An ultra-high pressure water jet airport runway glue removal and marking execution device

A technology for airport runways and actuators, applied to roads, roads, road repairs, etc., can solve the problems of non-adjustable width range, inconvenient actual use, poor flexibility, etc., to achieve the function of reciprocating motion, fast and stable reciprocating motion, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

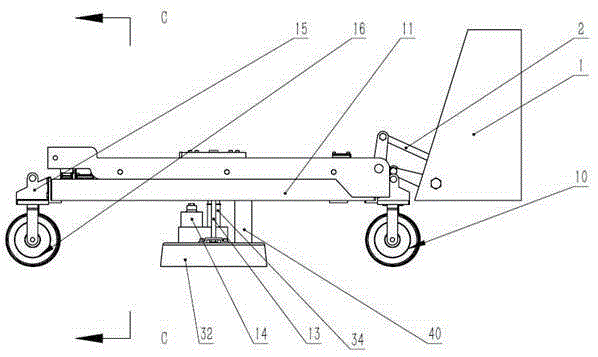

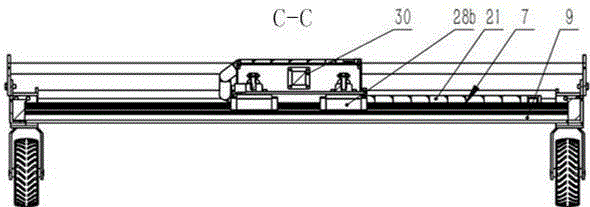

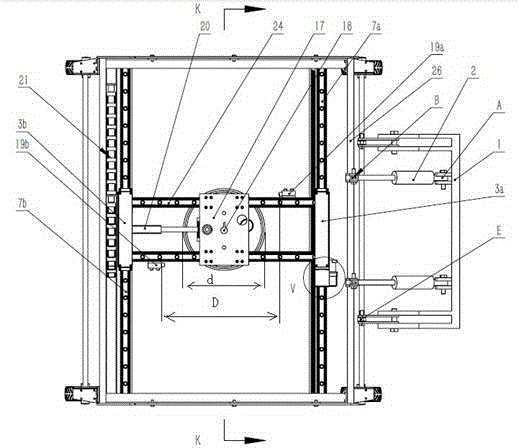

[0037] Embodiment 1: An ultra-high pressure water jet airport runway glue removal and marking executive device provided by the present invention is characterized in that it includes a control center, a traveling mechanism, a cleaning vehicle and an ultra-high pressure water jet plane cleaning device, wherein the traveling mechanism and The cleaning car is connected, and the control center is arranged on the cleaning car; two X-direction support beams 9 are provided on the walking mechanism, for example, figure 1 and Figure 4 In the middle are two relatively parallel X-direction support beams 9 . A first guide rail 7a and a first slide block 28a are arranged on the X-direction support beam 9 close to the cleaning vehicle, and a second guide rail 7b and a second slide block 28b are provided on the X-direction support beam 9 away from the cleaning vehicle, for example, figure 1 and Figure 4 There is one first guide rail 7a and one second guide rail 7b, and two first sliders 2...

Embodiment 2

[0049] Embodiment 2: The ultra-high pressure water jet airport runway deglue removal and marking execution device includes a folding mechanism, and the folding mechanism includes one or more hydraulic cylinders 2 and connecting frames 1 connected to the control center. The hydraulic cylinder 2 It is connected with the connecting frame 1 through a rotating pair, and the end of the piston rod of the hydraulic cylinder 2 is connected with the horizontal connecting rod 26 through a rotating pair, and the horizontal connecting rod 26 is arranged on the traveling mechanism, for example, figure 1 Among them, the horizontal connecting rod 26 is arranged on the supporting frame 38 of the traveling mechanism, and the connecting frame 1 is connected with the cleaning vehicle. When the cleaning task is finished or the cleaning vehicle is moving towards the marking line in other areas, in the existing technology, the cleaning vehicle can only move slowly, which prolongs the working time. A...

Embodiment 3

[0050] Embodiment 3: The ultra-high pressure water jet plane cleaning device described in Embodiment 2 also includes a lifting mechanism 13 driven by a screw. like figure 1 , figure 2 , Figure 5 and Figure 7 As shown, the lifting mechanism 13 includes a base 17, two lead screws 13, two screw nuts 35, two small spur gears 36, a large spur gear 37, a rotary dial 18, and a gear support frame 38. Two leading screws 13 are positioned between the base 17 and the plane cleaner 12, the upper end of the leading screw 13 passes through two through holes of the base 17, the lower end of the leading screw 13 is connected with the plane cleaner 12, and the upper end of the leading screw 13 is connected with two A screw nut 35, the two small spur gears 36 are fixed on the outer rings of the two screw nuts 35, the large spur gear 36 is located in the middle of the two small spur gears 36 and meshes with the small spur gear 36, the gears The support frame 38 is connected to the base 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com