Greenhouse roller blind control system and working method thereof

A control system and working method technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of overrun, personal injury, equipment damage, etc., to improve the degree of automation and avoid damage accidents , the effect of saving personnel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

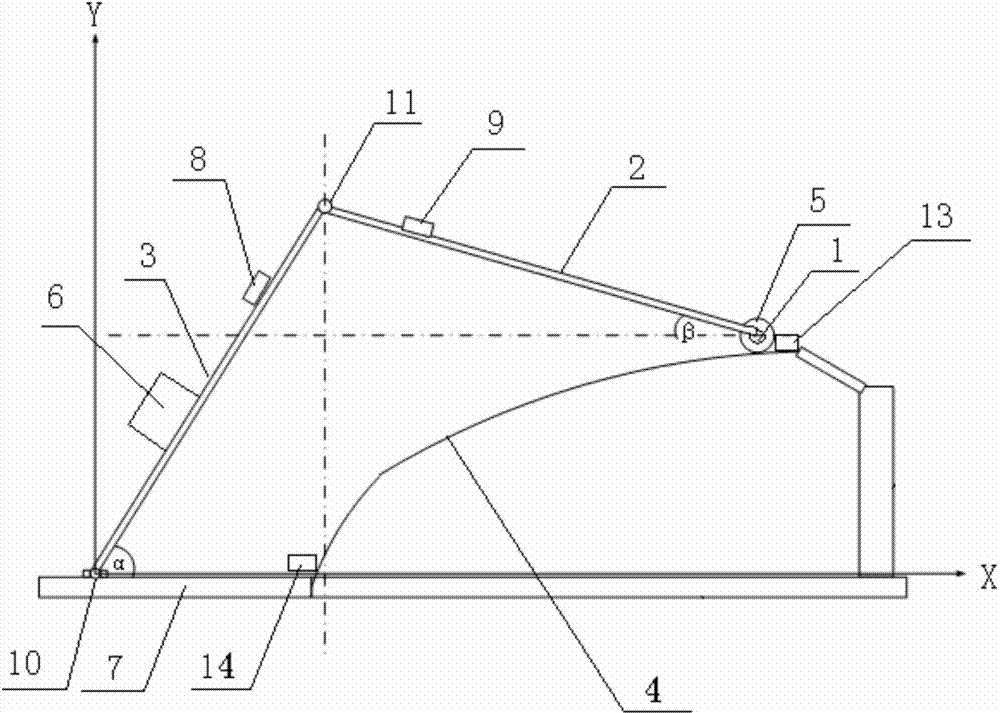

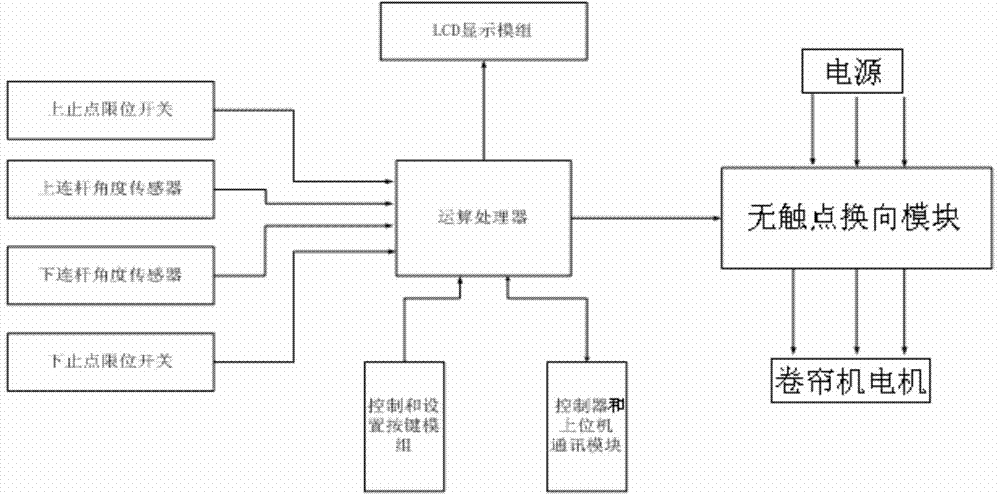

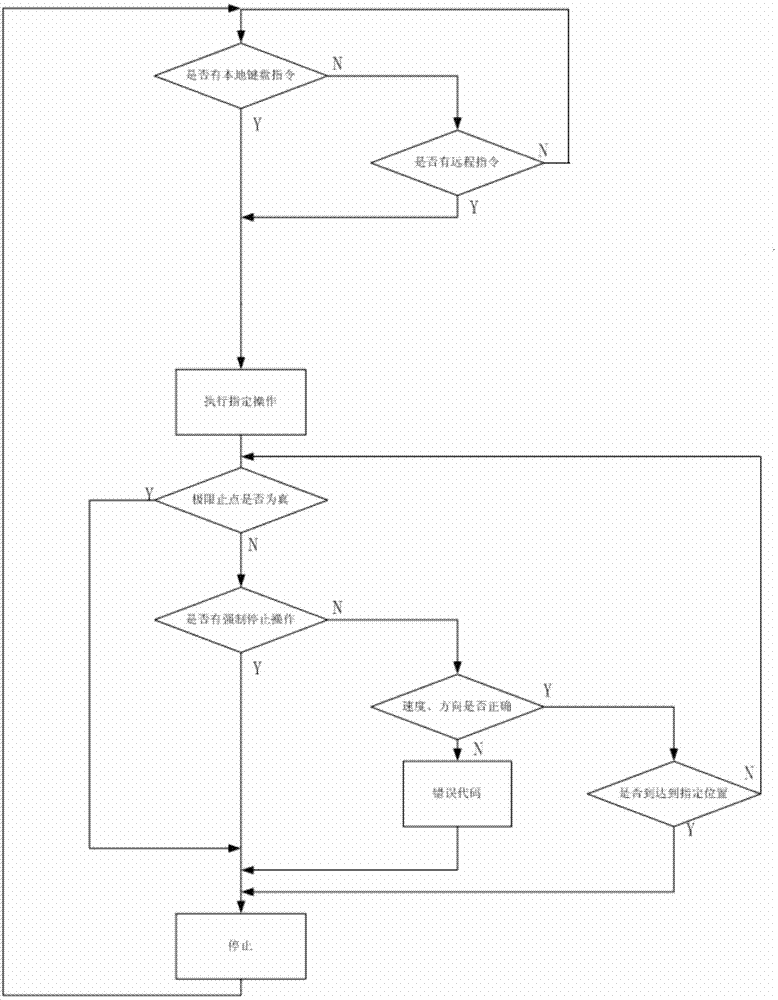

[0025] Embodiment: A greenhouse roller shutter control system, including a roller shutter controller 6, a contactless reversing module, an upper link 2 of a roller shutter, a lower link 3 of a roller shutter, a hinge a10, a hinge b11, and a roller shutter 1. Angle sensor a8, angle sensor b9, top dead center limit switch 13 and bottom dead center limit switch 14; one end of the upper connecting rod 2 of the shutter machine is installed on the ground 7 at the front end of the shed film 4 through the hinge a10, The other end is connected to one end of the lower connecting rod 3 of the roller blind machine through the hinge b11, and the roller blind machine controller 6 and the angle sensor a8 are installed on the upper connecting rod 2 of the roller blind machine; The curtain machine 1, the angle sensor b9 is installed on the lower connecting rod 3 of the roller shutter machine; the output shaft of the shutter machine 1 is equipped with a thermal insulation quilt 5; the thermal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com