High-temperature lubricating grease and preparation method thereof

A lubricating grease and high-temperature technology, which is applied in the field of high-temperature lubricating grease and its preparation, can solve the problems that lubricating grease cannot meet the needs of special machinery, and achieve the effects of excellent extreme pressure and air wear resistance, excellent high-temperature performance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

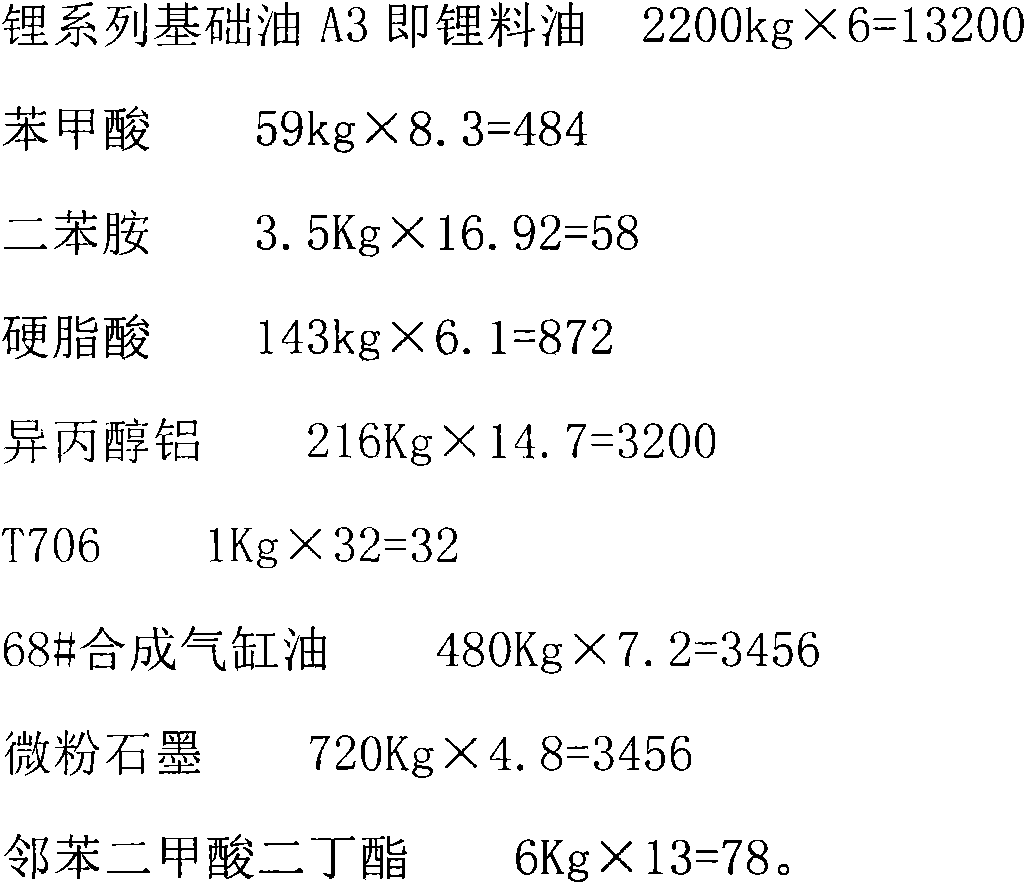

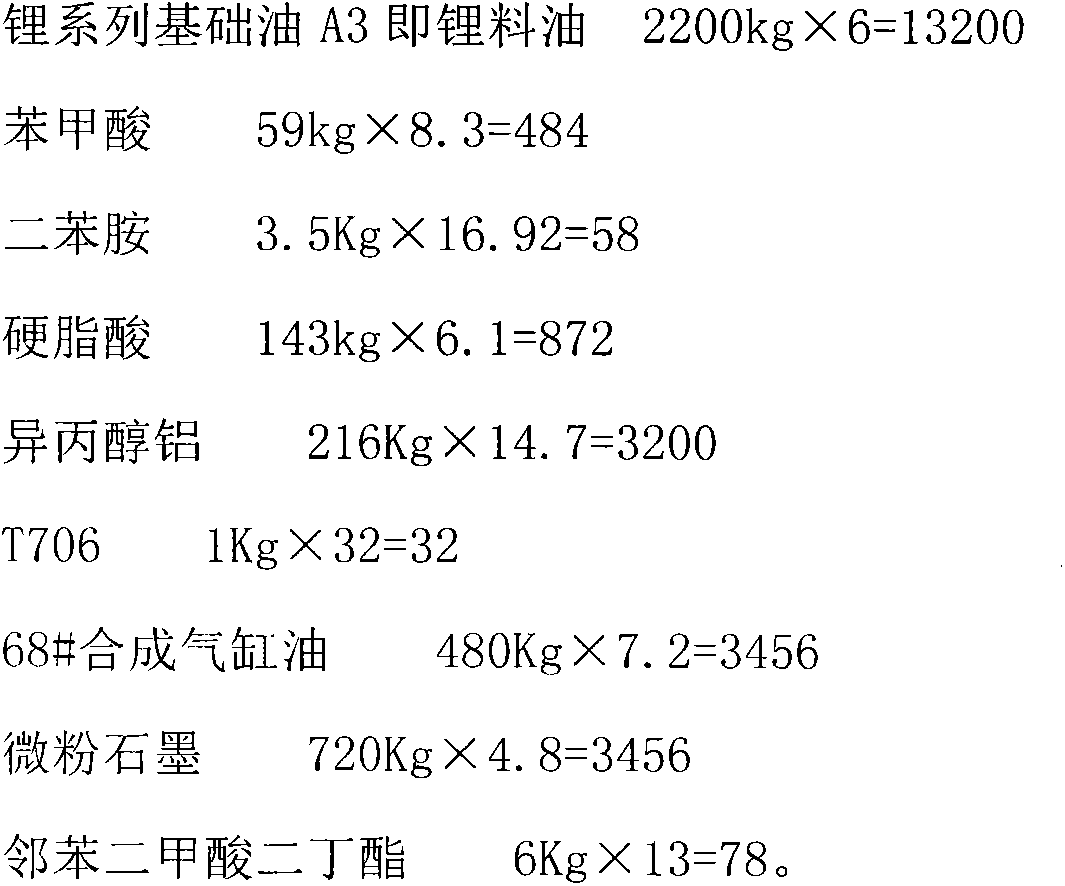

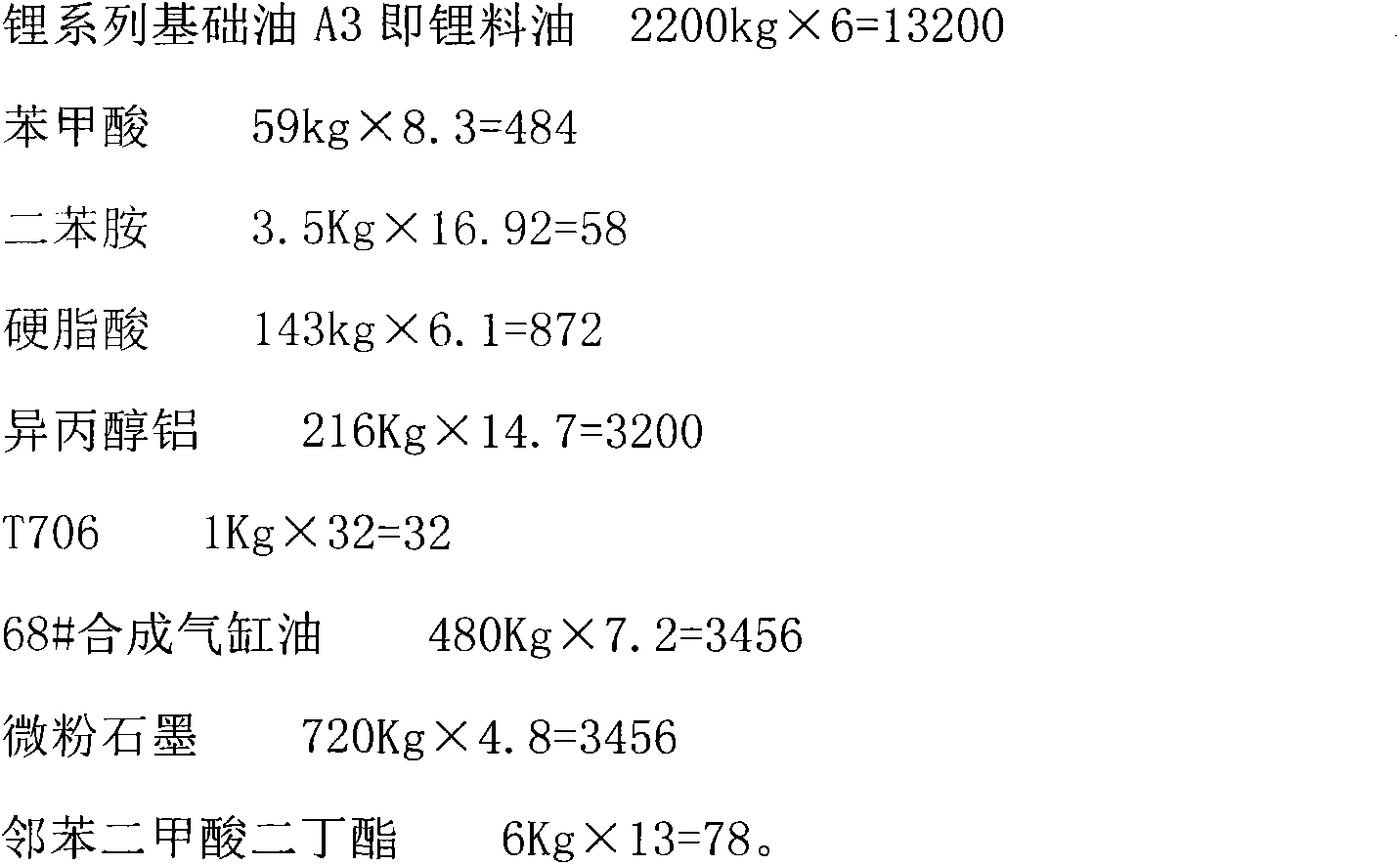

[0017] The present invention is made from following raw materials:

[0018]

[0019] Preparation:

[0020] The first step is to feed the material, close the bottom cut-off door of the refining kettle, put in 600Kg of autoclave melting oil (lithium series base oil A3 is lithium material oil), open the lower wing, stir the inner and outer wings at 45-50Hz, and the temperature rises to 60°C , drop into benzoic acid 59kg, temperature rises to 75-80 ℃, stop gas, keep stirring at constant temperature for 30 minutes, until benzoic acid dissolves. Add 143kg of stearic acid and 300Kg of warm oil (lithium series base oil A3 is lithium material oil), 108Kg of aluminum isopropoxide, stir for 15 minutes and add 108Kg of aluminum isopropoxide for a second time.

[0021] In the second step of replacement reaction, the temperature is raised to 125-130°C, 40-45Kg of pure water is added for replacement, and the mixture is stirred for 20-30 minutes. Continue to heat up (slowly heat up to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com