Processing method and detecting device for deflection of label paper at portion of zero setting device of high-speed packaging machine

A label paper and packaging machine technology, applied in the direction of packaging cigarettes, cigars, etc., can solve the problem of label paper misalignment, etc., achieve the effect of simple structure and reduced mean time to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

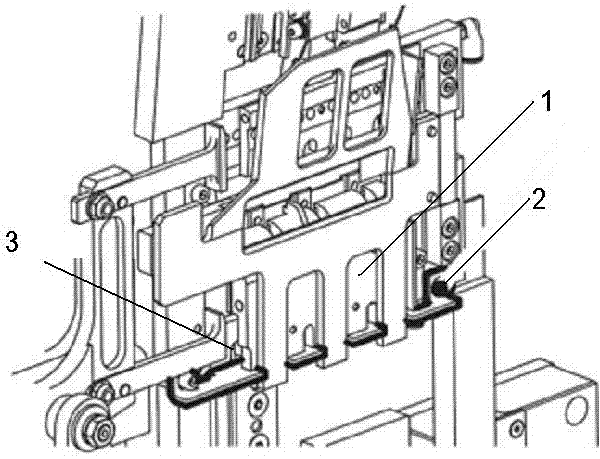

[0016] Such as figure 1 As shown, a high-speed packaging machine zero-setting device label paper out-of-position detection device includes: GDX6S host, zero-setting device 1, optical fiber out-of-position detector 1, optical fiber out-of-position detector 2 and optical fiber out-of-position detector 2 3, and two optical fiber out-of-position detectors The device is installed on both sides of the zero setter 1.

[0017] In order to better play the role of the detector, the optimal installation position of the detector is: fiber misalignment detector-2 is 3mm away from the inner baffle of zero-setter 1, and 2mm away from the bottom baffle of zero-setter 1; Detector 2 3 is 3mm away from the bottom baffle of zeroer 1, and the distance between the two optical fiber misalignment detectors is 104mm.

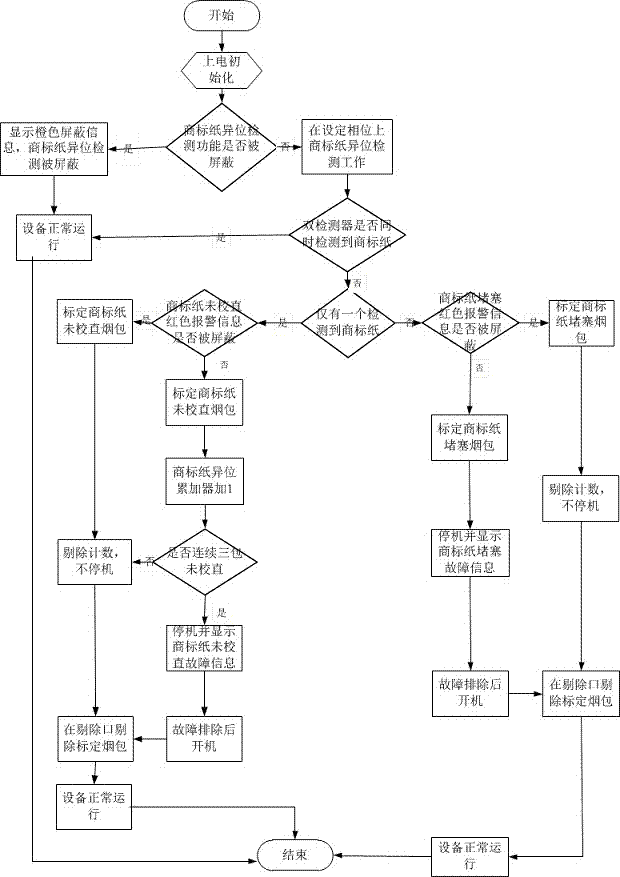

[0018] Such as figure 2 As shown, a GDX6S high-speed packaging machine zero-setting device label paper out-of-position detection method includes the following steps:

[0019] (1) In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com