Plated LED radiator

A heat sink and flat panel technology, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problems of poor heat dissipation uniformity and low utilization rate of heat transfer medium, etc., and achieve Unlimited installation angle, reduced weight, and improved heat dissipation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

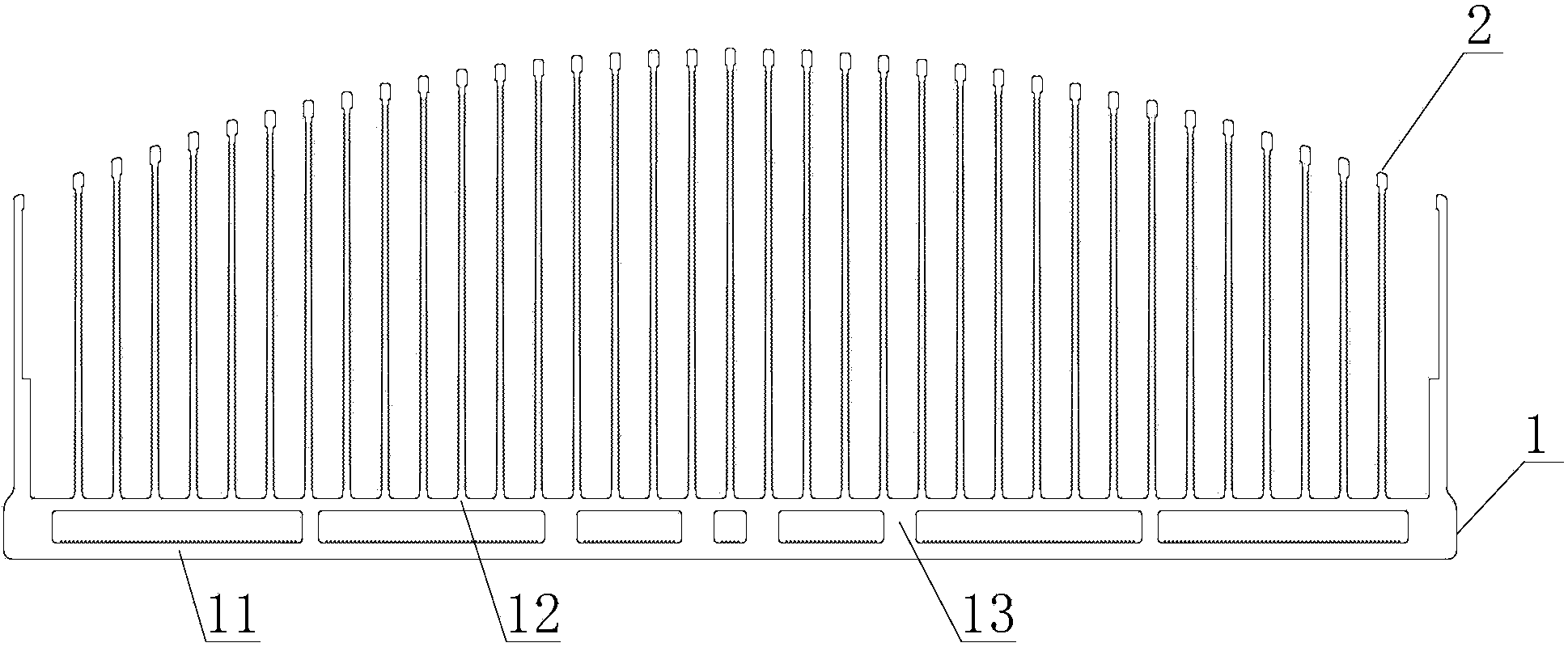

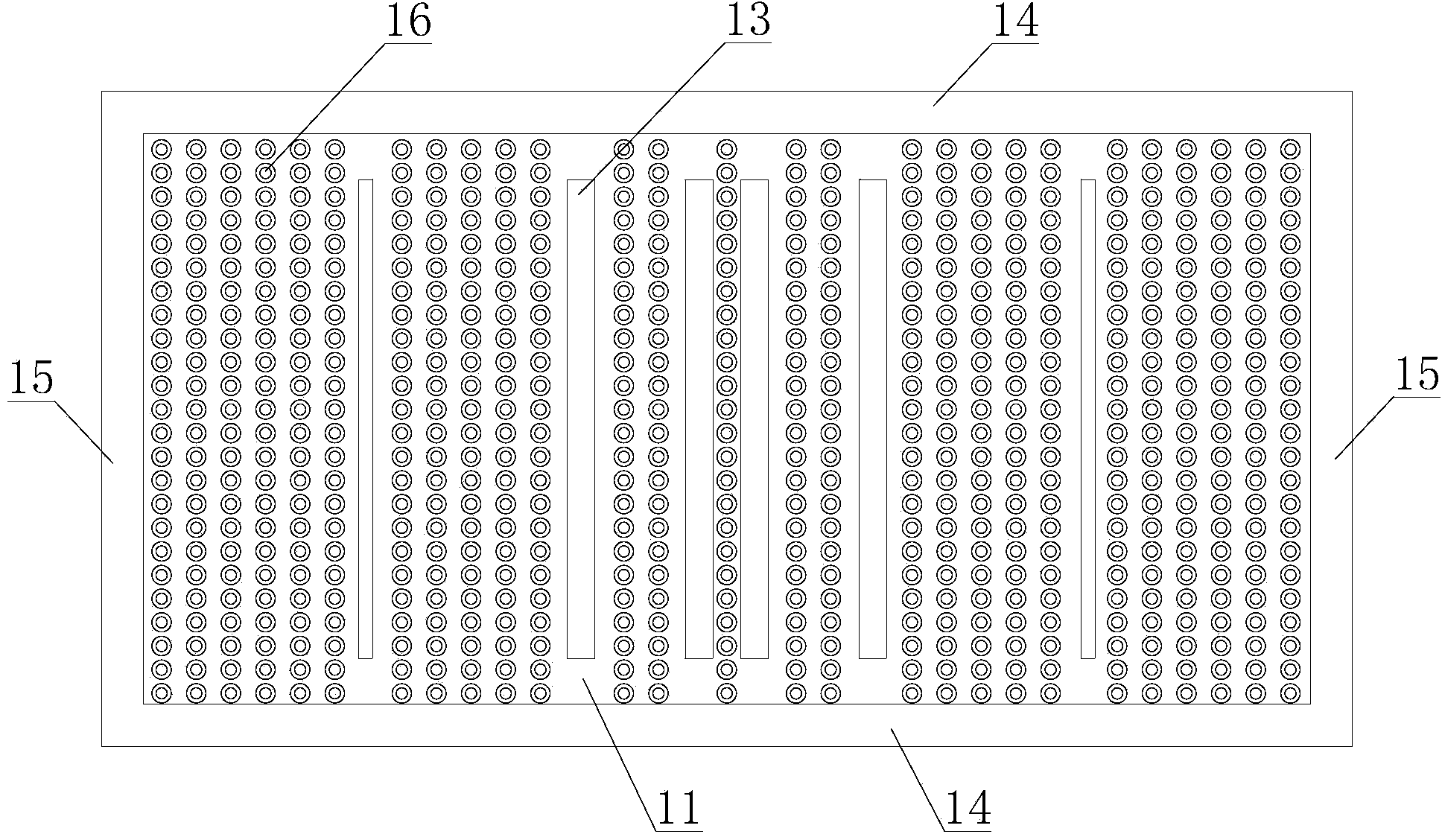

[0018] Such as figure 1 combine figure 2 As shown, an LED flat radiator includes a rectangular heat conduction plate 1 and a plurality of heat dissipation fins 2. The heat conduction plate 1 and the heat dissipation fins 2 are integrally extruded from aluminum alloy profiles.

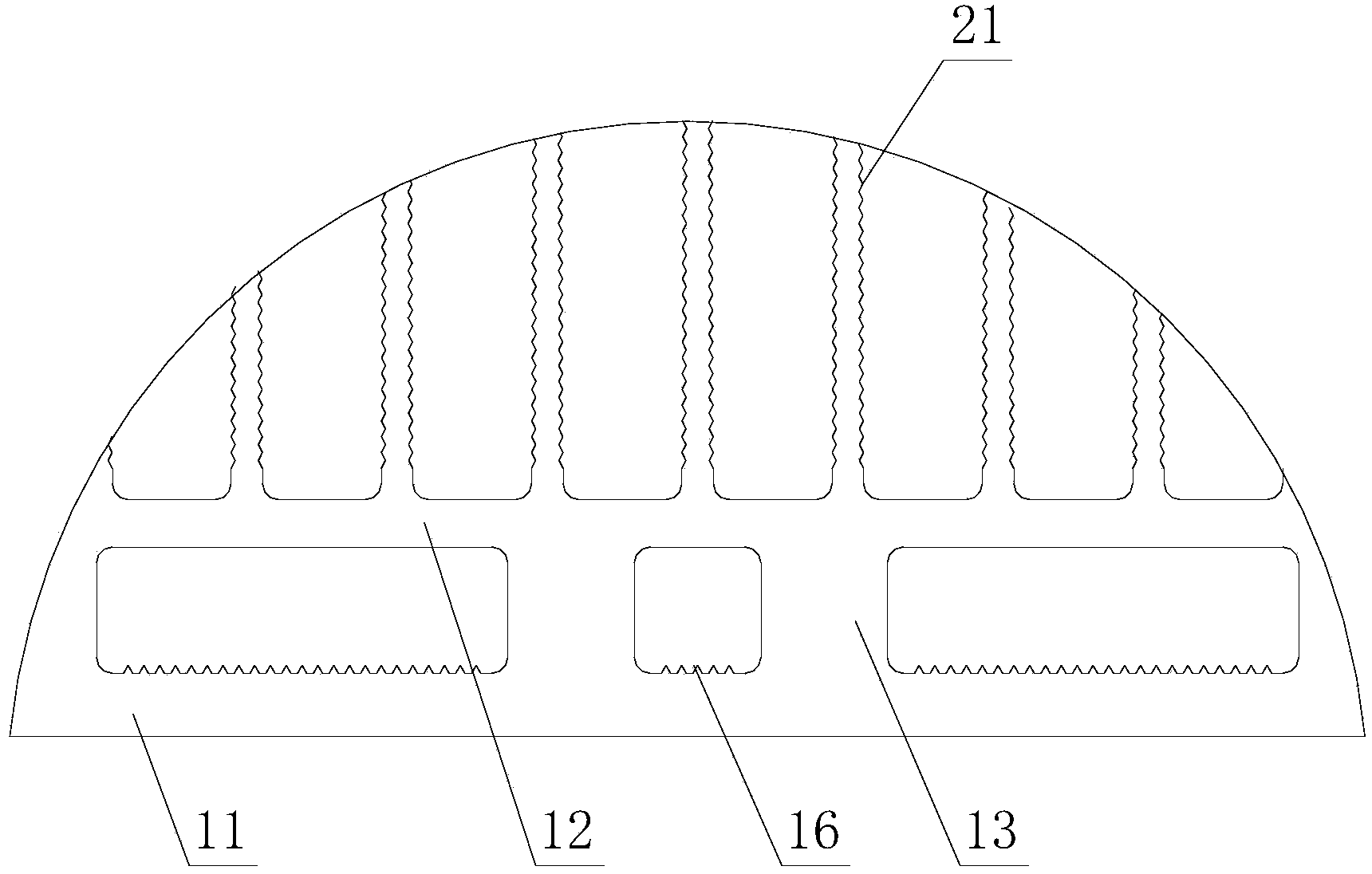

[0019] The surface of the heat dissipation fin 2 is provided with capillary channels 21, which increases the heat dissipation area; the heat dissipation fins 2 are arranged on the top plate 12 of the heat conduction plate 1 at equal intervals along the long side of the heat conduction plate 1, and from the middle to both sides in sequence from high to high. Low arrangement, its role is to set the height of the heat dissipation fins according to the heat of each position, saving profiles.

[0020] A sealed cavity is provided inside the heat conduction plate 1, and the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com