A kind of self-supporting PVDF homogeneous microporous tubular membrane and preparation method thereof

A tubular membrane, self-supporting technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high preparation cost and the performance of membrane products needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

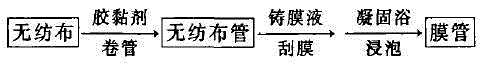

Method used

Image

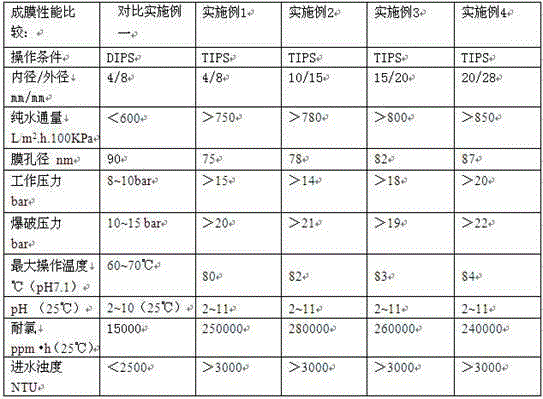

Examples

Embodiment 1

[0052] Film-making solution preparation: mix polyvinylidene fluoride resin, inorganic powder and diluent at 60°C to form a uniform powder; film-making components and proportions are: polyvinylidene fluoride resin 12wt%; diluent 26wt%; the rest is inorganic pink;

[0053] The weight average molecular weight of polyvinylidene fluoride resin is 150,000-180,000 daltons, and the crystallinity is 50%; the specific surface area of inorganic powder is 50-500m 2 / g, average particle size 0.005-0.1μm.

[0054] Inorganic powder is talcum powder;

[0055] The diluent is a co-solvent composed of a weakly acting potential solvent and a strongly acting potential solvent in a mass ratio of 3:1;

[0056] Wherein the potential solvent of weak action is benzyl benzoate, and the potential solvent of strong action is triethyl glycerate and monoethyl glyceride.

[0057] Film making: The film making powder is fed into the film forming unit including twin-screw mixer and melt pump through forced...

Embodiment 2

[0061] Film-making liquid preparation: mix polyvinylidene fluoride resin, inorganic powder and diluent at 85°C to form a uniform powder; the composition and ratio of film-making liquid are: polyvinylidene fluoride resin 24wt%; diluent 15wt%;

[0062] The weight average molecular weight of polyvinylidene fluoride resin is 180,000-200,000 Daltons, and the crystallinity is 55%; the specific surface area of inorganic powder is 50-500m 2 / g, average particle size 0.1-0.2μm.

[0063] The rest is inorganic powder;

[0064] The inorganic powders are bentonite and kaolin.

[0065] The diluent is a co-solvent composed of a weakly acting potential solvent and a strongly acting potential solvent in a mass ratio of 4.5:1;

[0066] Wherein the potential solvent with weak action is dibutyl sebacate, and the potential solvent with strong action is diethyl glycerate.

[0067] Film making: The film making powder is fed into the film forming unit including twin-screw mixer and melt pump thr...

Embodiment 3

[0071] Preparation of film-making powder: mix polyvinylidene fluoride resin, inorganic powder and diluent at 60-85°C to form a uniform powder; the composition and proportion of film-making liquid are: polyvinylidene fluoride resin 18wt%; diluent 20wt %;

[0072] The weight average molecular weight of polyvinylidene fluoride resin is 220,000-230,000 daltons, and the crystallinity is 60%; the specific surface area of inorganic powder is 50-500m 2 / g, average particle size 0.3-0.5μm;

[0073] The inorganic powder is calcium carbonate, talc, bentonite, kaolin or silica powder.

[0074] The diluent is a co-solvent composed of a weakly acting potential solvent and a strongly acting potential solvent in a mass ratio of 4:1;

[0075] Wherein the potential solvent of weak action is dibutyl sebacate, and the potential solvent of strong action is benzophenone.

[0076]Film making: The film making powder is fed into the film forming unit including twin-screw mixer and melt pump throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com