Flexible boundary load test device

A technology of loading test device and flexible boundary, which is applied in the measurement device, using stable tension/pressure to test the strength and strength characteristics of materials, etc. Guaranteed effect of accuracy and authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

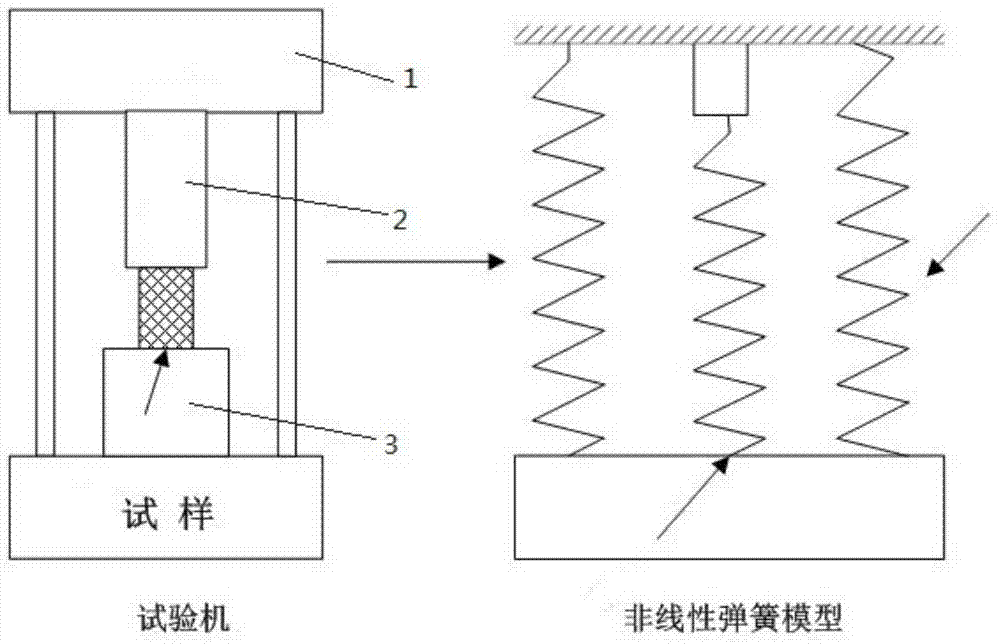

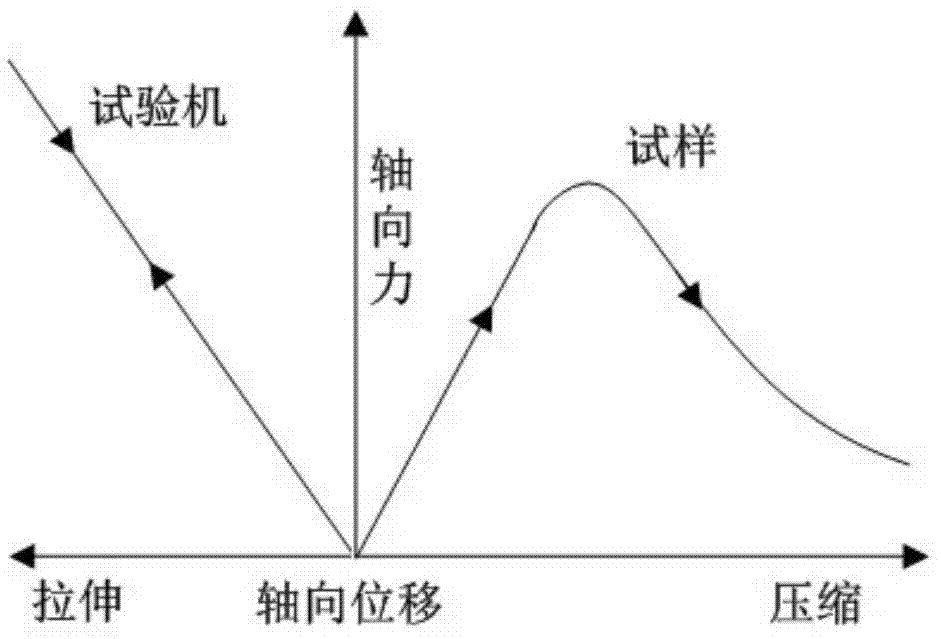

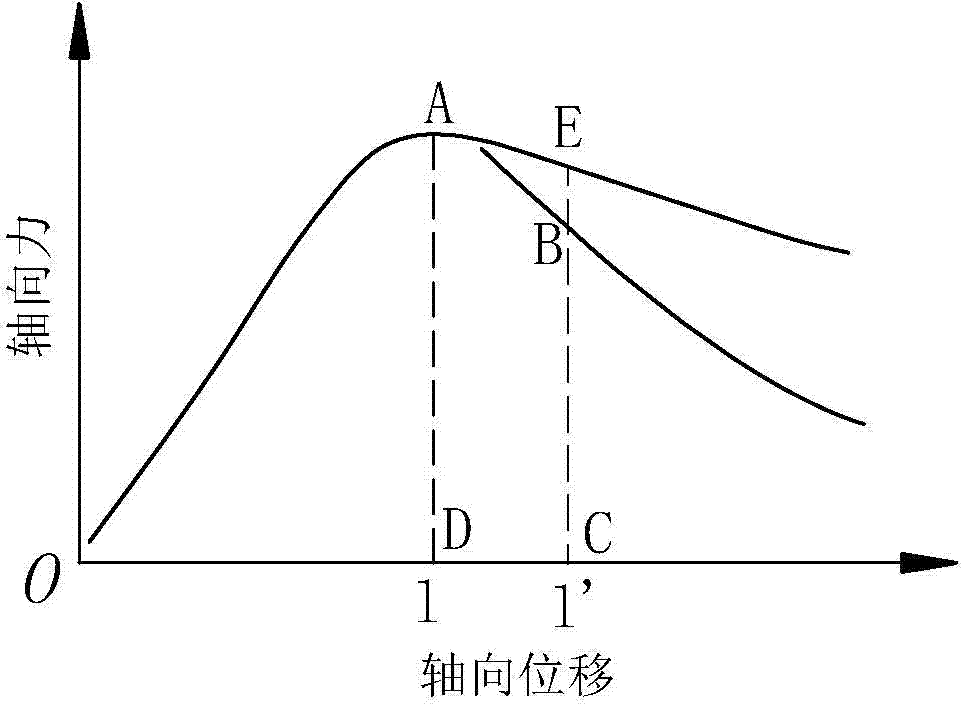

Method used

Image

Examples

Embodiment Construction

[0035] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0036] see Figure 4-6 In the shown flexible boundary loading test device, the base is composed of a base plate 11 folded around and a sleeve 12, and a disc spring 13 and a pressure bearing plate 14 are placed in the sleeve, and the pressure bearing plate 14 acts as a bearing for the testing machine The parts that are in direct contact with the jack, and the sleeve 12 need to be subjected to surface heat treatment during the production process, so that the surface hardness is not less than HRC50; there is a support piece 15 between the sleeve 12 and the base steel plate 11, and the support piece 15 is evenly distributed on the sleeve. The periphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com