Silting reduction system for heavily silt-carrying river reservoir

A technology for rivers and reservoirs, which is applied in general water conservancy projects and the engineering field of reducing sedimentation in sandy rivers and reservoirs, can solve the problems of reducing the amount of sediment, waste of resources, and no reservoir dredging, etc., so as to improve the effect of sediment removal and ensure long-term maintenance. , the effect of expanding the scope of traceability and scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

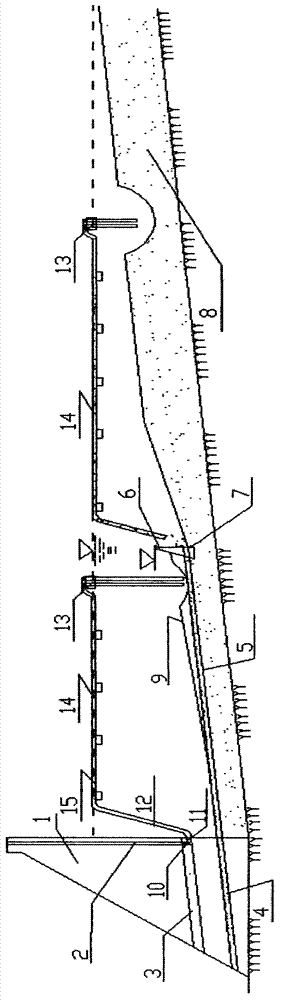

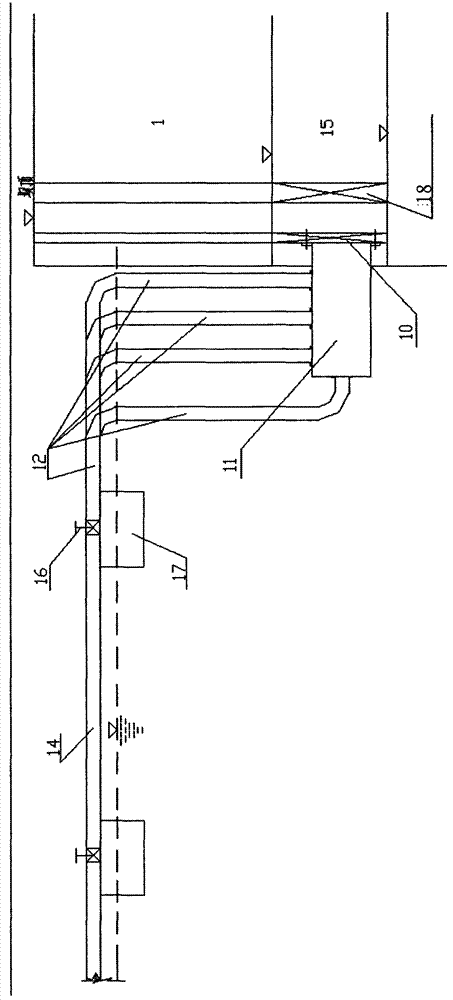

[0011] Combine below figure 1 and figure 2 , the silt reduction system of the sandy river reservoir of the present invention is described in detail.

[0012] A sediment-retaining submerged dam 6 is built upstream of the dam 1 to divide the reservoir into front and rear parts, wherein, between the dam 1 and the sediment-retaining submerged dam 6 is a clear reservoir area, and the upstream of the sediment-retaining submerged dam 6 is a muddy reservoir area. The position and crest elevation of the sediment-retaining submerged dam 6 can be calculated by those skilled in the art according to the existing technology and design specifications according to the water level of the dam, the conditions of water and sediment entering the reservoir, the geology and shape of the riverbed in the reservoir area, etc. OK, no more details here. Set sand inlet flow channel 7 on described sand-holding submerged dam 6, control gate is set at described sand-entry flow channel 7 front ends, pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com