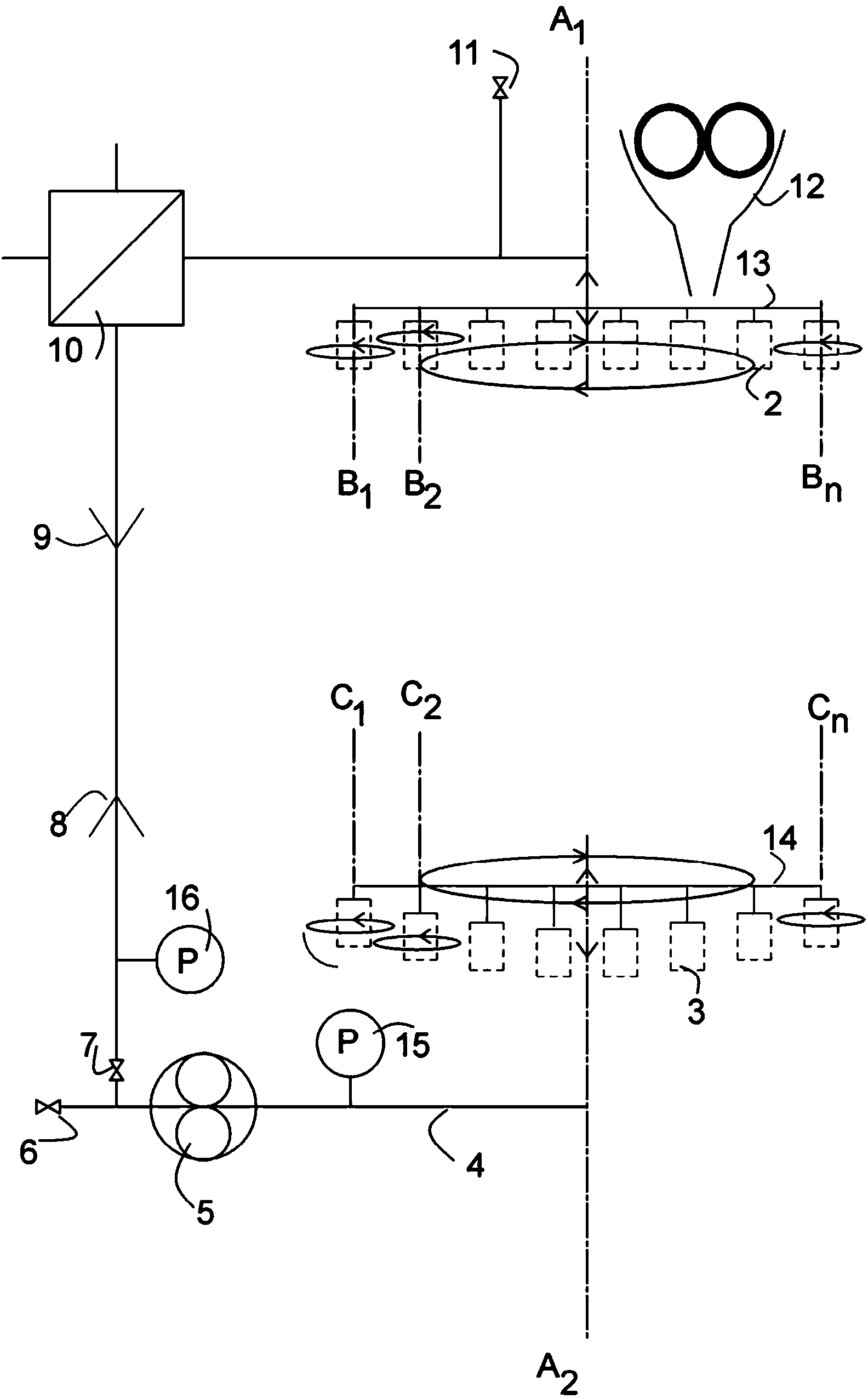

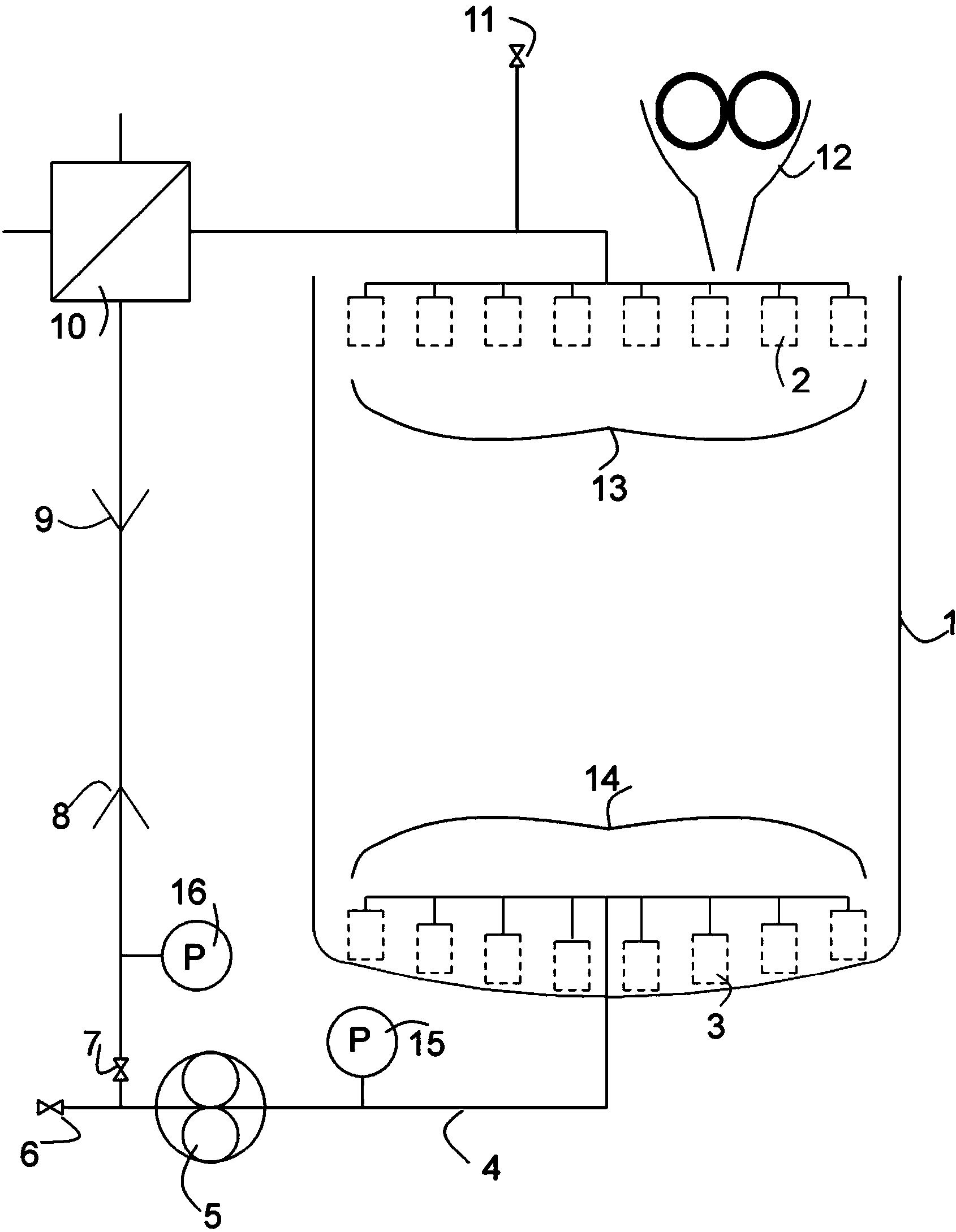

[0225] 1. Mounting the device of the invention on the vessel.

[0226] 2. Add 200 liters of cold tap water to the container through the supply valve for fluid (11).

[0227] 3. Operate the circuit part (5) to allow flow in the flow direction (8), ie from the bottom to the top of the vessel.

[0228] 4. The temperature regulating device (10) is operated at a temperature of 80°C so that the temperature of the fluid exiting the temperature regulating device is about 54°C.

[0229] 5. Interrupt the operation of the device for regulating the temperature.

[0230] 6. 40 kg of solid phase such as comminuted, rolled or milled malt or barley are added to the vessel through the solid material addition device (12). *

[0231] 7. Adjust the pH to approximately 5.8. *

[0232] 8. Regulate the temperature of the fluid phase by operating the temperature regulating means (10) at a temperature of 55°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com