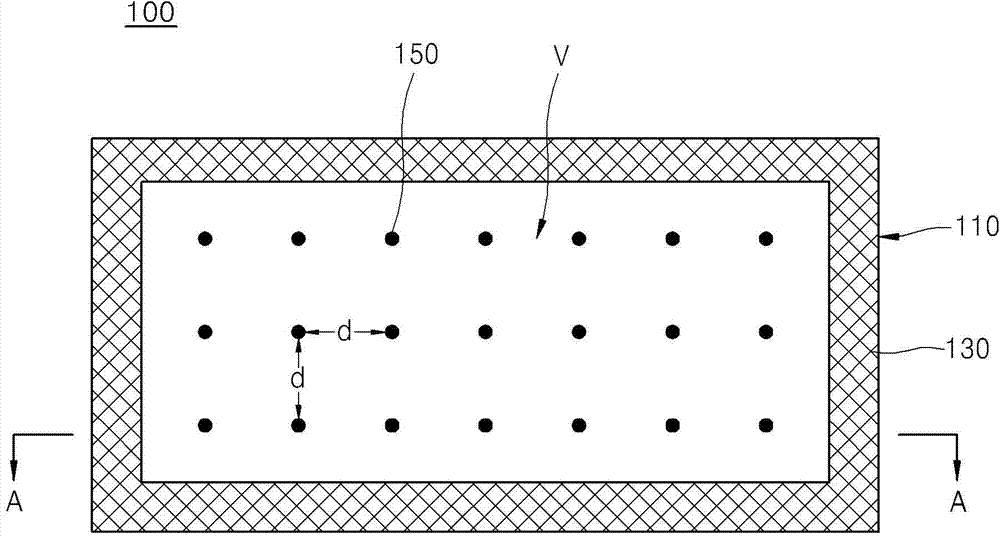

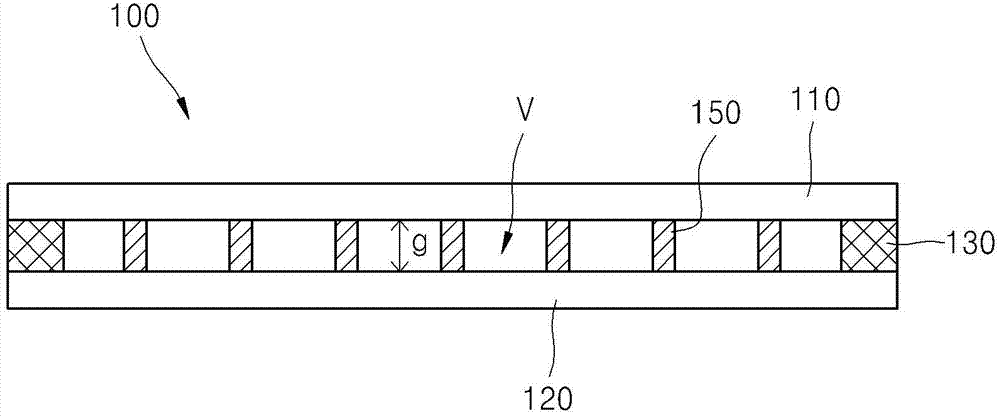

Vacuum glass panel having getter filler and method of manufacturing same

A technology of vacuum glass and glass plates, applied in chemical instruments and methods, glass/slag layered products, improvement of windows/doors, etc., can solve problems such as defects, thick thickness, prolonging process time, etc., to save costs and improve Durability, the effect of improving the gas adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

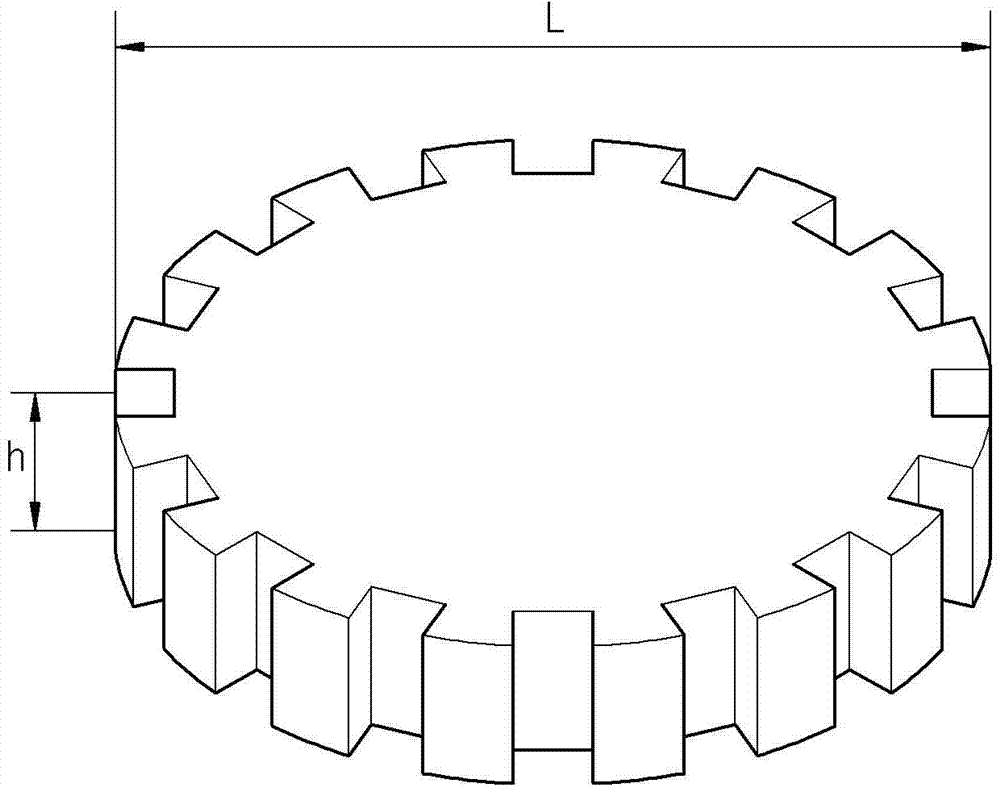

[0067] A thin sheet comprising a Zr alloy with a thickness of 0.1mm is prepared and punched to prepare a filler for Zr alloy absorption, wherein the above-mentioned Zr alloy is composed of 84 parts by weight of Zr and 16 parts by weight of Zr alloy relative to 100 parts by weight of Zr alloy. Al composition.

Embodiment 2

[0069] A filler for Zr alloy absorption was prepared in the same manner as in Example 1, except that 70 parts by weight of Zr and 30 parts by weight of Al were used with respect to 100 parts by weight of Zr alloy.

Embodiment 3

[0071] A filler for Zr alloy absorption was prepared in the same manner as in Example 1, except that 90 parts by weight of Zr and 10 parts by weight of Al were used with respect to 100 parts by weight of Zr alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com