Optimisation of a device for painting work pieces

A workpiece and coating technology, applied in the direction of cleaning device, spraying device, liquid spraying device, etc., can solve the problem of inability to coat paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

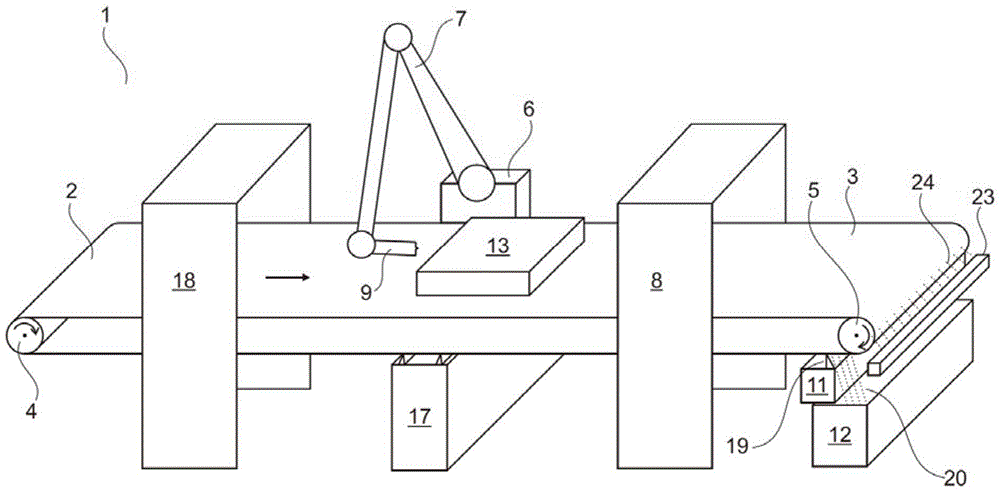

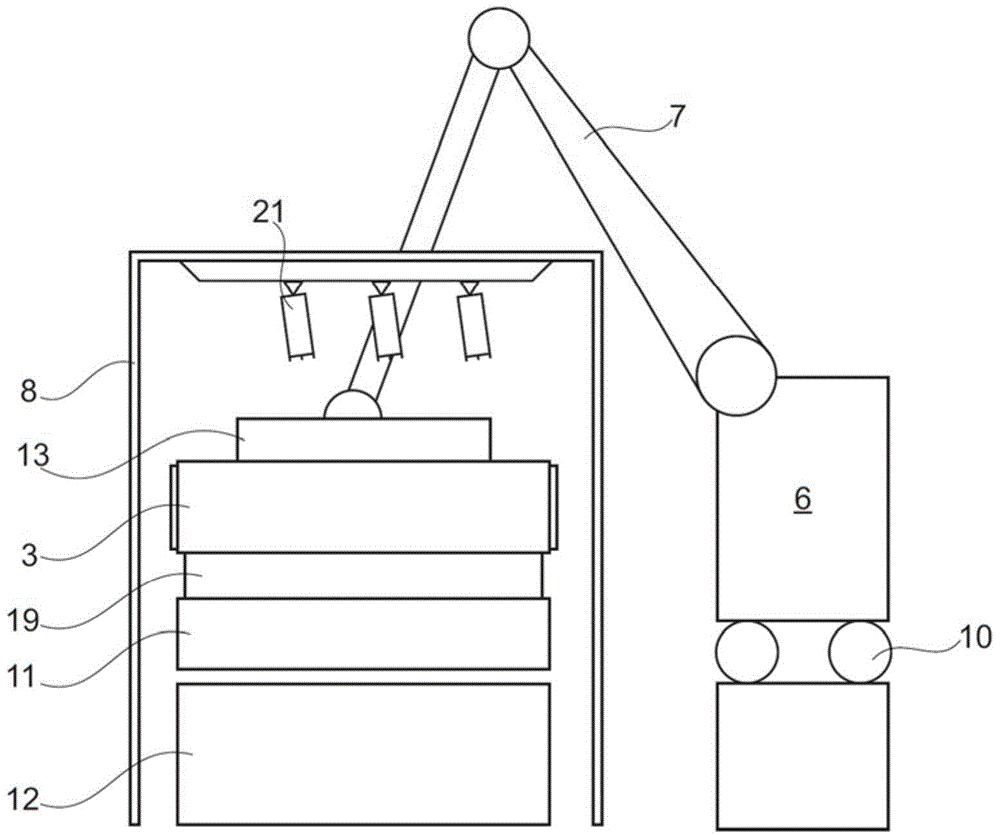

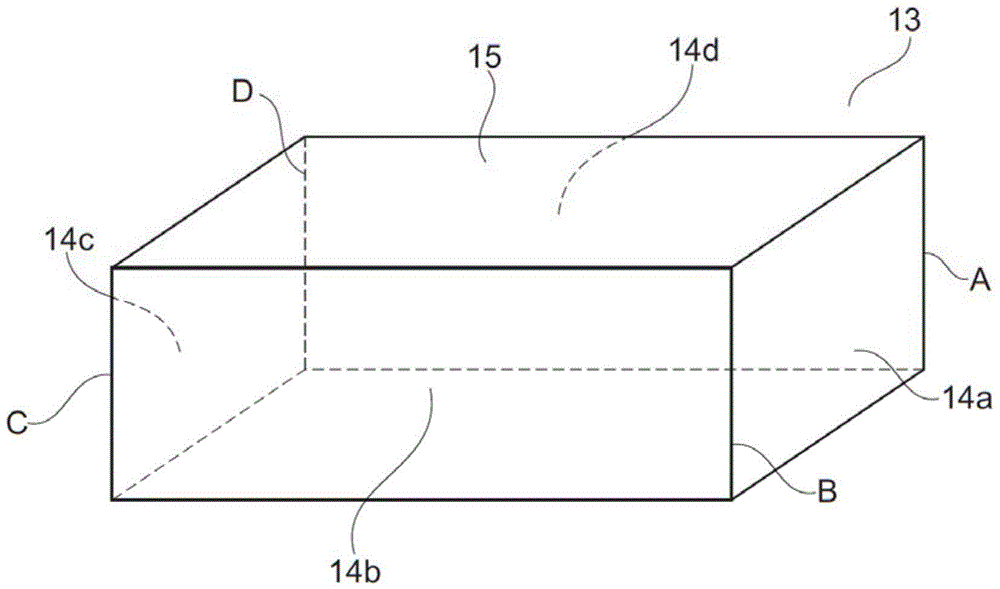

[0073] figure 1 is a side view of an apparatus for coating workpieces according to the invention. The device 1 for coating workpieces has a simple structure and basically consists of the following parts: a belt conveyor 2 , a paint spraying robot 6 and a surface spraying machine 8 , and a three-dimensional part detection device (3D part detection device) 18 .

[0074] The belt conveyor 2 has a conveyor belt 3 , a first tail pulley 4 and a second tail pulley 5 . The conveyor belt 3 is driven by one of the first tail pulley 4 and the second tail pulley 5 . The conveyor belt 3 transports the workpieces to be coated from the three-dimensional part inspection device 18 to the paint spraying robot 6 and then to the surface spraying machine 8 (see arrow on the conveyor belt 3 ). During the following coating process, the fully coated workpieces are conveyed by the conveyor belt 3 .

[0075] The paint removal apparatus 11 (paint removal apparatus) has a scraping device 19 (scraping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com