Sprayed wool yarn producing method

A production method, the technology of spraying wool yarn, which is applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of easy pilling, single color, and unable to meet people's aesthetic needs, and achieve the effect of improving pilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022](1) The raw materials of the roving are 3D*65mm acrylic fiber, 2D*65mm acrylic fiber and 60s Australian wool with a fiber length of 80mm, wherein the weight ratio of 3D*65mm acrylic fiber to 2D*65mm acrylic fiber is 2:1, The weight ratio of acrylic fiber and Australian wool is 94%: 6%; 40D nylon filament is selected as the material for weaving mesh bags; acrylic fiber is a material with low cost but good touch, bright and bright appearance, recovery performance, and not easy to deform , the roving used as a raw material for the production of wool-jet yarn can bring good hand feel and resilience while reducing costs, especially when two different specifications of acrylic fibers are used in combination, the hand feel and compactness can be further improved; Australian wool as a kind of wool It can provide high-quality soft comfort and elegant gloss, and it can be combined with good-touch, bright and bright acrylic fibers to make the yarn elegant in appearance and feel at t...

Embodiment 2

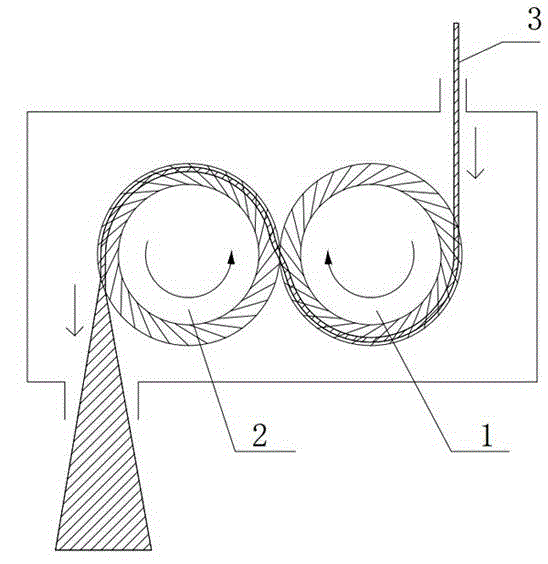

[0029] Keeping the other conditions of Example 1 constant, the two opening rollers with a diameter of 80 to 85mm that can be rotated in opposite directions on the hair spraying machine used in the step (4), and that the diameter of the external tangent and horizontal cooperation is set are 50mm. Comb rollers instead.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com