Small synchronous belt kitchen garbage oil-water separator

A technology of oil-water separator and kitchen waste, applied in the direction of liquid separation, separation method, mechanical oscillation water/sewage treatment, etc., can solve problems such as inability to work, difficult to separate dissolved oil and emulsified oil, coalescing material or membrane clogging , to achieve the effect of convenient movement, improved oil-water separation effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

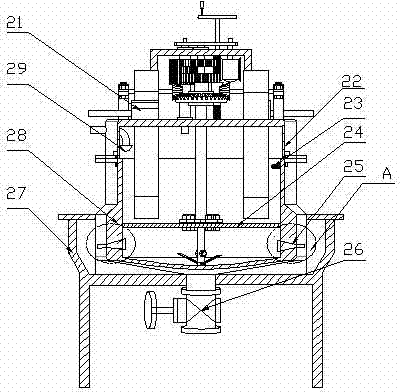

[0028] see Figure 1 to Figure 4 , the present invention comprises frame 27, upper case cover 22, lower case body 28, the inlet pipe 29 that is arranged on the upper end of upper case cover 22 and the drain valve 26 at the bottom of lower case body 28, driving mechanism, transmission mechanism, belt type picks up oil device, waste residue cleaning device and ultrasonic coarse granulation device;

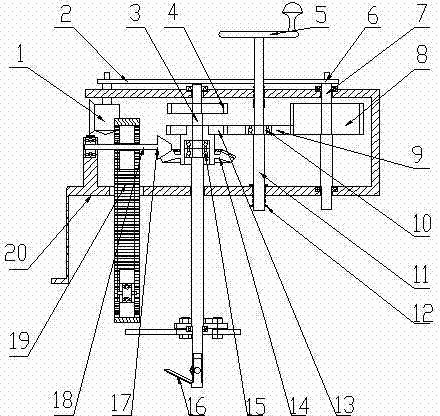

[0029] The belt-type oil pick-up device includes a large spur gear 13, a large bevel gear 14, a parallel bearing 15, a central transmission shaft 3, two small bevel gears 17 symmetrically distributed with the central transmission shaft 3, a small bevel gear shaft 18 and an oil pick-up Belt 19, and the oil scraping groove 21 that is connected with upper box cover 22, is provided with oil outlet on the oil scraping groove 21, and the notch of oil scraping groove 21 is upwards, contacts with oil pick-up belt 19, and big spur gear 13 and The large bevel gear 14 is connected with the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com