Boring tool used for machining deep holes of turbine sleeves and deep hole machining method

A technology for processing tools and steam turbines, which is applied in the direction of manufacturing tools, boring/drilling, and metal processing equipment. It can solve the problems of tool chipping, breaking, and poor heat dissipation conditions of tools, so as to prevent damage to workpieces, and is convenient and fast to use. The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

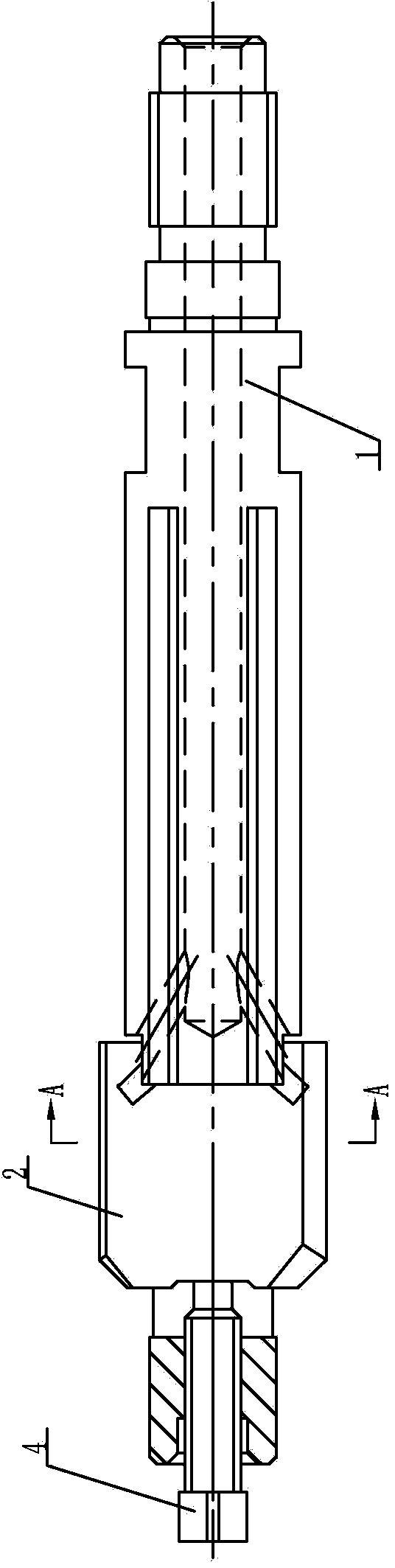

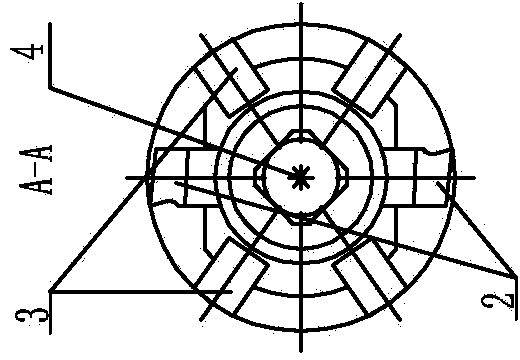

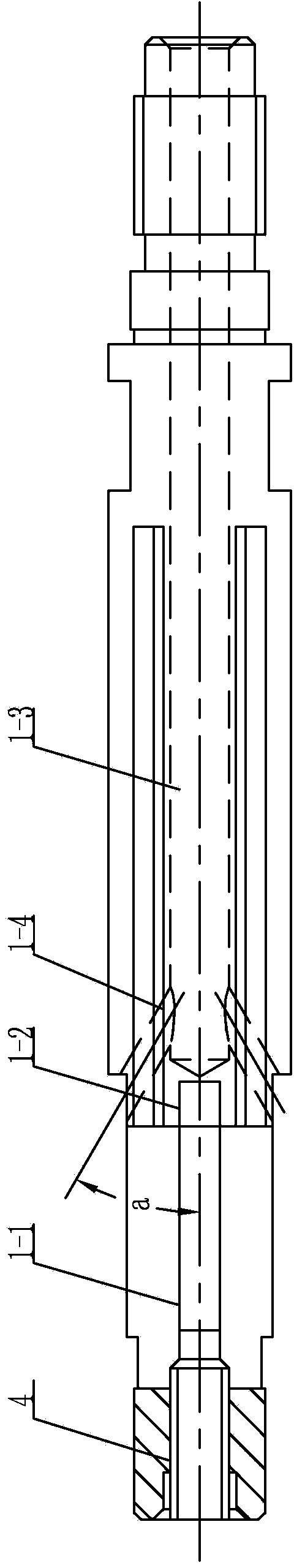

[0016] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment, the deep hole boring processing tool for the steam turbine sleeve described in this embodiment, the boring tool includes a boring tool bar 1, a boring tool 2 and four guide blocks 3, the guide blocks 3 are rectangular Block body, one side of the guide block 3 is processed with an arc-shaped surface 3-1, the left end of the boring bar 1 is processed with a long groove 1-1 to the right, and the outer circle of the boring bar 1 is close to the right end of the long groove 1-1 There are two card slots 1-2 in symmetrical processing, the right end of the boring bar 1 is processed to the left with coolant flow holes 1-3, and the left end of the coolant flow holes 1-3 is evenly distributed in the radial direction with multiple coolant ejection holes 1-4, and the angle formed by the center line of each coolant spray hole 1-4 along the length direction and the center line of the boring bar 1 al...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 , figure 2 , Figure 4-Figure 7 Describe this embodiment, the deep hole boring machining tool for steam turbine sleeve described in this embodiment, the boring tool 2 is a cuboid, and the cuboid is divided into an upper end face 2-1, a lower end face 2-2, and a left end face 2 -3, the right end face 2-4, the front end face 2-5 and the rear end face 2-6, the upper end face 2-1 near the cuboid is processed with the first cutting tool 2-7, and the lower end face 2-2 near the cuboid is processed with the second Cutter 2-8, between the first cutter 2-7 and the second cutter 2-8 is a handle 2-9, and the cutter head of the first cutter 2-7 and the cutter head of the second cutter 2-8 are all close to the cuboid The angle formed by the main cutting edge of the first tool 2-7 and the upper end surface 2-1 is 45°, and the angle formed by the main cutting edge of the second tool 2-8 and the lower end surface 2-2 is 45°, th...

specific Embodiment approach 3

[0018] Specific implementation mode three: combination Figure 1-Figure 7 Describe this embodiment, a deep hole boring processing tool for steam turbine sleeve described in this embodiment, the cutting edge of the first cutting edge and the cutting edge of the second cutting edge and the arc surface 3 of the four guide blocks 3 -1 On the arc of the same circle, the length of the boring tool 2 is L, the value of L is 35mm, the distance between the tip of the first blade and the tip of the second blade is 20mm-30mm, and other specific Embodiment 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com