Packing machine capable of conveying multiple materials

A packaging machine and multi-material technology, applied in the direction of packaging, can solve the problems of increasing the workload of workers, failing to meet production needs, and waste of manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

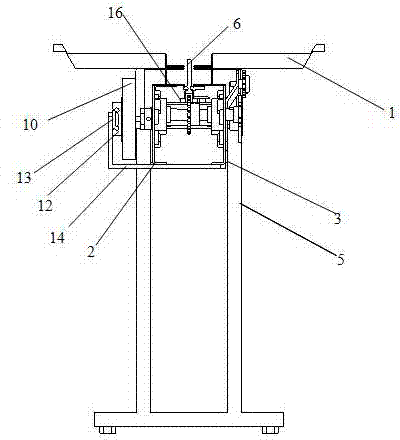

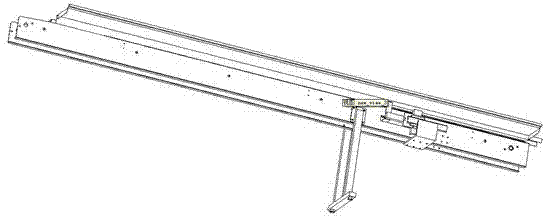

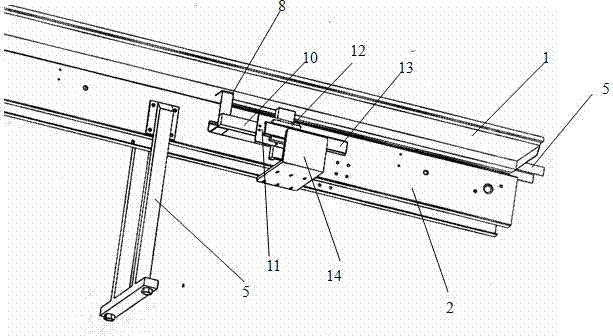

[0012] A packaging machine capable of transporting multiple materials, including a workbench 1, a side plate, and a guide rail assembly. The workbench 1 is divided into a left workbench and a right workbench, and the side plate is divided into a left side plate 2 and a right side plate 3, and guide rails The assembly includes a guide rail A4 and a guide rail B. The guide rail A4 is divided into a left guide rail and a right guide rail. The left and right guide rails are respectively installed on the left and right side panels. ; The pitch fork 6 is divided into a pitch fork A and a pitch fork B, and the pitch fork A and the pitch fork B are kept on a straight line longitudinally; the left and right workbenches are symmetrically installed on On the left and right guide rails; there is a pumping plate under the workbench, and the pumping plate is divided into a pumping plate A7 and a pumping plate B8, which are respectively installed under the left and right workbenches; the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com