Floating ball self-sucking valve with lever structure and design method thereof

A self-priming valve, floating ball technology, applied in the direction of the float, valve details, valve device and other directions of the control valve, can solve the problems of poor cavitation performance, poor sealing, low pump efficiency, etc., to improve performance and operational reliability, The effect of improving service life and reducing leakage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

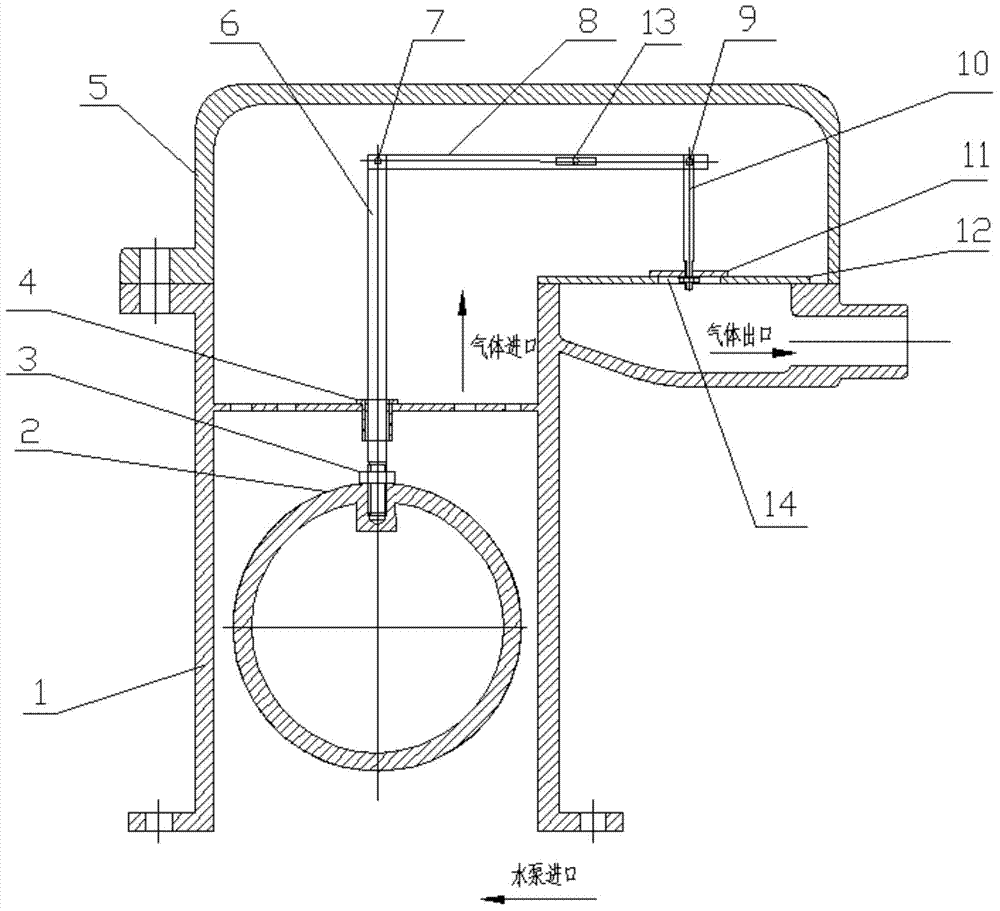

[0034] Such as figure 1 As shown, the floating ball self-priming valve with lever structure according to the present invention includes a valve body 1 and a hollow floating ball 2. The valve body 1 is provided with an air outlet perpendicular to it, and the upper opening of the air outlet, And be provided with an air valve port cover 12; The hollow floating ball 2 is connected with one end of the ejector rod 6 through the floating ball fastening nut 3, and the ejector rod 6 passes through the ejector rod movable pipe 4 fixed on the valve body 1, The other end of the ejector rod 6 is connected with the valve rod 10 through a lever 8 , and the lever fulcrum 13 of the lever 8 is fixed on the side wall of the valve body cover 5 . The ratio of the length of the power arm of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com