On-site pouring maintenance method of survey monument in high-latitude area and low-temperature environment

A low-temperature environment, high-latitude technology, applied in the direction of measuring point marks, permanent markers, landmarks, etc., can solve the problems of slow concrete hardening speed, affect the quality of concrete, and no longer increase in strength, so as to shorten the setting time, simple and fast Heat release, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

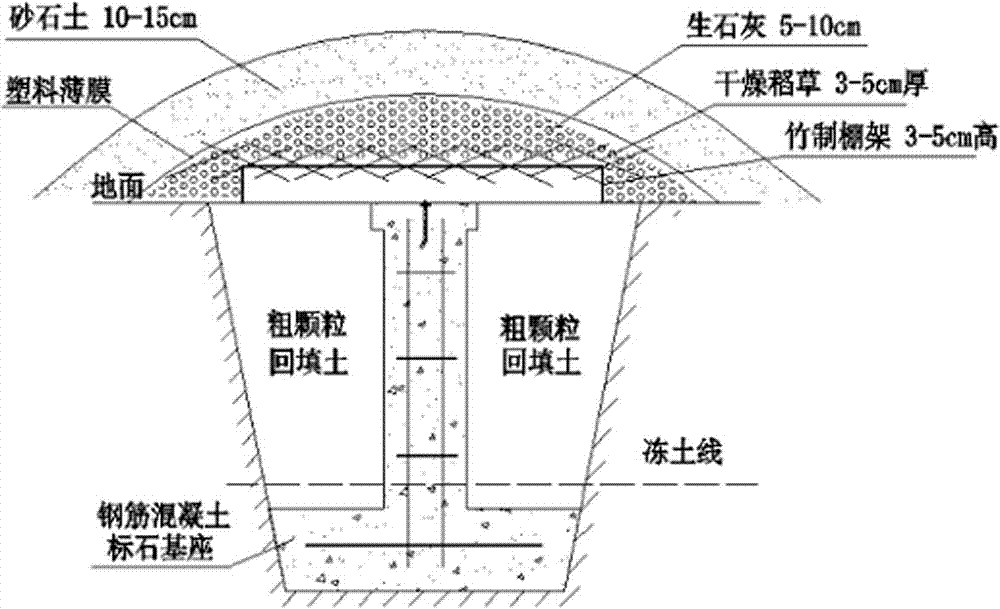

[0024] root tree figure 1 Shown, a kind of high-latitude area low temperature environment surveys the spot watering maintenance method of the marker stone: its steps are as follows:

[0025] (1) Optimal cement varieties;

[0026] (2) Choose sand and gravel with small particle size, sand diameter 1.1---1.5mm, stone diameter 1---3cm, properly reduce the water-cement ratio to form concrete;

[0027] (3) When the on-site watering is completed to measure the marked stones, the ratio of water, ash, and sand to gravel is 1:2.5:7, and the water at a temperature of 20-25°C is used to fully stir, and the water is poured quickly before the temperature is lower than 15°C;

[0028] (4) Without taking out the formwork, backfill the soil directly to make it level with the ground;

[0029] (5) At a height of 3-5cm from the standard surface, make a bamboo pole support frame;

[0030] (6) Cover the bamboo pole support frame with 3---5cm thick dry straw;

[0031] (7) Cover the straw with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com