Electromagnetic brake with air pressure damping structure

A technology of electromagnetic brake and damping structure, which is applied in the direction of hoisting device, etc., can solve the problems of complex structure, unsolved noise impact, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

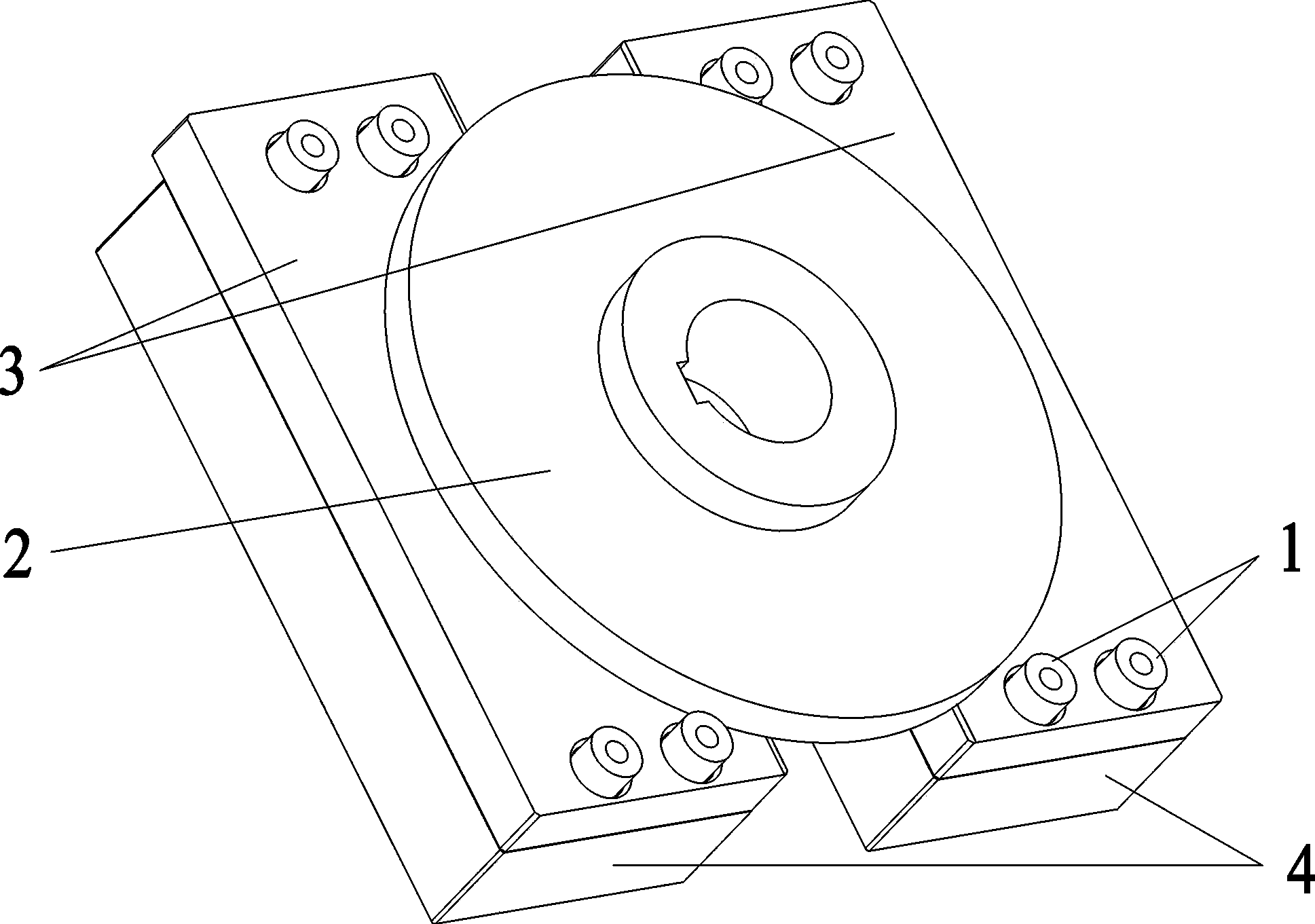

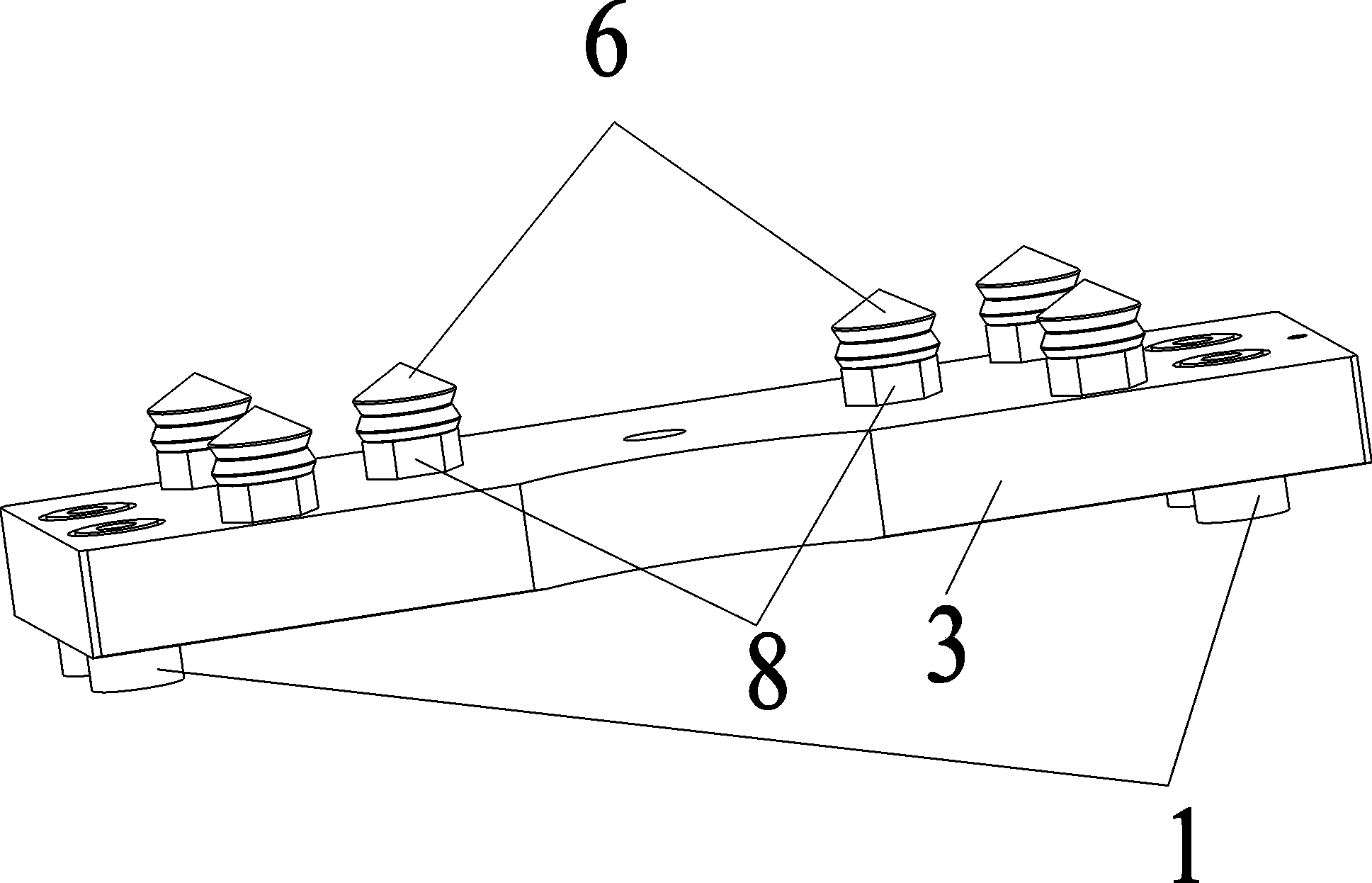

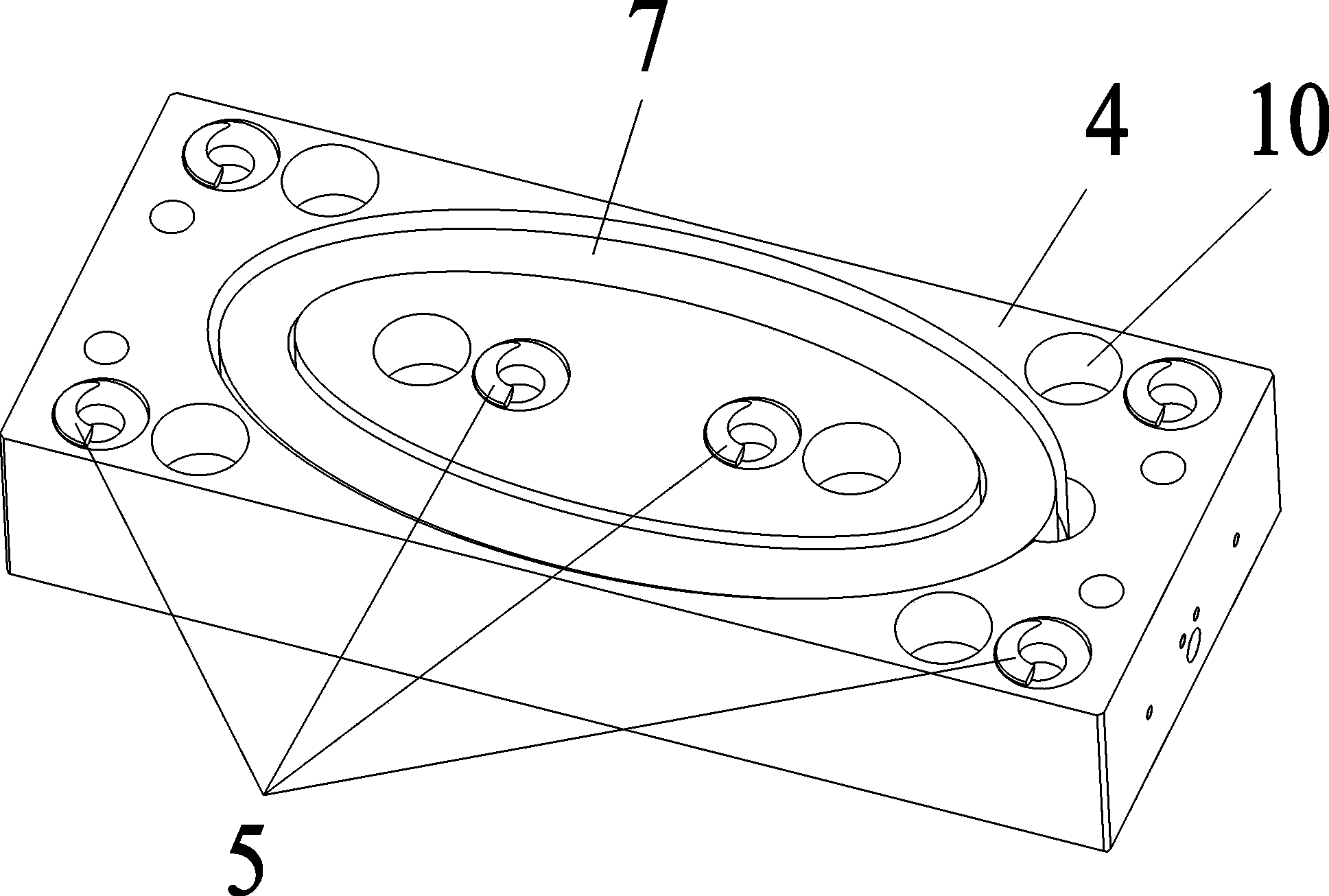

[0025] Such as Figure 1~6 Among them, an electromagnetic brake with a pneumatic damping structure, including an iron core 4 and an armature 3, is also provided with a friction plate 2 that forms a frictional fit with the armature 3, and a spring 5 that makes the armature 3 spring up is provided in the iron core 4, There is also a coil 7 that makes the armature 3 adsorb to the iron core 4. A plurality of plug cores 8 are arranged on the armature 3. The ends of the plug cores 8 are covered with rubber plugs 6. On the iron core 4, a plurality of plug cores 8 are provided. Blind hole 10 for mating plug core 8 .

[0026] Such as figure 1 Among them, the brake in this example is a normally closed brake, and the friction plate 2 is fixedly connected to the motor shaft. When the coil 7 is not energized, the spring 5 presses the armature 3 and the friction plate 2 tightly, and the motor cannot rotate. There is a gap of 0.4-0.8 mm between the armature 3 and the iron core 4, preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com