Fluoride solidifying agent for treating fluorine pollution caused by burning coal and preparation method and application method thereof

A pollution control and fluorine-fixing agent technology, applied in the field of environmental pollution prevention and control, can solve problems such as corrosion of boilers and flue gas purification equipment, ecological environment damage, residues in ash, etc., achieve high-efficiency solidification, low production cost, and reduce fluorine content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] One, the preparation of fluorine-fixing agent of the present invention

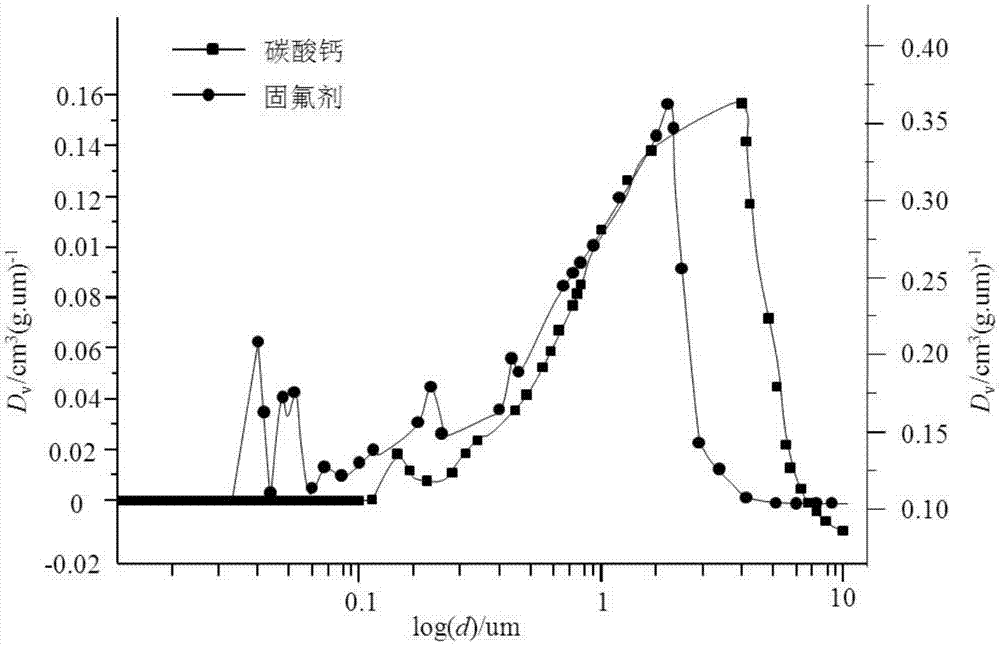

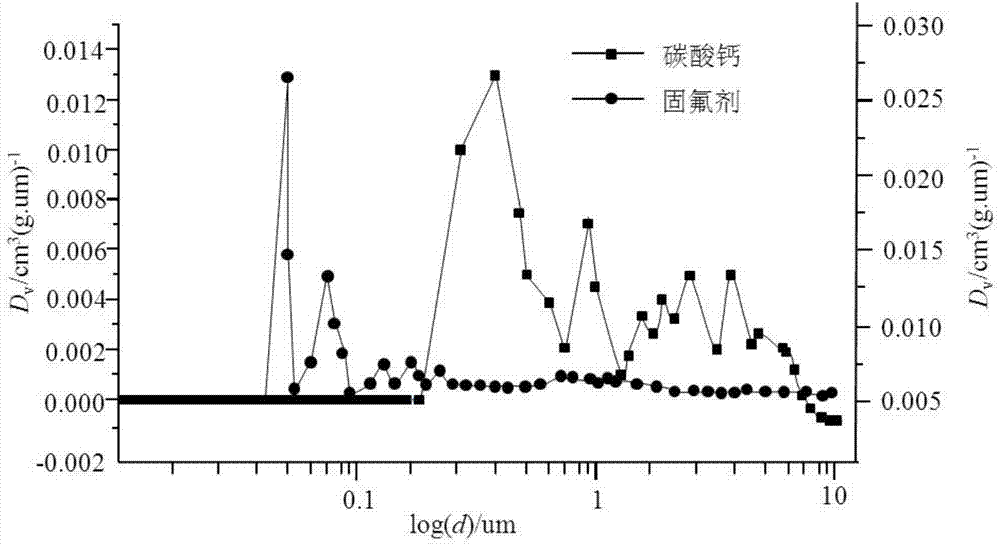

[0023] 1. The effect of grinding particle size, modulator type and molar ratio of modulated ions on the effect of coal-fired fluorine fixation

[0024] In the process of high-temperature coal combustion, calcium ions are the active sites for adsorption and chemical fixation of fluorine, and the fixation of fluorine is achieved through the capture of fluorine by calcium matrix materials. In order to further improve the efficiency of immobilizing fluorine, physical and chemical methods can be used to improve the porosity and specific surface area of calcium matrix materials and improve the activity of calcium ions from the perspective of additive modification. In order to increase the contact area between the calcium matrix material and the coal, it can be grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com