Acid soil conditioner and preparation technology thereof

A technology of acidic soil and preparation process, applied in the direction of soil conditioning materials, other chemical processes, organic fertilizers, etc., can solve the problems of unreasonable use and discarding, achieve the effect of suitable crop growth and solve soil acidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The acidic soil conditioner of this embodiment includes the following raw materials: plant ash, oyster powder, medical stone powder, the weight ratio of the above three is: 5:4:1; wherein the plant ash is the ashes obtained after burning apple wood.

[0026] Acidic soil conditioner comprises the following preparation processes:

[0027] 1. High temperature calcination

[0028] Calcining oyster shells at 700°C;

[0029] 2. Crushing

[0030] The medical stone and the oyster shell calcined at high temperature are respectively sent to the pulverizer for pulverization, and pulverized to 60 mesh;

[0031] 3. Mix

[0032] Mix plant ash with crushed material.

[0033] Method of use: Sprinkle the acidic soil conditioner of this embodiment on the soil, and then sprinkle once every 2-3 months, and sprinkle 3-4 times to make the pH of the soil reach 6-7.

Embodiment 2

[0035] The acidic soil conditioner of this embodiment includes the following raw materials: plant ash, scallop shell powder, medical stone powder, the weight ratio of the above three is: 1: 1: 1;

[0036] The plant ash of the present embodiment is the ashes obtained after burning apple wood.

[0037] The preparation technology of the acidic soil conditioner of the present embodiment comprises following preparation technology:

[0038] 1. High temperature calcination

[0039] Calcining the scallop shell at a high temperature of 1000°C;

[0040] 2. Crushing

[0041] The medical stone and the scallop shell calcined at high temperature are respectively sent to the pulverizer for pulverization, and pulverized to 80 mesh;

[0042] 3. Mix

[0043] Mix plant ash with crushed material.

Embodiment 3

[0045] The acidic soil conditioner of this embodiment comprises the following raw materials: plant ash, clam shell powder, medical stone powder, the weight ratio of the above three is: 80:60:30;

[0046] The plant ash of the present embodiment is the ashes obtained after burning apple wood.

[0047] The preparation technology of the acidic soil conditioner of the present embodiment comprises following preparation technology:

[0048] 1. High temperature calcination

[0049] The clam shell is calcined at 800°C;

[0050] 2. Crushing

[0051] The medical stone and the clam shell calcined at high temperature are respectively sent to the pulverizer for pulverization, and pulverized to 50 mesh;

[0052] 3. Mix

[0053] Mix plant ash with crushed material.

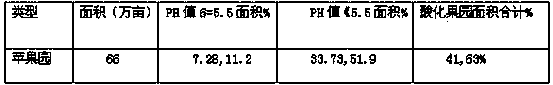

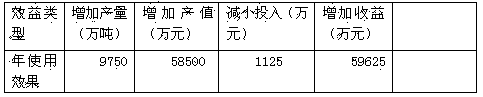

[0054] The acidic soil conditioner of above-mentioned embodiment has following beneficial effect:

[0055] 1. Economic benefits

[0056] After the acidic soil conditioner of the present invention is successfully developed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com