Heavy-draught multi-column floating foundation of offshore wind turbine

A wind turbine, floating technology, applied in the field of deep draft multi-column floating foundation, can solve the problems of poor practicability and high power generation cost, and achieve the effects of restraining movement, reducing construction cost, and reducing the area of the water plane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment, present embodiment is based on the premise of technical solution of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

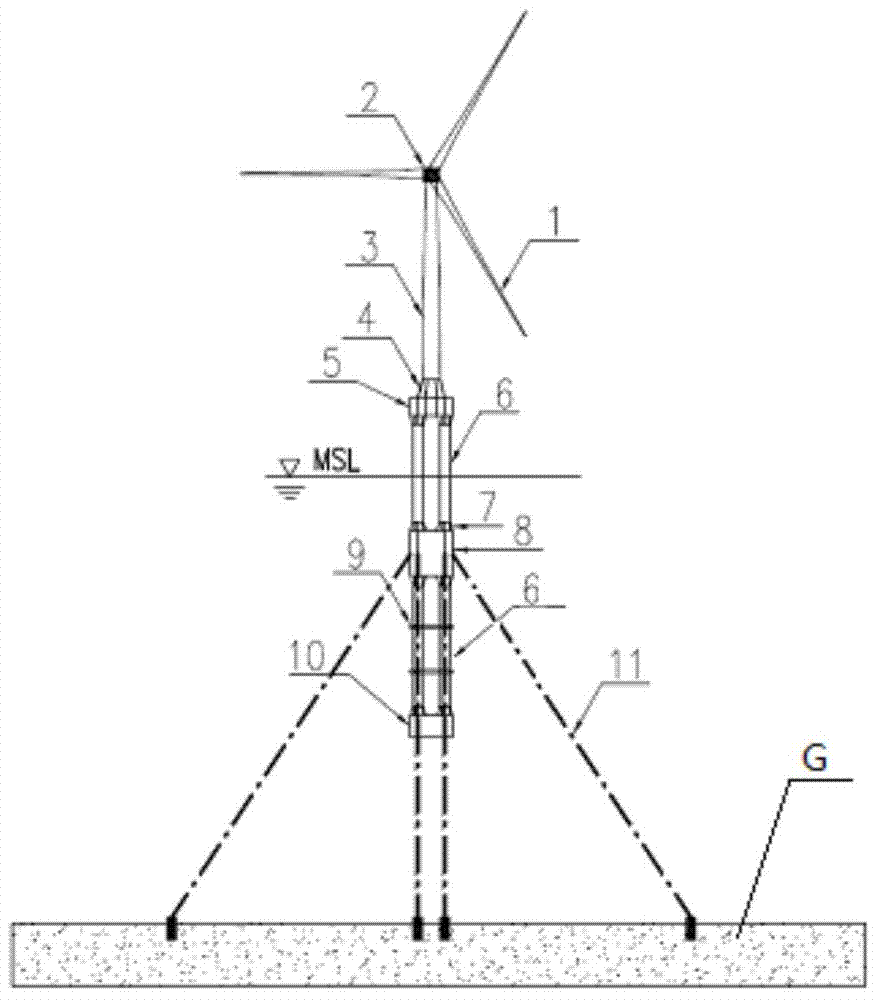

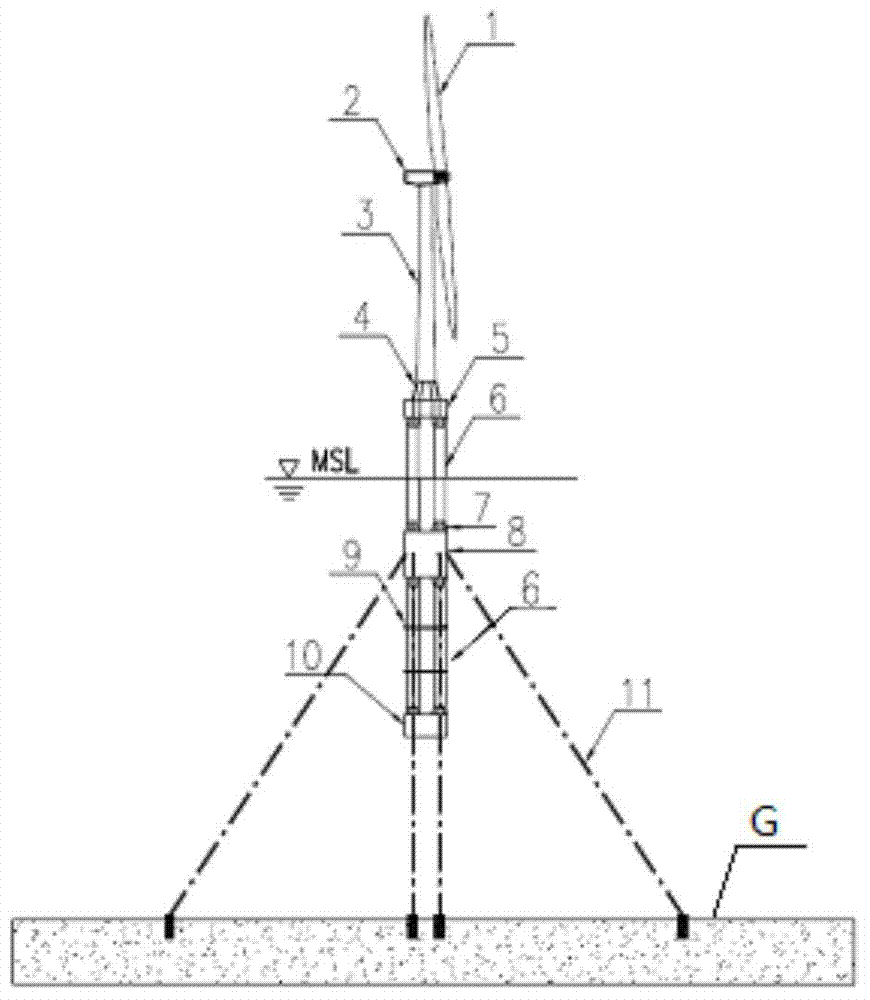

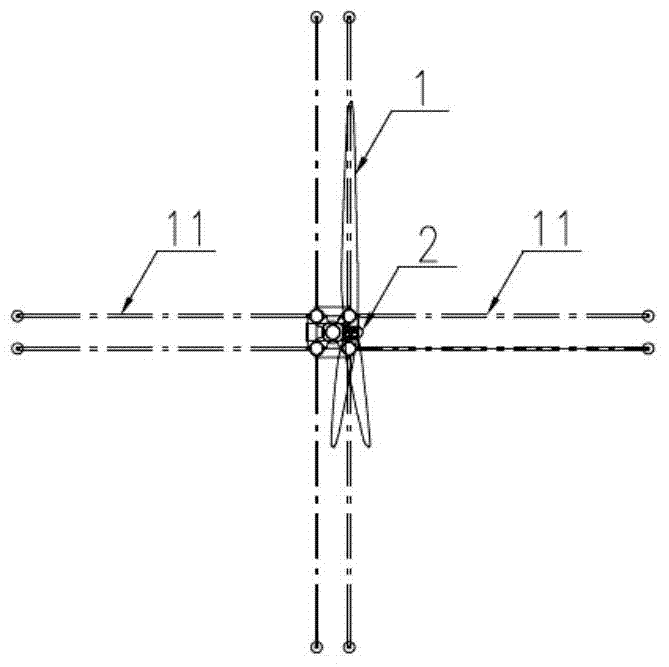

[0025] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the foundation of the deep-draft multi-column offshore floating wind turbine described in this embodiment includes: wind wheel 1, nacelle 2, tower 3, tower transition structure 4, reinforcement structure 5, upper column group, lower Toward column group, circumferential column transition structure 7, hard cabin 8, heave plate structure 9, soft cabin 10 and mooring system 11.

[0026] The connection relationship is:

[0027] The wind rotor 1 is connected to the front of the nacelle 2, the wind rotor 1 and the nacelle 2 are installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com