Detection system and method used for motor stator winding

A detection system, motor stator technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of affecting detection efficiency, increasing detection cost, mechanical wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

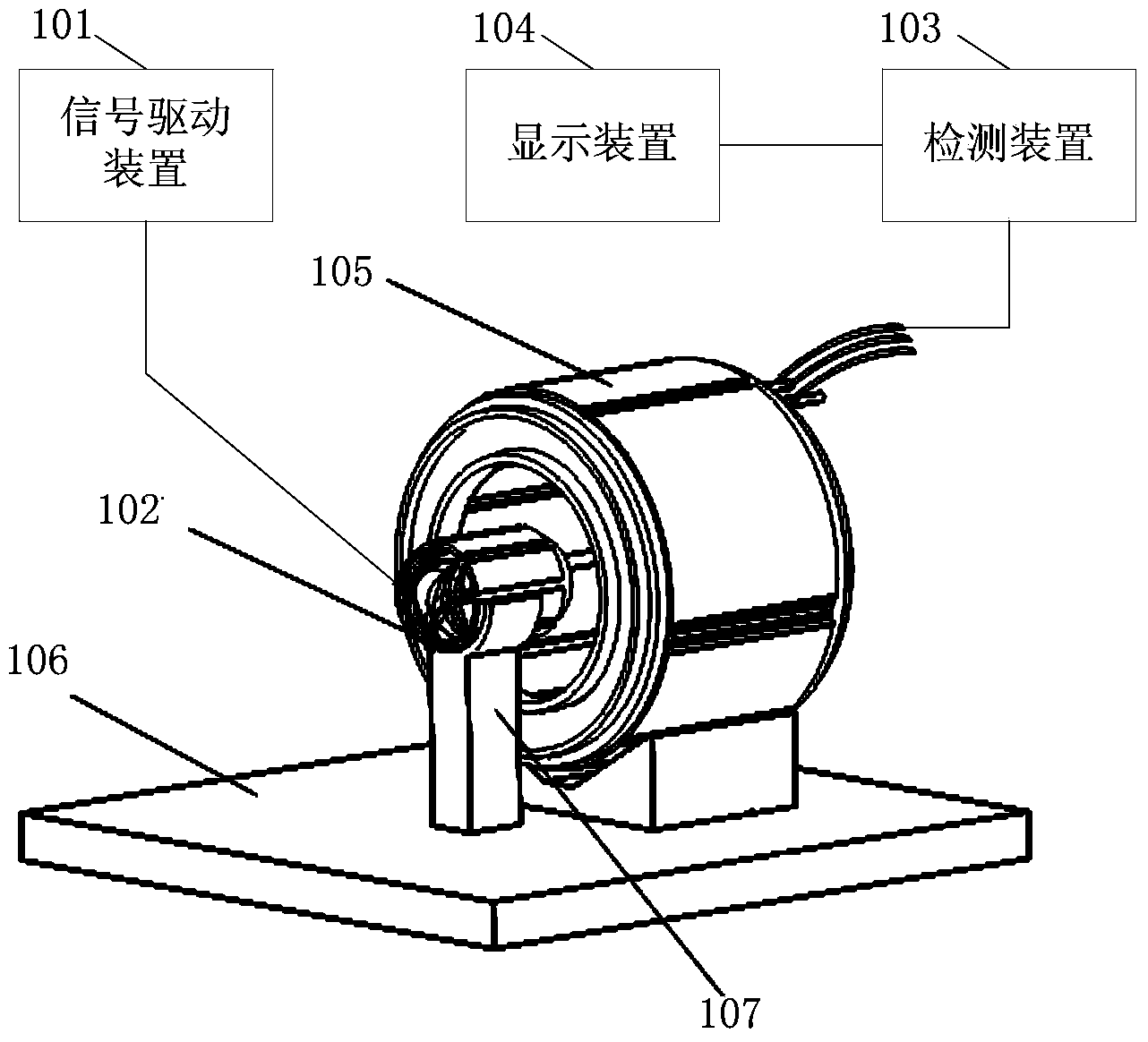

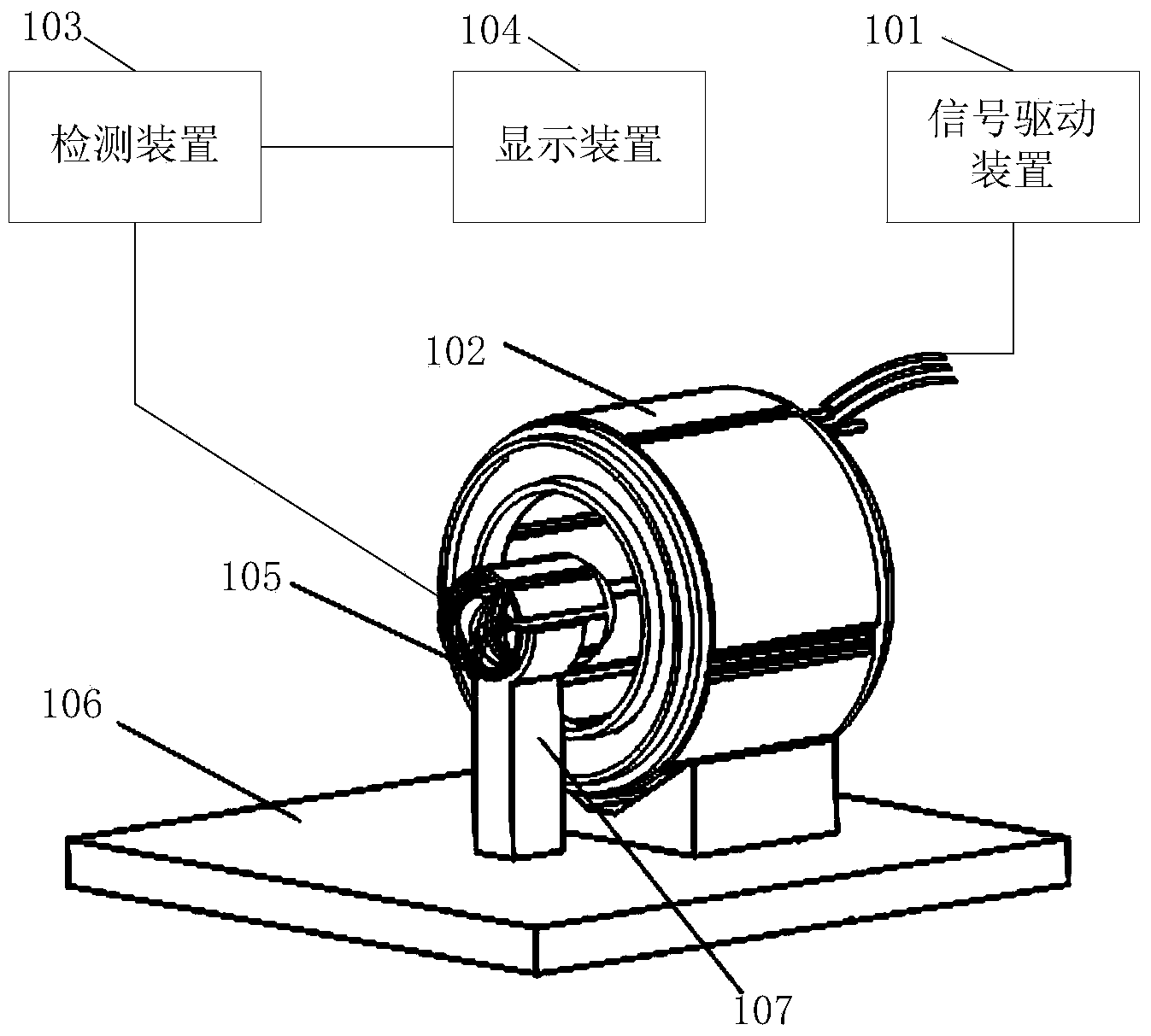

[0039] combine figure 1 Shown is a schematic structural diagram of a detection system for a motor stator group of an inner rotor structure motor according to the present invention, and figure 2 Shown is a schematic structural diagram of a detection system for a motor stator group of an outer rotor structure motor according to the present invention, the detection system may include: a signal drive device 101, an electromagnetic excitation device 102, a detection device 103 and a display device 104, wherein,

[0040] The signal driving device 101 is connected to one end of the electromagnetic excitation device 102, and sends the generated multi-phase alternating current signal to the electromagnetic excitation device 102 (specifically, an electromagnetic excitation coil), so that the electromagnetic excitation device 102 generates a first rotating magnetic field. At this time, since the other end of the electromagnetic excitation device 102 is close to the magnetic pole surface...

Embodiment 2

[0056] Such as Figure 4 As shown, it is a flow chart of a detection method for motor stator windings in the present invention, the detection method can be applied to the detection system of the motor stator windings described in the first embodiment above, because the detection system can include: a signal drive device , electromagnetic excitation device, detection device and display device, then the specific steps of the detection method may include:

[0057] Step S301: The starting signal driving device sends a multiphase alternating current signal to the electromagnetic excitation device, so that the electromagnetic excitation device generates a first rotating magnetic field.

[0058] Step S302: Using the first rotating magnetic field to excite the iron core of the stator to be measured to generate a second rotating magnetic field, so that the outgoing terminals of each phase winding of the stator to be measured generate induced electromotive force.

[0059] Step S303: Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com