Forced-rinsing cooling mechanism of multi-sheet combined stone sawing machine

A multi-piece combination and cooling mechanism technology, applied in stone processing equipment, manufacturing tools, work accessories, etc., can solve the problems of insufficient cooling circular saws, low quality of stone slabs, and high use costs, and achieve easy cutting and slicing. Good quality and long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

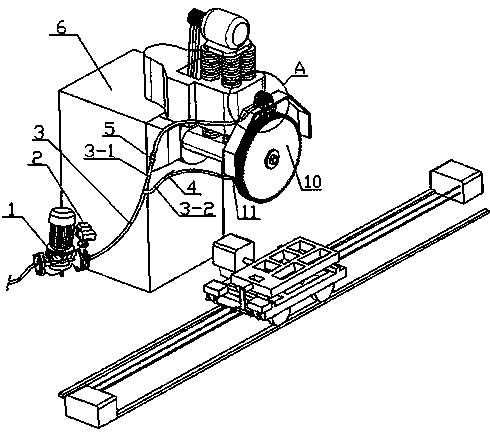

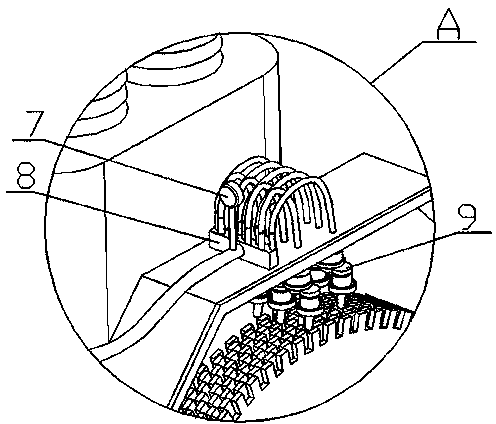

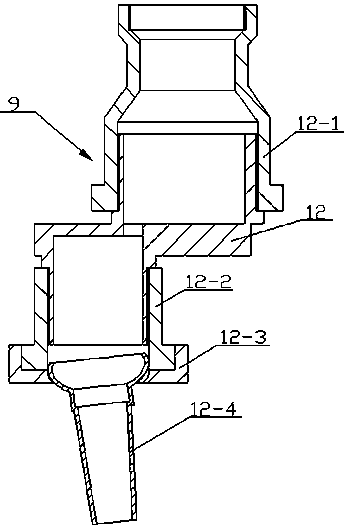

[0014] see figure 1 , figure 2 , image 3 , the forced flushing and cooling mechanism of the stone multi-piece combined sawing machine of the present invention includes the stone multi-piece combined sawing machine. The electric on-off valve 2 connected with the pressure pump, the electric on-off valve 2 is connected with the water pressure gauge 7 and the diversion water tank 8 through the high-pressure branch pipe Ⅰ3-1, and the electric on-off valve 2 is connected with the horizontal water spray pipe through the high-pressure branch pipe II. Ball valves 5 and 4 are installed on the high-pressure branch pipe I3-1 and high-pressure pipe branch pipe II3-2 between the horizontal water spray pipe and the water pressure gauge, and a joint is provided on the diversion water tank 8, which is connected to one end of the high-pressure pipe, and the high-pressure The other end of the pipe is connected with the adjustable shower head 9 through the joint on the waterproof cover.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com