Brush electronic fan drive protection system and self-diagnosis method

An electronic fan, drive protection technology, applied in engine components, machines/engines, engine cooling, etc., can solve problems such as inconvenient operation, poor heat dissipation, and inability to achieve intelligent self-fault diagnosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

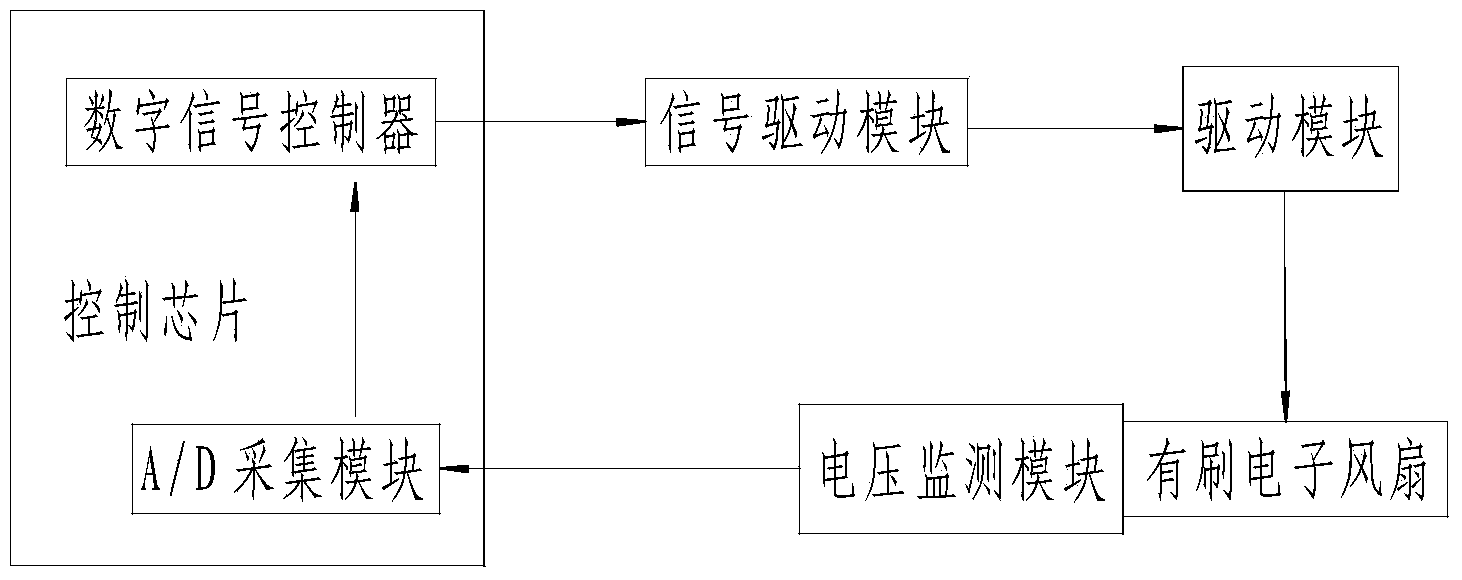

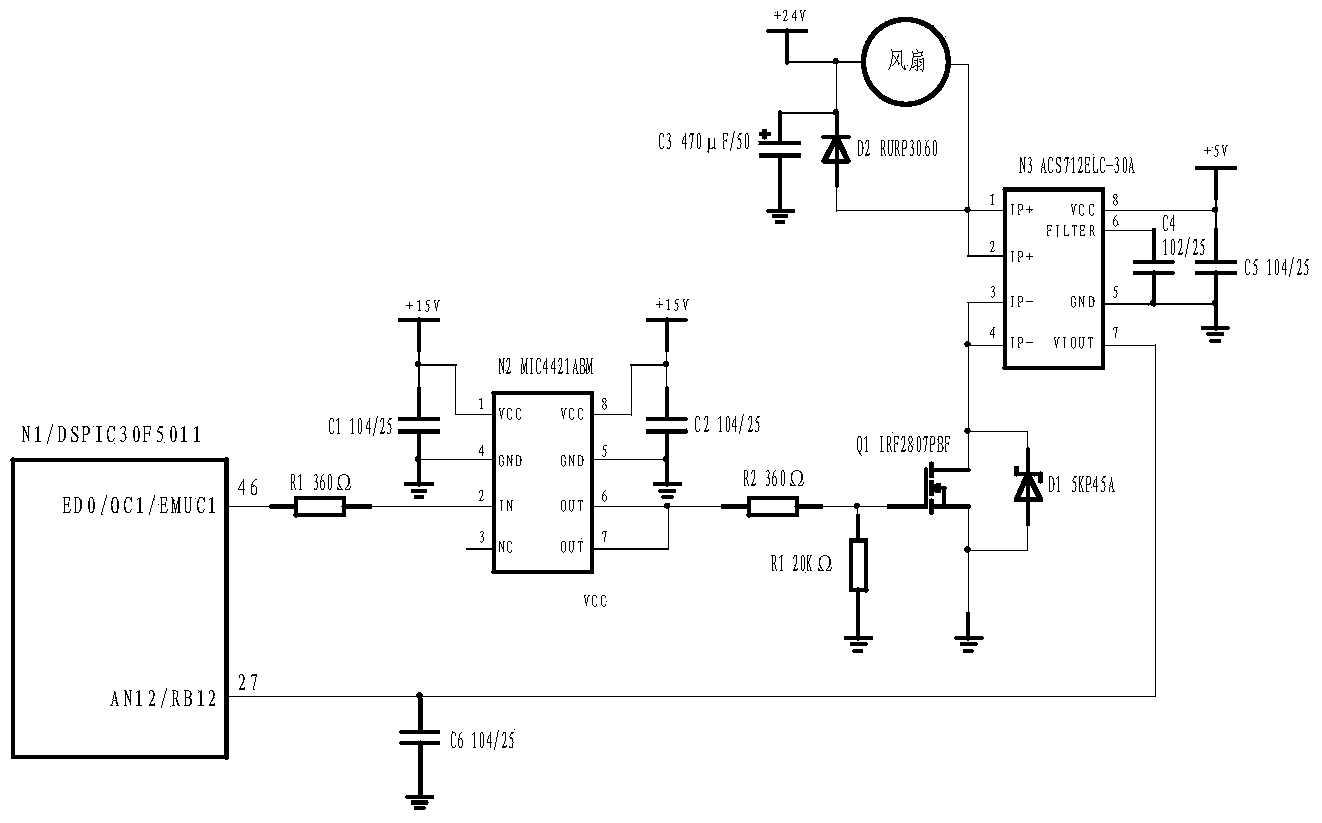

[0028] A signal drive module is set between the control chip and the drive module, lines are set between the signal drive module and the control chip and the drive module, a brushed electronic fan is set between the drive module and the voltage monitoring module, and a brushed electronic fan is set between the drive module and the brushed electronic fan. The circuit is set; an A / D acquisition module and a digital signal controller are set in the control chip, an A / D acquisition channel is set between the A / D acquisition module and the digital signal controller, and an A / D acquisition channel is set between the A / D acquisition module and the voltage monitoring module A line is set between the digital signal controller and a signal driving module.

Embodiment 2

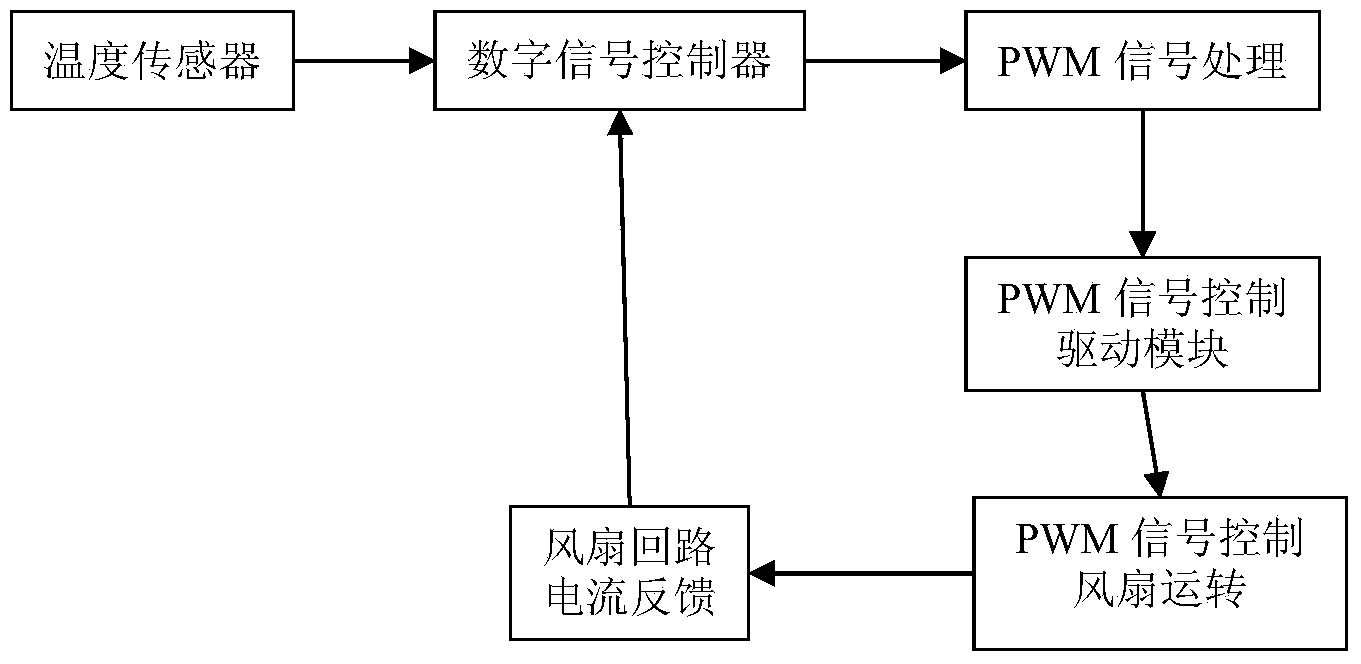

[0030] The system program is initialized, and then the alarm is checked. If there is any abnormality, it will enter the alarm processing program. If there is no abnormality, continue. According to the temperature of the engine water tank detected by the temperature sensor, set the temperature of the engine water tank when the fan is started. When the temperature value T of the engine water tank detected by the temperature sensor is less than the opening temperature, the single cycle of the output code ends. When T>=the opening temperature, the fan is started according to the preset; after the temperature sensor converts the temperature of the engine water tank into a digital signal, It is transmitted to the digital signal controller, compared and calculated according to the software setting value, and a PWM signal is generated according to the position where the fan needs to be turned on and the required speed. When the PWM control signal is 0, the drive module is turned off, an...

Embodiment 3

[0032] The fan disconnection diagnostic program is as follows: when the PWM control signal is greater than or equal to X, X is set to a value between 10% and 100% according to the specific system, and the current monitoring module detects that V2 is less than or equal to V0+A, and A is the setting Error, after the digital signal controller detects the same signal PWM>=X and V2<=V0+A for many times, it will immediately send an alarm signal to realize the fan circuit breaker diagnosis; when the PWM control signal is less than X, or V2 is greater than V0+A , the output code single cycle ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com