Method for determining precious metal in platinum-palladium ores

A technology of precious metals and platinum group metals, applied in the chemical field, can solve problems such as cumbersome processes, low efficiency, and inapplicability of platinum group metals, and achieve the effects of improving work efficiency, reducing detection costs, and high accuracy of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

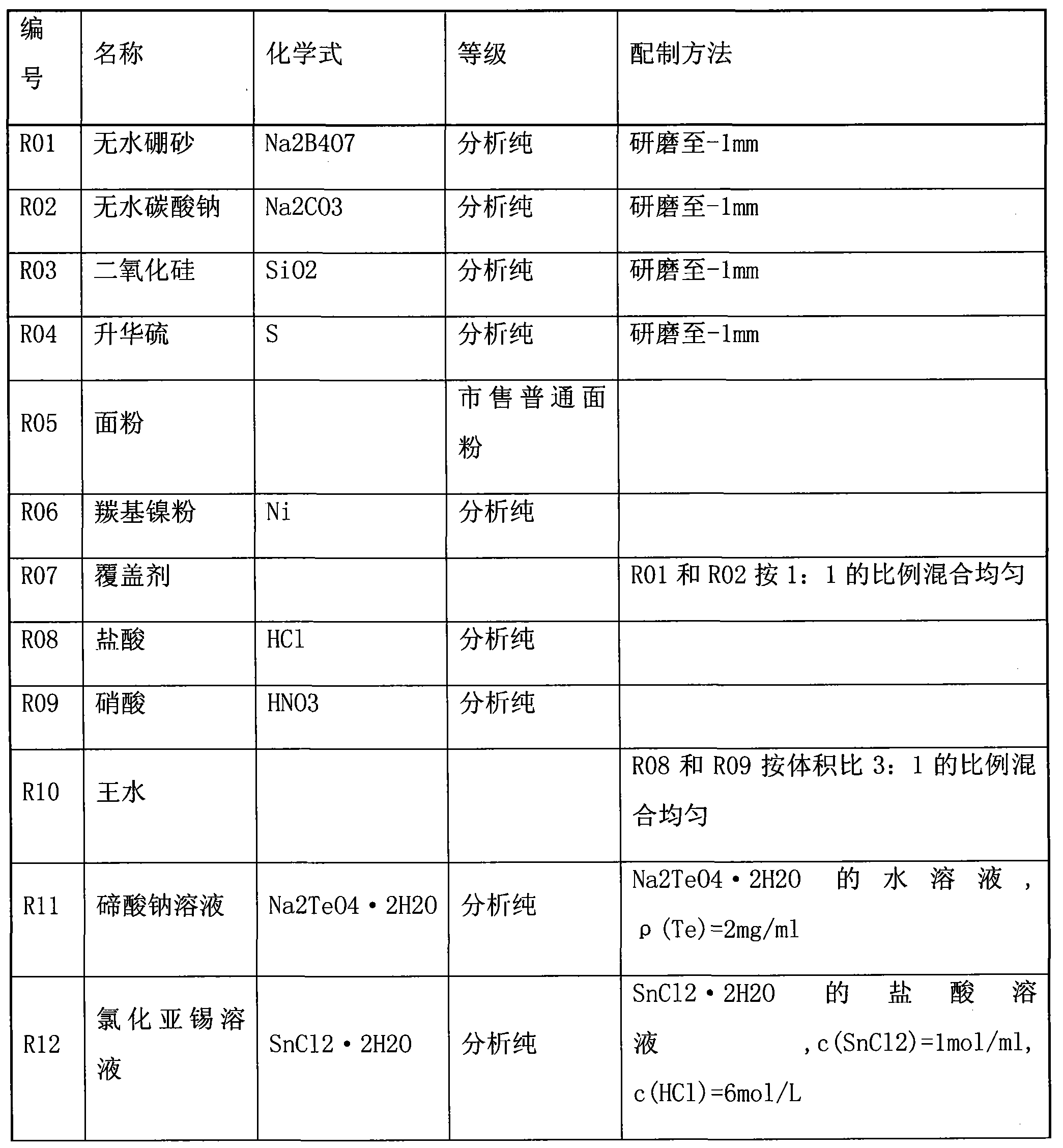

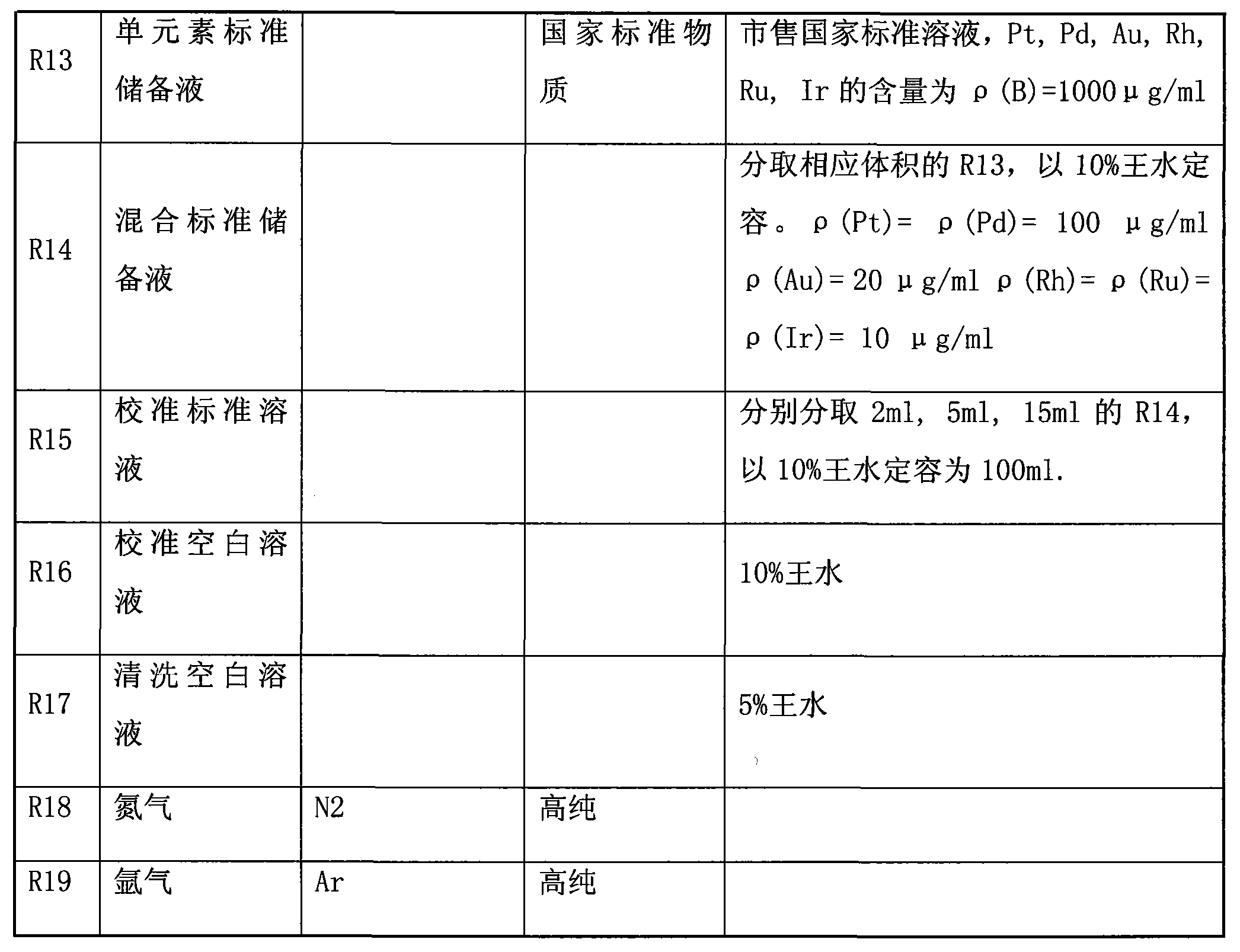

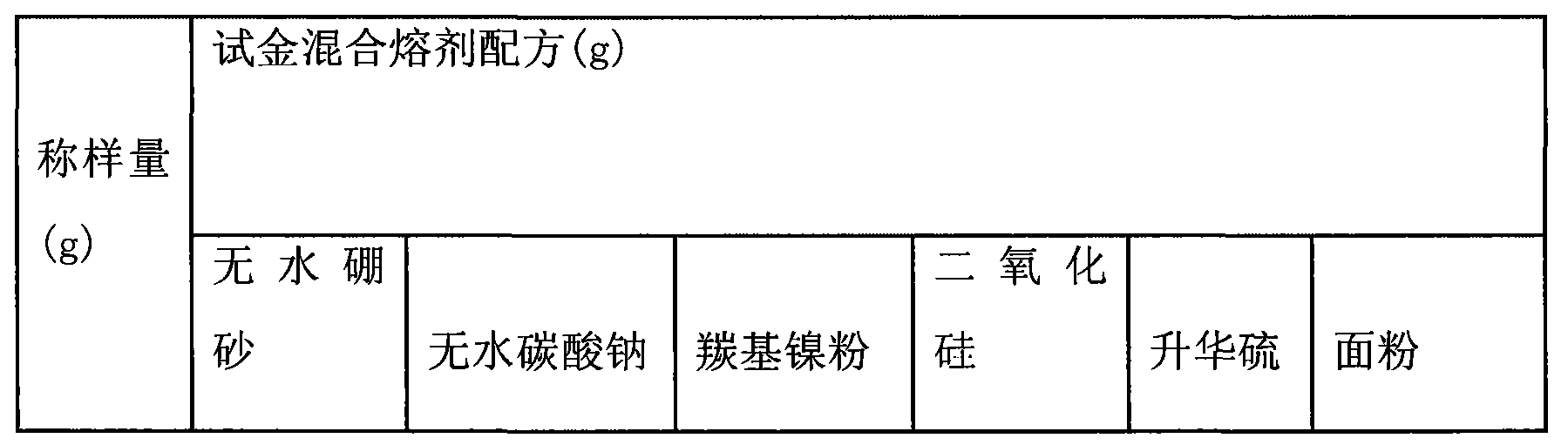

Method used

Image

Examples

Embodiment Construction

[0059] A method for measuring precious metals in platinum group metal ores comprises the following steps:

[0060] (1) obtain the nickel matte button from the noble metal in the nickel matte assay gold enrichment sample;

[0061] (2) pulverize the nickel matte button with a grinder;

[0062] (3) adding the pulverized nickel matte into the hydrochloric acid solution, heating and dissolving to remove the base metal and sulfur in the nickel matte;

[0063] (4) adding reducing agent and co-precipitating agent to recover a small amount of precious metal lost in solution in step (3) gained solution;

[0064] (5) Negative pressure suction filtration obtains the precious metal precipitate;

[0065] (6) Dissolve the precipitate in step (5) together with the filter membrane with aqua regia in a water bath and dilute to constant volume with pure water;

[0066](7) draw the calibration curve of platinum, palladium, gold, rhodium, ruthenium, iridium with inductively coupled plasma atomi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com