Device and method used for separating and conveying harness wires

A technology of heald and separation mechanism, which is used in transportation and packaging, stacking of objects, de-stacking of objects, etc., can solve the problem of difficulty in ensuring reliability, high control difficulty, and difficulty in improving the speed and efficiency of separation and conveying of healds, etc. problem, to achieve the effect of fast speed, low control difficulty and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

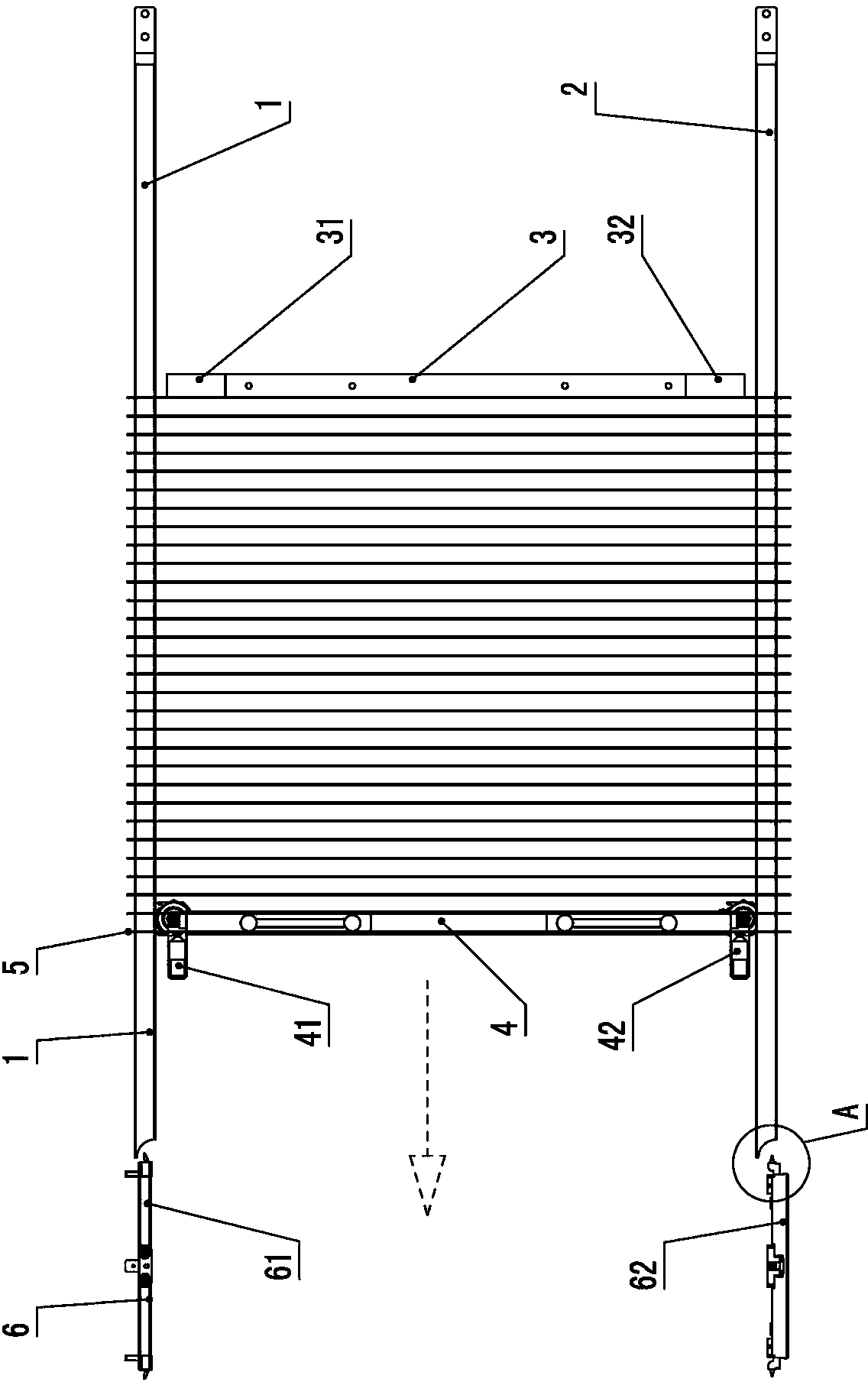

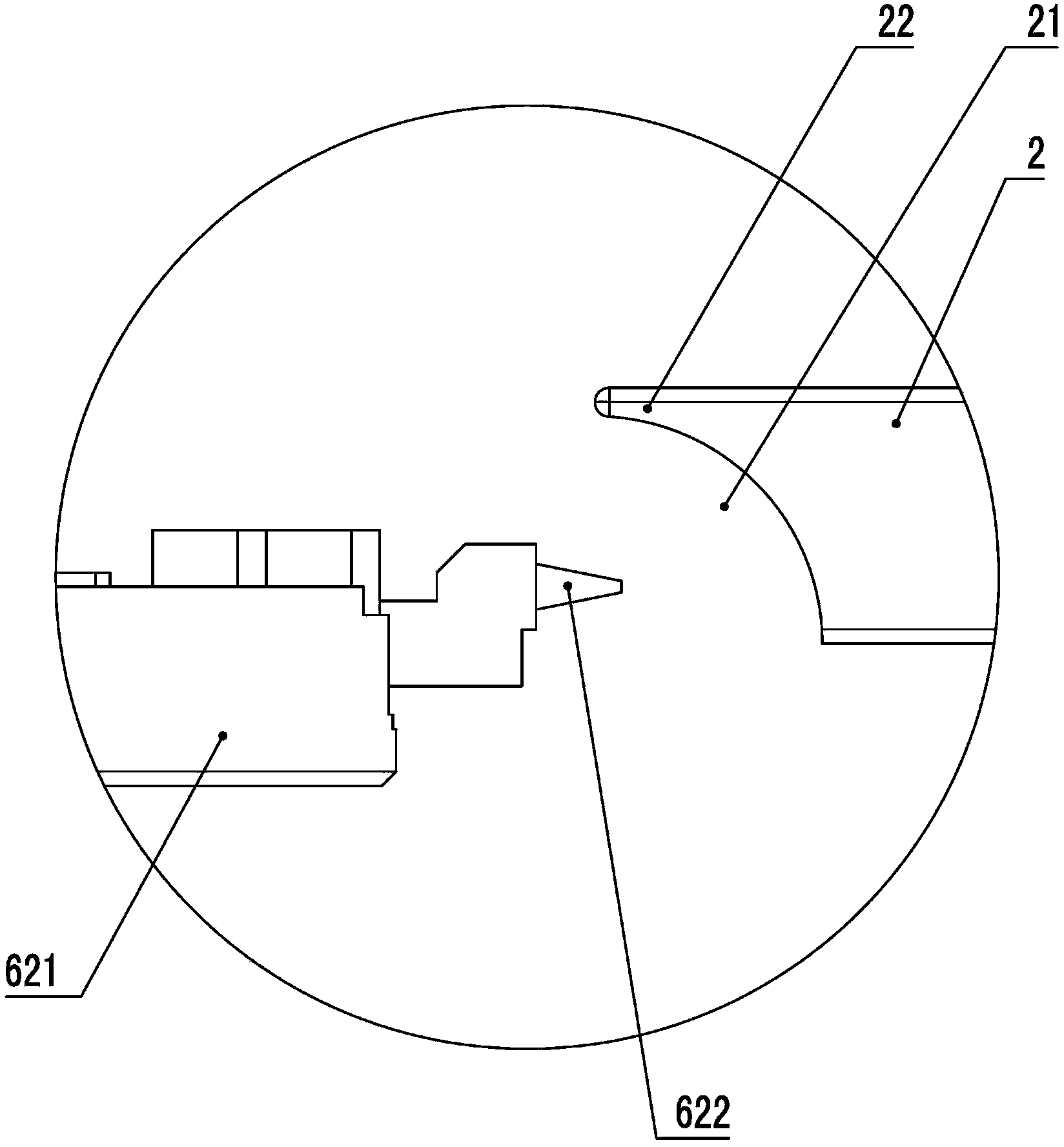

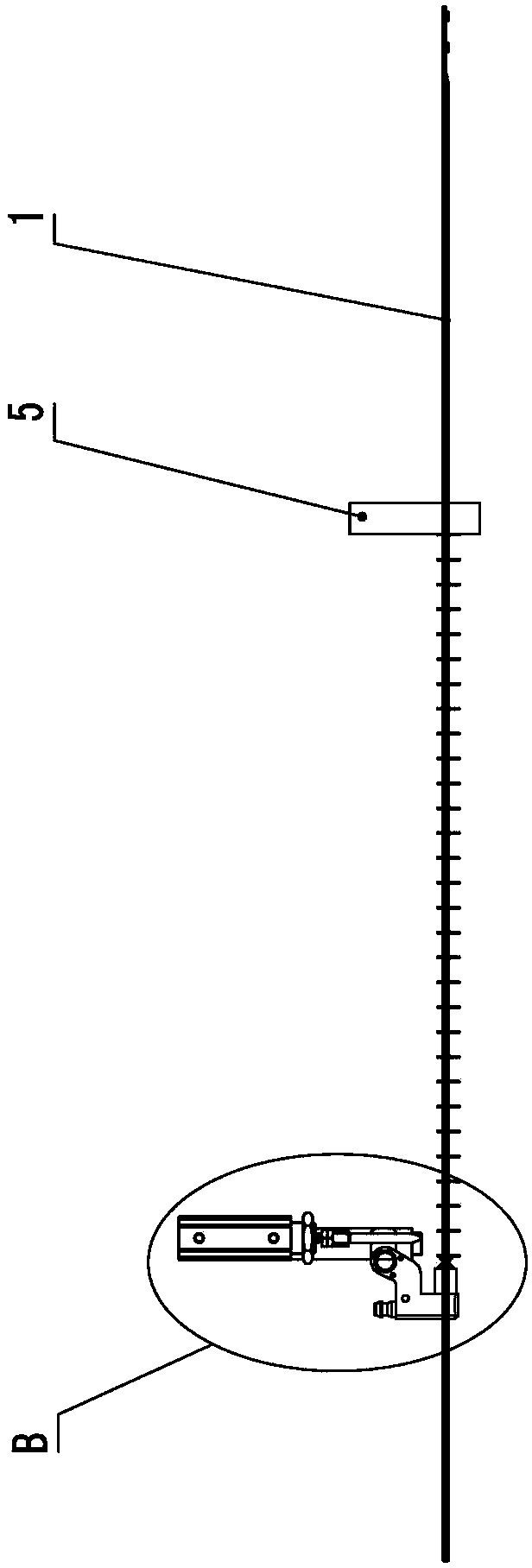

[0038] Figure 1 to Figure 9 The reference numerals in are: upper stringer 1; lower stringer 2; lower arc avoidance gap 21; lower pointed head 22; pusher mechanism 3; Upper separation mechanism 41; Upper cylinder 411; Upper push rod 412; Upper rotating shaft 413; Upper rotating arm 414; Upper suction cup 415; Upper limit buffer block 416; Lower separation mechanism 42; Connecting rod 43; Heald element 5; Upper perforation 51; lower perforation 52; heald eye 53; lead wire mechanism 6; upper receiving device 61; lower receiving device 62;

[0039] Such as Figure 1 to Figure 9 As shown, a device for separating and conveying healds, including a base, an upper stringer 1 passing through the upper hole 51 of the heald element 5, and a lower stringing rod 2 passing through the lower hole 52 of the heald element 5 , the pushing mechanism 3 that pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com