Automatic assembling tool for impeller box and centre of water meter movement

An automatic assembly and top-notch technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low degree of automation, poor assembly quality and uniformity, difficult to control the pressure, etc., to achieve reliable and uniform quality, improve The effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0056] Such as Figure 12 , Figure 13 and Figure 14 As shown, the leaf hinge 10 in the prior art is composed of three parts, namely the port part 1a, the lower end part 1c and the convex ring part 1b between the port part 1a and the lower end part 1c, wherein the diameter of the port part 1a is larger than The lower end 1c has a diameter, and the inner wall of the lower end 1c has a shaft hole 1d for setting the tip 10a. One end of the tip 10a forms a tip, and the other end is fitted in the shaft hole 1d of the leaf hinge.

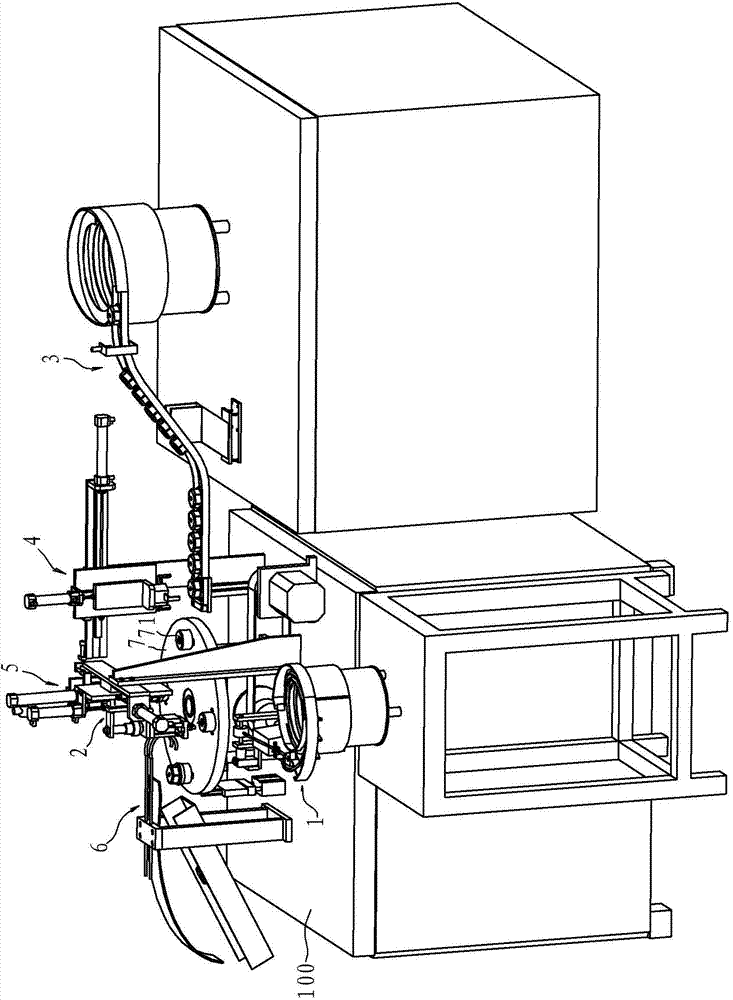

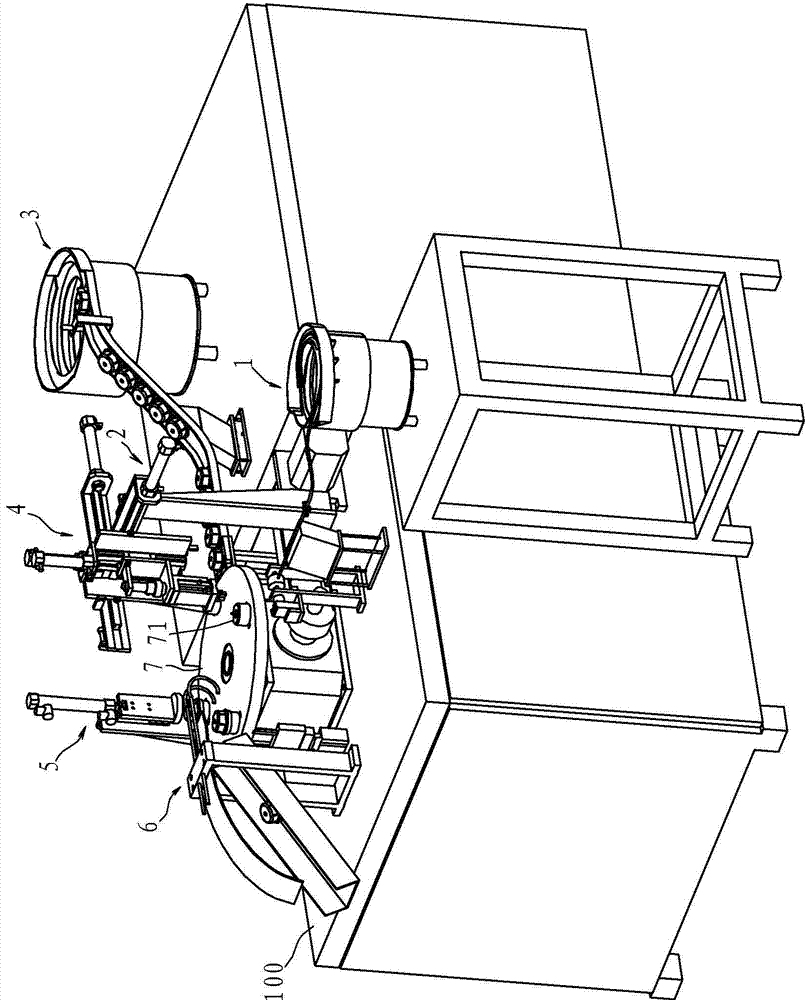

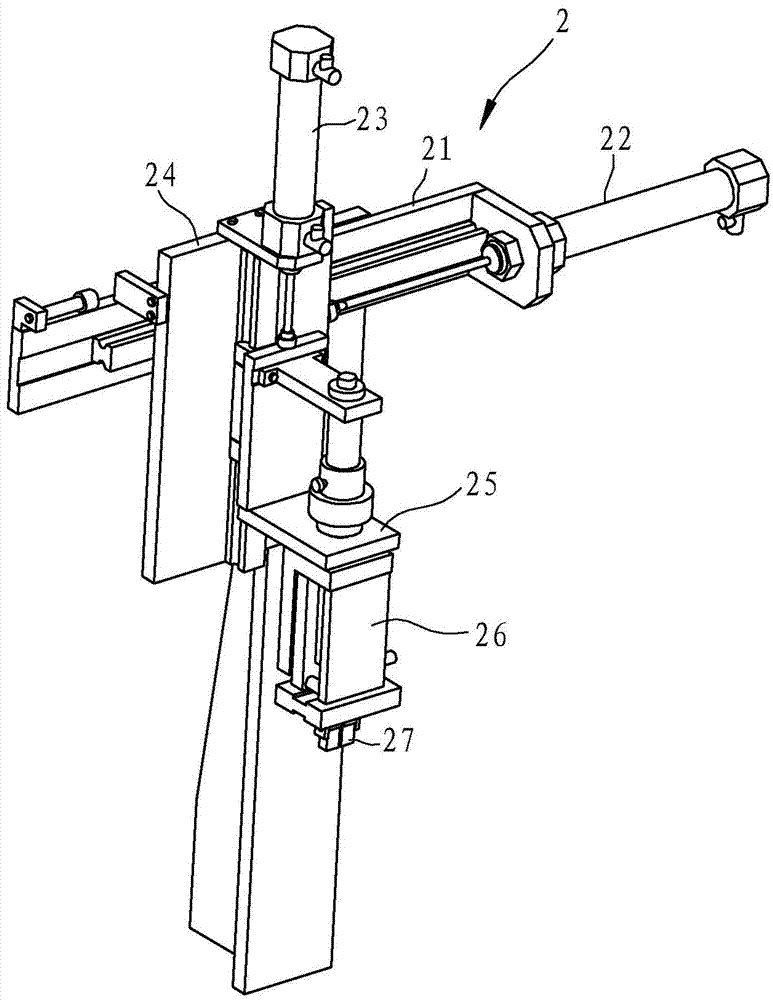

[0057] Such as figure 1 and figure 2 As shown, the water meter core leaf and top automatic assembly tooling in this embodiment includes a rotating disk 7, a top vibration output mechanism 1, a top clamping mechanism 2, a leaf hinge vibration output mechanism 3, a leaf hinge clamping mechanism 4, and a rotating disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com