A precision seeder for Panax notoginseng

A planter, precision technology, applied in the field of agricultural machinery, can solve the problems of high planting cost, low work efficiency, and high labor intensity of Panax notoginseng, and achieve the effect of improving seeding efficiency, high work efficiency, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

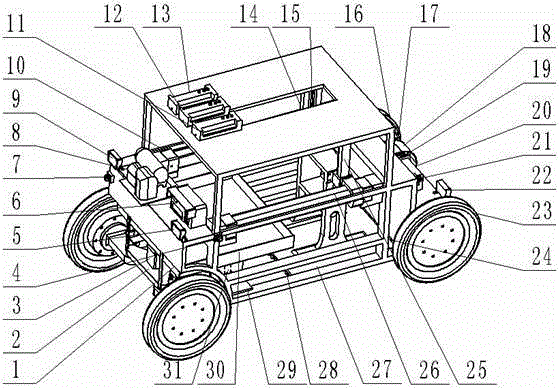

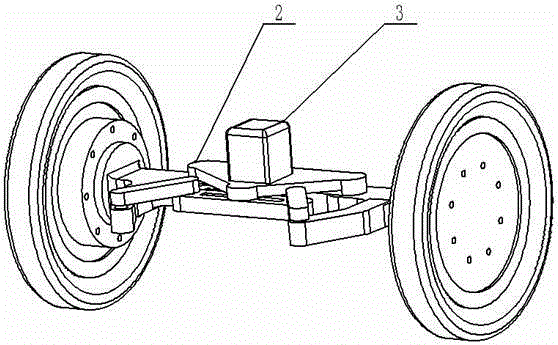

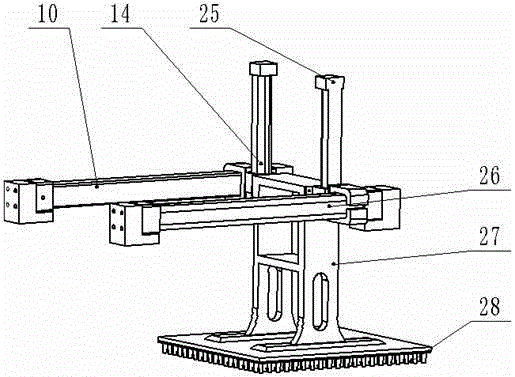

[0029] Embodiment 1: as Figure 1-7As shown, a Panax notoginseng precision seeder includes frame 1, front wheel steering mechanism 2, front wheel steering drive servo motor 3, emergency stop button I4, lighting lamp I5, independent power supply of air compressor 6, emergency stop button II7 , Air compressor 8, lighting lamp Ⅱ 9, rodless cylinder Ⅰ 10, pneumatic solenoid valve Ⅰ 11, pneumatic solenoid valve Ⅱ 12, pneumatic solenoid valve Ⅲ 13, rodless cylinder Ⅱ 14, emergency stop button Ⅲ 15, lighting lamp Ⅲ 16, power supply 17, chain transmission mechanism Outer cover 18, chain transmission mechanism 19, rear wheel drive servo motor 20, emergency stop button IV 21, lighting lamp IV 22, driving wheel mechanism 23, soil covering plate 24, rodless cylinder III 25, rodless cylinder IV 26, seed suction head mounting plate 27, Seed suction head 28, cylinder support bracket 29, seed box 30, double-acting cylinder 31; the front wheel steering mechanism 2 is installed in front of the ...

Embodiment 2

[0030] Embodiment 2: as Figure 1-7 As shown, a Panax notoginseng precision seeder includes frame 1, front wheel steering mechanism 2, front wheel steering drive servo motor 3, emergency stop button I4, lighting lamp I5, independent power supply of air compressor 6, emergency stop button II7 , Air compressor 8, lighting lamp Ⅱ 9, rodless cylinder Ⅰ 10, pneumatic solenoid valve Ⅰ 11, pneumatic solenoid valve Ⅱ 12, pneumatic solenoid valve Ⅲ 13, rodless cylinder Ⅱ 14, emergency stop button Ⅲ 15, lighting lamp Ⅲ 16, power supply 17, chain transmission mechanism Outer cover 18, chain transmission mechanism 19, rear wheel drive servo motor 20, emergency stop button IV 21, lighting lamp IV 22, driving wheel mechanism 23, soil covering plate 24, rodless cylinder III 25, rodless cylinder IV 26, seed suction head mounting plate 27, Seed suction head 28, cylinder support bracket 29, seed box 30, double-acting cylinder 31; the front wheel steering mechanism 2 is installed in front of the...

Embodiment 3

[0032] Embodiment 3: as Figure 1-7 As shown, a Panax notoginseng precision seeder includes frame 1, front wheel steering mechanism 2, front wheel steering drive servo motor 3, emergency stop button I4, lighting lamp I5, independent power supply of air compressor 6, emergency stop button II7 , Air compressor 8, lighting lamp Ⅱ 9, rodless cylinder Ⅰ 10, pneumatic solenoid valve Ⅰ 11, pneumatic solenoid valve Ⅱ 12, pneumatic solenoid valve Ⅲ 13, rodless cylinder Ⅱ 14, emergency stop button Ⅲ 15, lighting lamp Ⅲ 16, power supply 17, chain transmission mechanism Outer cover 18, chain transmission mechanism 19, rear wheel drive servo motor 20, emergency stop button IV 21, lighting lamp IV 22, driving wheel mechanism 23, soil covering plate 24, rodless cylinder III 25, rodless cylinder IV 26, seed suction head mounting plate 27, Seed suction head 28, cylinder support bracket 29, seed box 30, double-acting cylinder 31; the front wheel steering mechanism 2 is installed in front of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com