Orienting sorting ordering feeding system for fresh corncobs and orienting sorting ordering method thereof

A technology for fresh corn and sorting system, applied in sorting and other directions, can solve the problems of overall size, large structure, low work efficiency, high procurement and use costs, and achieve a high degree of automation, low production costs, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

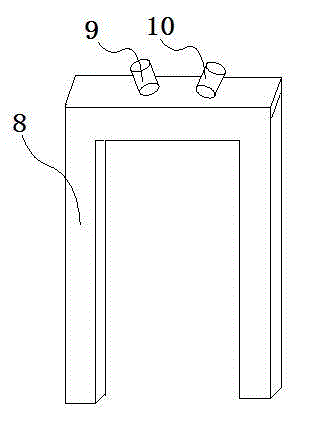

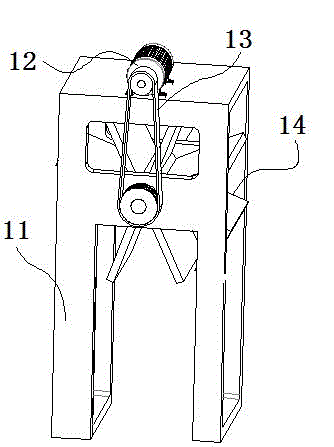

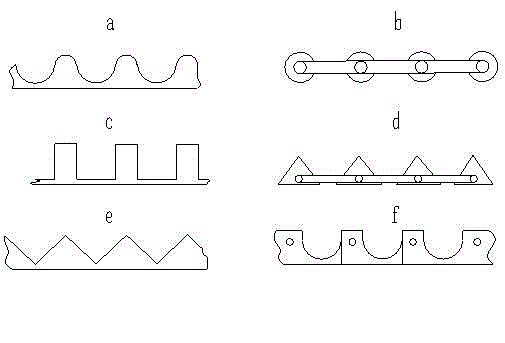

[0042] like figure 1 Shown: The directional sorting and sorting feeding system for fresh corn ears includes fresh corn ear sorting and feeding device Ⅰ, single row transmission device Ⅱ, corn online size and direction detection device Ⅲ, corn sorting device Ⅳ, and corn recycling device Ⅴ , Forward single-row conveying device VI, reverse single-row conveying device VII and computer VIII, the sorting and feeding device I and single-row conveying device II, corn online size and direction detection device III, and directional sorting device IV are installed in sequence, The single row conveying device II is placed on the side of the corn cob discharge direction of the sorting and feeding device I, and the corn online size and direction detection device III and the corn sorting device IV are installed above the single row conveying device II, and the corn sorting device IV is located on the corn line size The rear side of the direction detection device III, the corn recovery device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com