A method of manufacturing a large cylindrical storage tank

A manufacturing method and cylindrical technology, applied in the direction of large-capacity bulk material storage, building type, construction, etc., can solve the problems of high cost, increased manufacturing cost, low efficiency, etc. The effect of improving the quality of the tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] like Figure 1~6 Among them, a manufacturing method of a large cylindrical storage tank comprises the following steps:

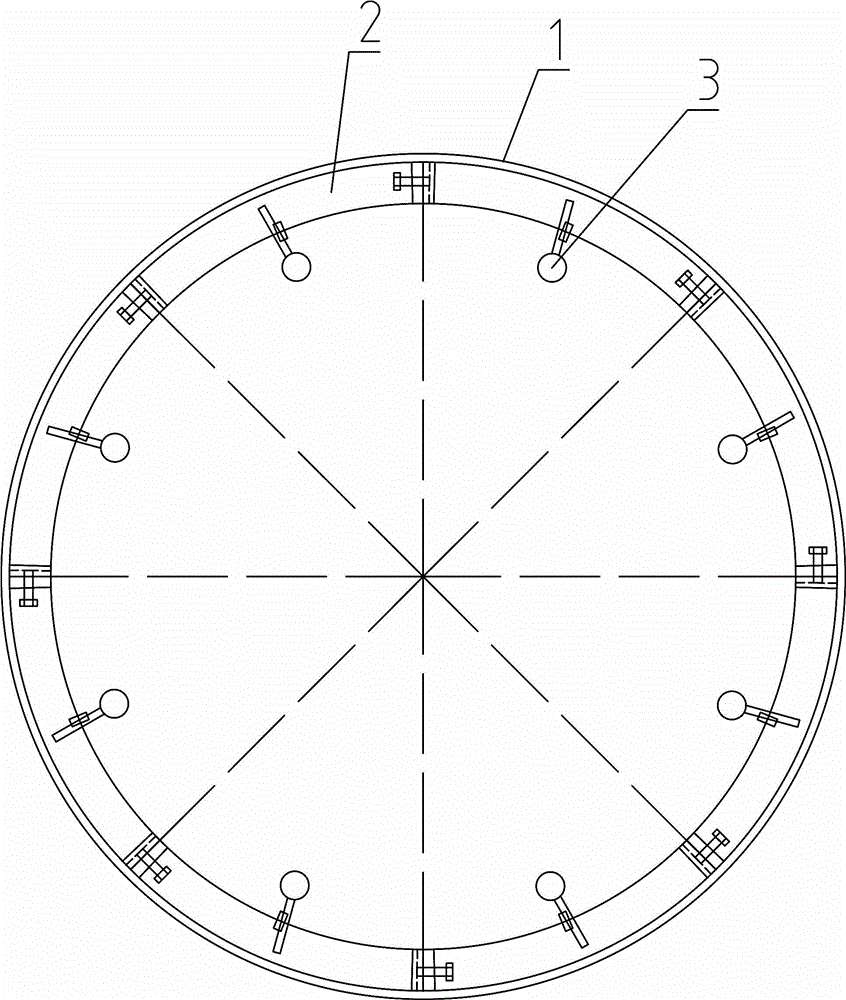

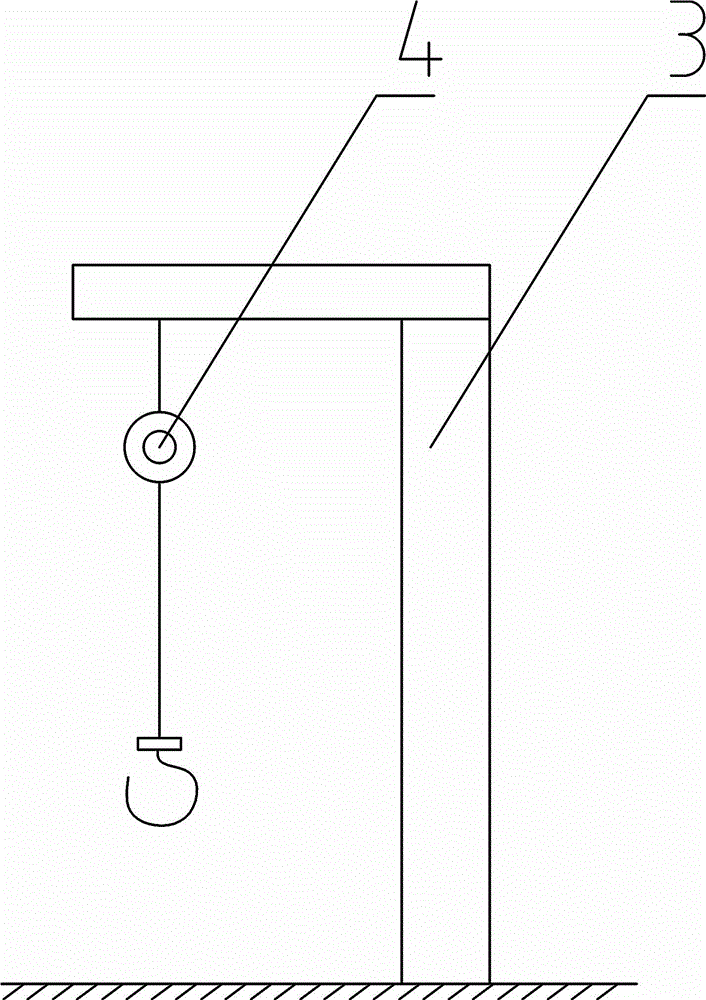

[0030] 1. On the tank body installation platform 5 in the tank body 1, a plurality of lifting columns 3 are evenly distributed along the circumference, and an electric hoist 4 is arranged on the lifting column 3, and the height of the lifting column 3 is higher than a layer of tank body components;

[0031] 2. The first layer of tank body components is assembled by welding and assembling multiple arc-shaped segments.

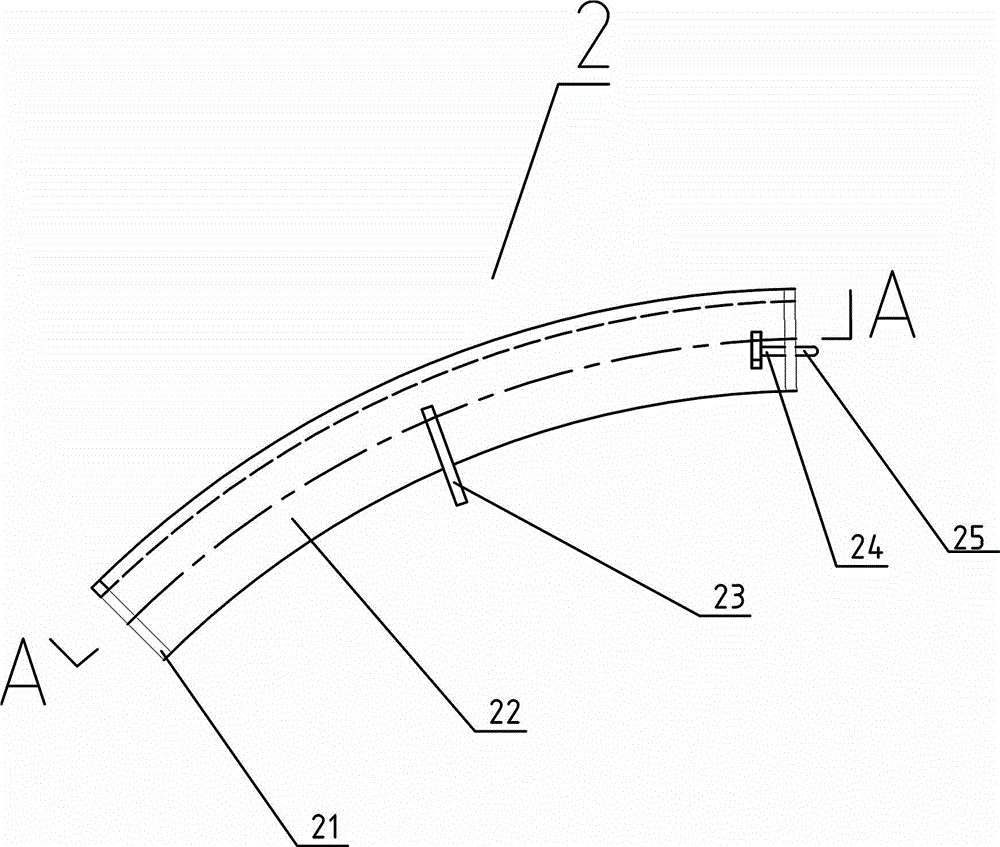

[0032] In a preferred solution, a stiffening ring 7 is welded at the middle of the inner wall or outer wall of each layer of the tank member.

[0033] A hoisting stiffening ring 2 is installed inside the tank member of the first layer near the bottom, and lifting lugs 23 are provided on the hoisting stiffening ring 2 corresponding to the lifting column 3;

[0034] In a preferred solution, an annular assembling platform 6 is also provi...

Embodiment 2

[0047] On the basis of embodiment 1, illustrate further with example:

[0048] 1. Prepare the tank body installation platform 5 of the storage tank first, and pre-embed and install the lifting column 3 and the ring-shaped assembly platform 6 embedded parts for assembly at the corresponding positions of the tank body installation platform 5;

[0049] 2. According to the height of the hollow cylinder of each layer, that is, the tank member, usually the width of the commercially available steel plate shall prevail. Generally, the width of the plate is 1.5 meters or 2 meters. The total weight of the entire storage tank is designed to determine the height of the lifting column. and quantity, take a sand and gravel tank as an example to describe the production and installation method in detail:

[0050] A sand and gravel tank has a diameter of 16m and a height of 18m. The material of the tank body is 8mm steel plate supplemented with a small amount of angle steel to make a stiffenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com