Checking method based on vibration positioning GIS partial discharge equipment

A partial discharge and calibration technology, applied in the direction of measuring electrical variables, measuring devices, instruments, etc., can solve problems such as inability to respond quickly and lack of national standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below:

[0023] The present invention needs to complete operation according to the following steps:

[0024] Step 1: Cavity Preparation for Partial Discharge Generation

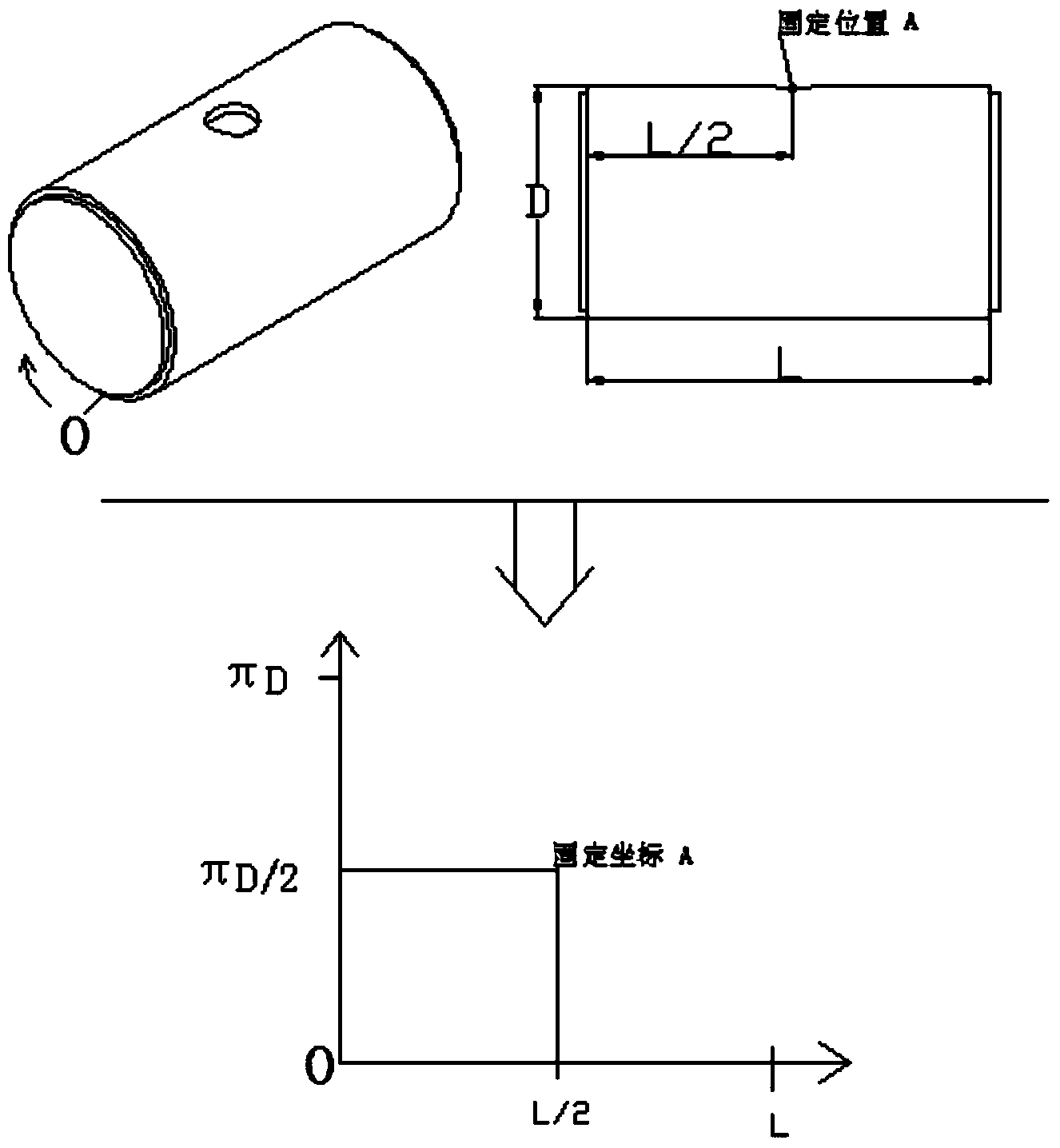

[0025] Make a two-dimensional plane of the cylindrical cavity used for checking by using the generation method, and set the coordinate system, as shown in the attached figure 1

[0026] Step 2: Standard Vibration Signal Generator Placement

[0027] The standard vibration signal generator is placed at the opening of the cylindrical cavity to simulate the vibration signal caused by the shock wave signal generated by the partial discharge. The coordinates of the vibration signal generator are fixed and marked in the developed coordinate system.

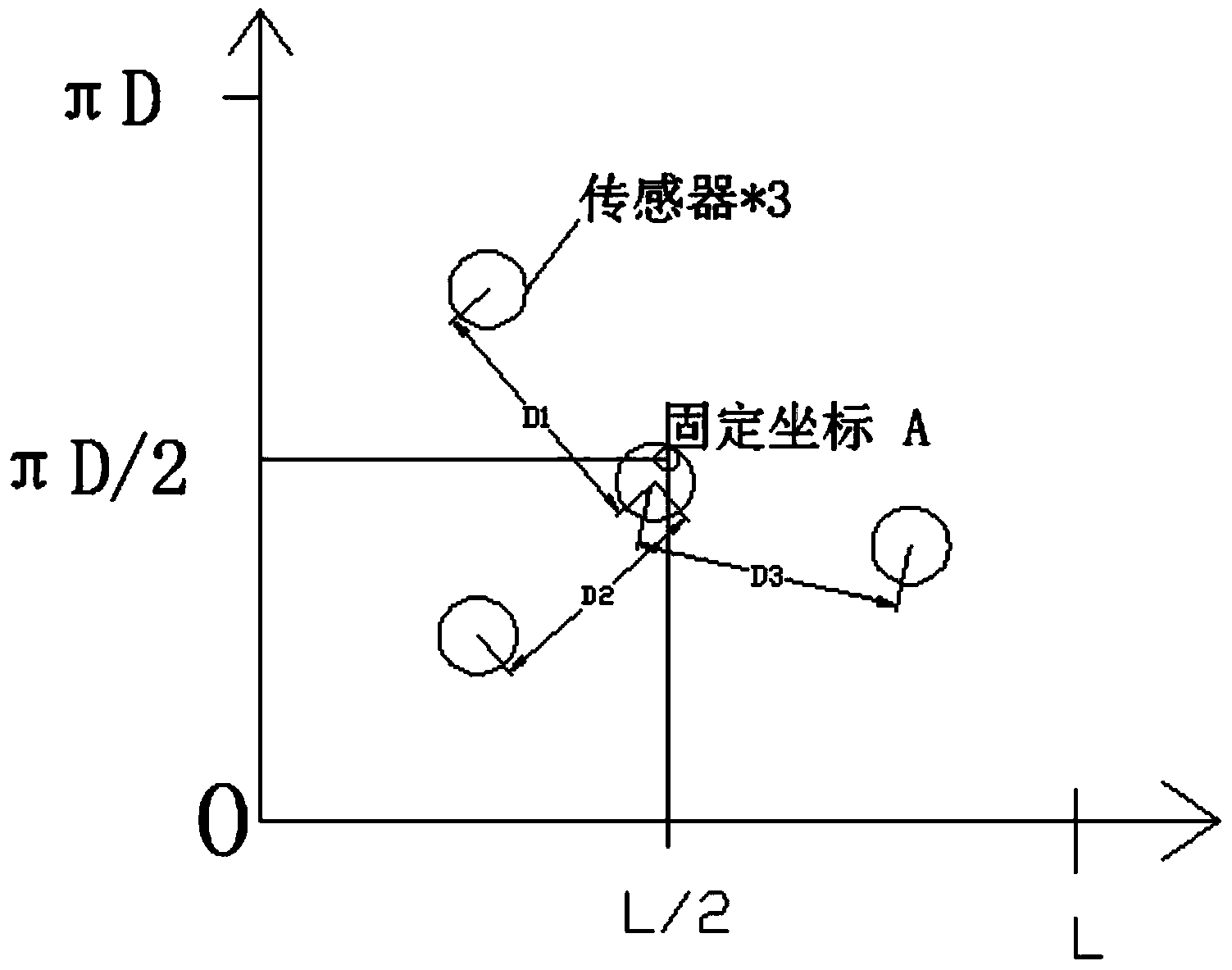

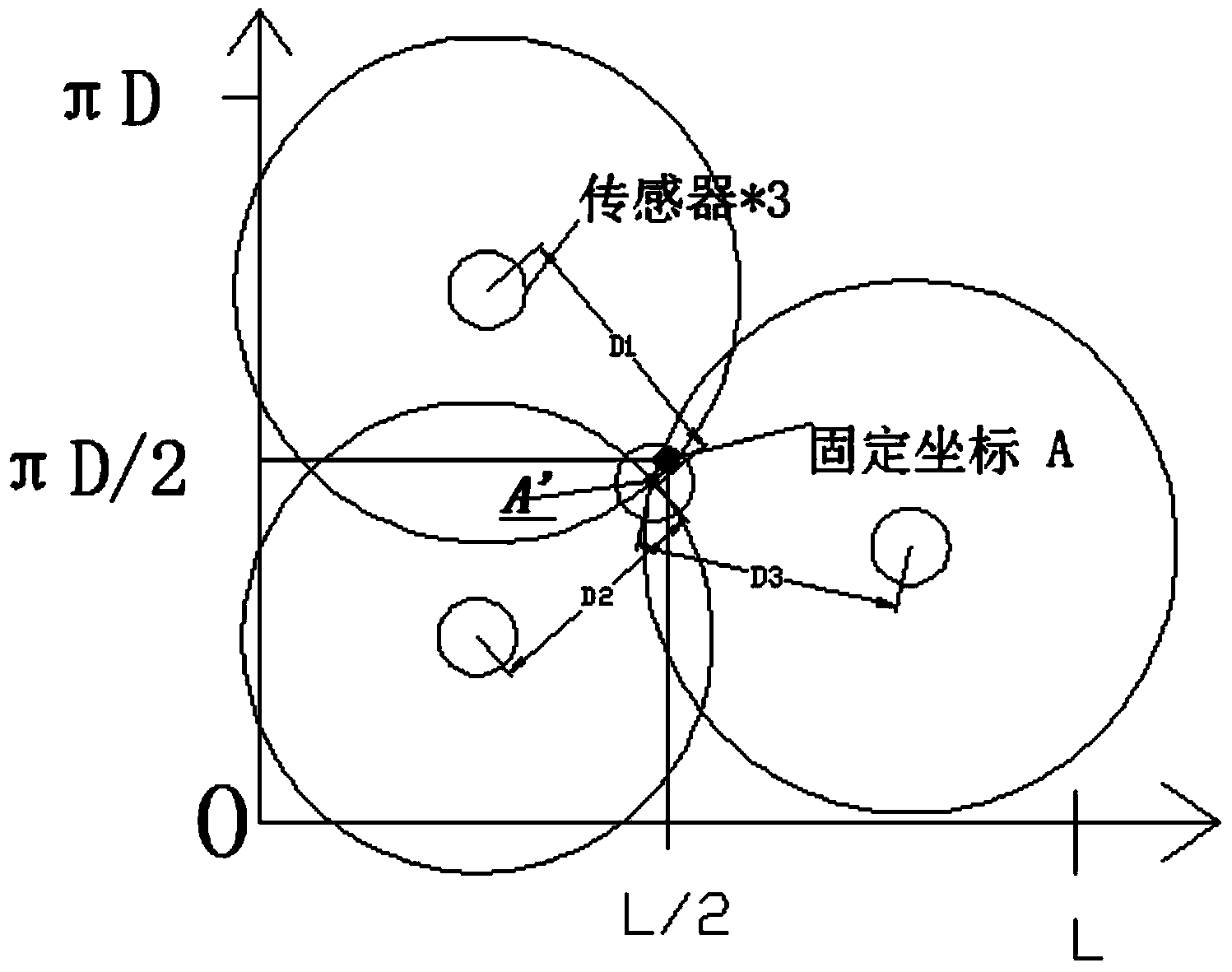

[0028] Step 3: Randomly attach the sensors of the GIS partial discharge detection equipment to be tested to the outer wall of the cylindrical cavity. figure 2 .

[0029] Step 4: Let the vibration signal generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com