Equipment and method for producing reflective film with microprism structure by extrusion method

A technology of microprism and reflective film, which is applied in the field of production of microprism structure reflective film by extrusion method, which can solve the problem of inability to ensure that the splicing seam is absolutely flat and flawless, and the overall uniformity of the thickness of the large-area electroformed nickel plate is completely consistent, etc. problems, to achieve the effect of ensuring service life, increasing material temperature and protecting service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

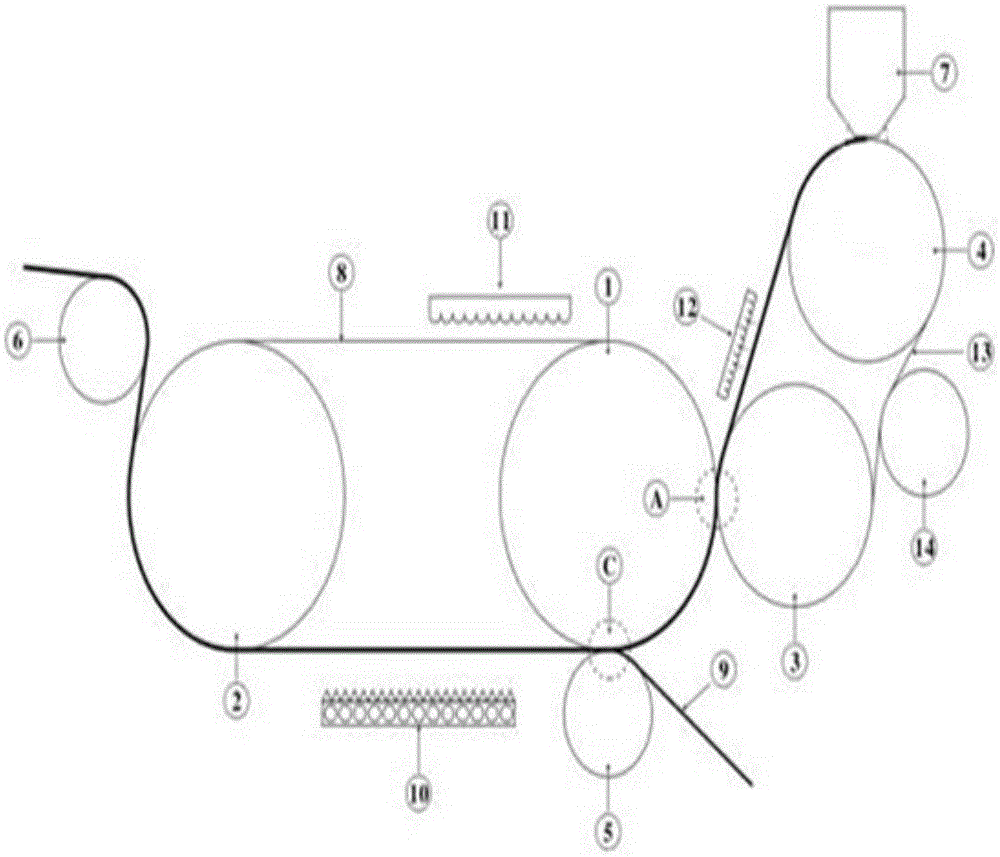

[0025] Extrusion method of the present invention produces the equipment of microprism structure reflective film, as figure 1 Shown, its technical scheme is:

[0026] 1) The ring-shaped mold belt 8 runs clockwise around the heating roller 1 and the cooling roller 2. The two rollers are placed flat and have a certain tension between them to ensure that the ring-shaped mold belt 8 is tensioned without damage;

[0027] 2) On the right side of the heating roller 1 are the silicone roller 3 and the metal roller 4 attached to the high-temperature fiber belt 13, and the silicone roller 3 is pressed against the heating roller 1 through the cylinder pressure;

[0028] 3) A far-infrared heating device 12 is set above the left side molding entrance A of the fiber strip 13, which plays a role of heat preservation and warming, so as to ensure that the plastic melt has a sufficient temperature before molding;

[0029] 4) Above the metal roller 4 is the extrusion die 7, the die lip of the ex...

Embodiment 2

[0036] The preparation method of embodiment 2 microprism structure reflective film

[0037] (1) extrusion coating

[0038] The polycarbonate resin with a melt index greater than 20 / g (10min) and a melt viscosity less than 800 Pa*s is extruded on the high temperature resistant fiber tape 13 wrapped with a metal roller 4 through the extrusion die 7 without stretching, and extruded The extrusion temperature of the die head 7 was 285°C, and the temperature of the metal roll 4 was 300°C.

[0039] The non-stretch extrusion coating means that the gap between the die lip and the fiber tape 13 wrapped on the metal roller 4 is equal to the thickness of the film, so that the plastic melt flowing out of the die lip is extruded onto the fiber tape 13 . For example, by controlling the extrusion amount of the melt in the extrusion die and the running speed of the heating roller 1, the thickness of the melt film is controlled at 80-150 microns, preferably 100 microns, and the distance betwee...

Embodiment 3

[0050] In the following embodiments, the average value of the retroreflection coefficient of the annular mold belt 8 surface at an observation angle of 0.2° and an incident angle of -4° is 830mcd / lx / m2, and the maximum value of the retroreflection coefficient is 920mcd / lx / m2, and the retroreflection coefficient is the largest The value is 750mcd / lx / m2.

[0051] (1) according to the scheme of embodiment 2, be that 22 / g (10min) anti-ultraviolet grade polycarbonate resin is pressed into thickness by extrusion molding by the scheme of embodiment 2 and be 150 microns, width is the resin film of 1.25 meters band microprism forming layer , compounded with BOPET film at the pressing point C, the polyester film plays a role of polishing and protection, and can be finally peeled off. The obtained reflective film was measured at 20 points, and the retroreflection coefficient was tested by a retroreflection coefficient detector with an observation angle of 0.2° and an incident angle of -4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com