Processing box

A process box and outlet technology, applied in the field of process boxes, can solve the problems of large contact force on the electrical contact portion 181, unfavorable cleaning of contaminants, increased use costs for users, etc., to improve electrical connection stability and electrical connection fault tolerance. performance, improve the fault tolerance of electrical connections, and protect the effect of electrical connection structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

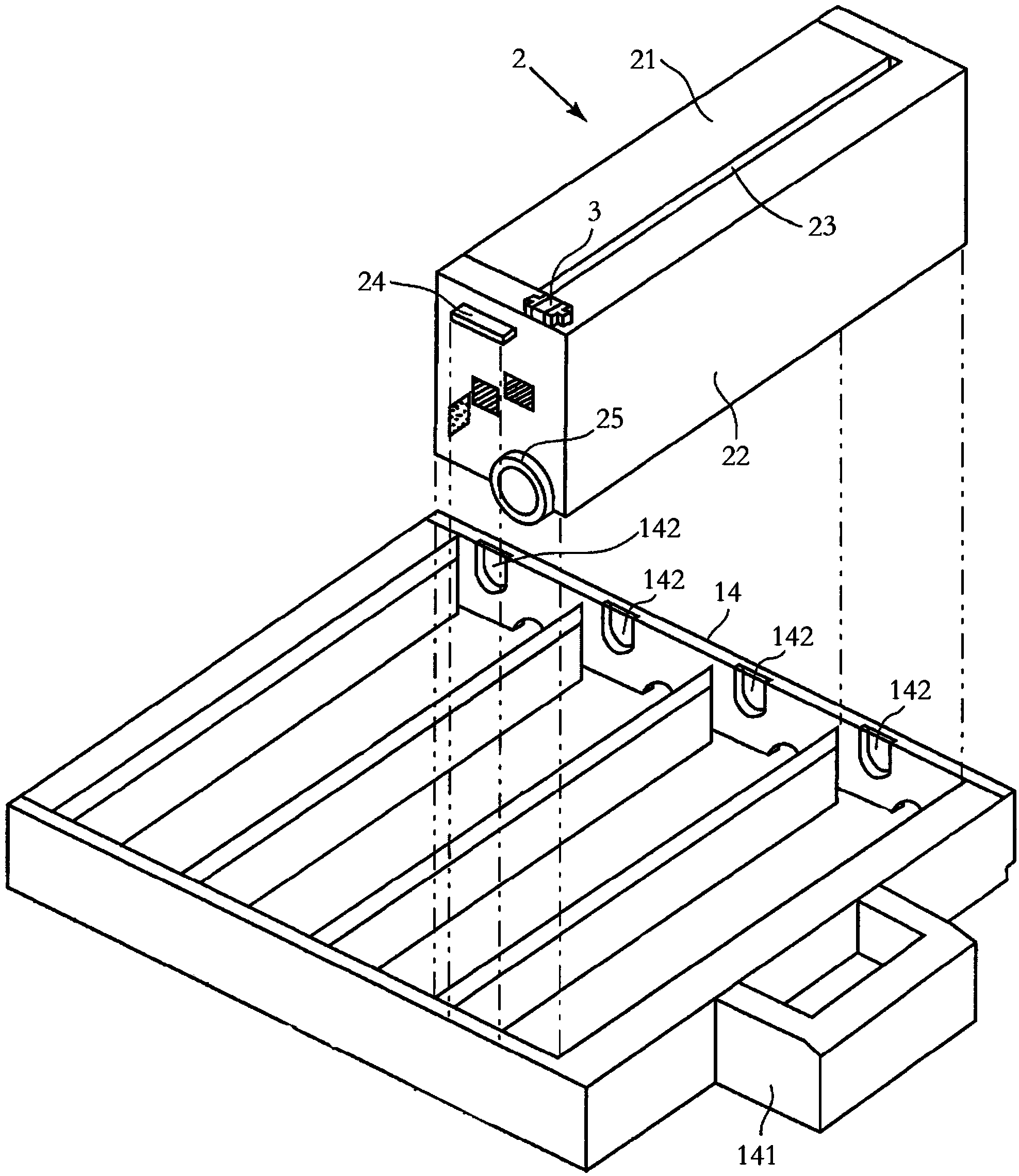

[0044] refer to Figure 7 with Figure 8 , the process box 4 includes a developing unit 41 and a drum unit 42, the developing unit 41 is installed on one side of the drum unit 42, the developing unit 42 casing surrounds a powder bin containing carbon powder, and a developing unit is provided at the opening of the powder bin. rollers (not shown). The shell of the drum unit 42 surrounds a waste toner bin containing waste toner, a photosensitive drum (not shown) is arranged at the opening of the waste toner bin, and a drive assembly 53 is installed at the end of the photosensitive drum. The drive assembly 53 includes a mounting part 532, three protrusions 531 of non-twisted shape are formed in the axial direction on the mounting part 532, and the three protrusions 531 are evenly arranged on the outer end of the mounting part 532 along the circumferential direction, and the driving assembly 53 is used for Receiving external rotational driving force, the photosensitive drum and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com