Low-abrasion slurry pipeline conveying system and method

A pipeline transportation and low-wear technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of worn pipe wall, long transportation distance, corroded transportation pipeline, etc., to reduce transportation friction and improve use Longevity and the effect of reducing the risk of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

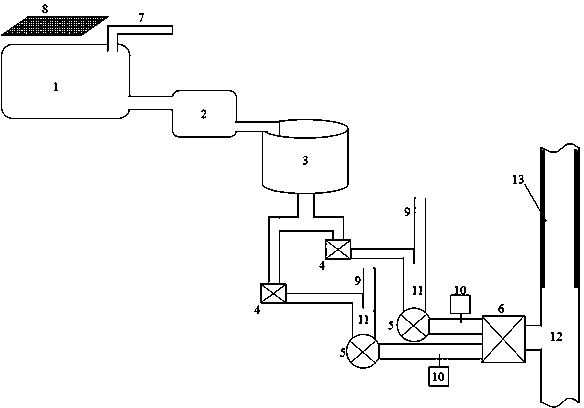

[0025] as attached figure 1 As shown, the long-distance slurry pipeline transportation system that effectively reduces pipe wall wear in the present invention includes three parts as a whole, namely the milk of lime preparation subsystem, the milk of lime pumping addition subsystem and the slurry transportation subsystem. The milk of lime preparation subsystem is used to prepare milk of lime with a specific concentration, the milk of lime pumping and adding subsystem is used to mix and add a predetermined amount of milk of lime into the conveying slurry, and the slurry conveying subsystem uses It is used to transport the slurry added with lime milk. The important innova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com