Production of tripheny-stannic chloride

A technology of triphenyltin chloride and a new method, applied in the direction of tin organic compounds, etc., can solve the problems of large environmental impact, large amount of sodium salt, difficult handling and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] The raw materials used in the present invention are: metal magnesium, tetrahydrofuran, bromoethane, chlorobenzene, toluene, 120 # Mineral spirits, tin and chlorine.

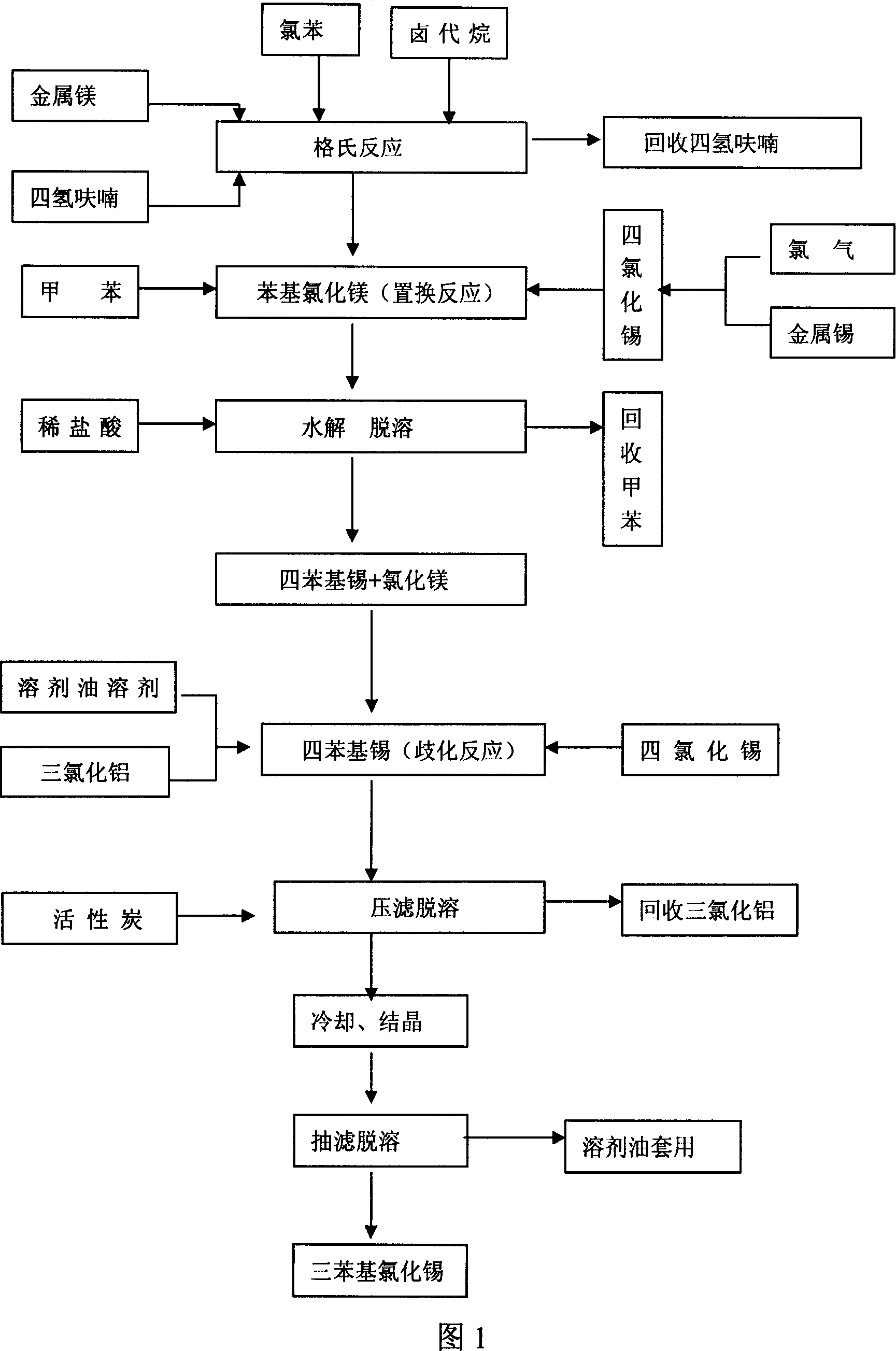

[0025] Concrete preparation steps are as follows:

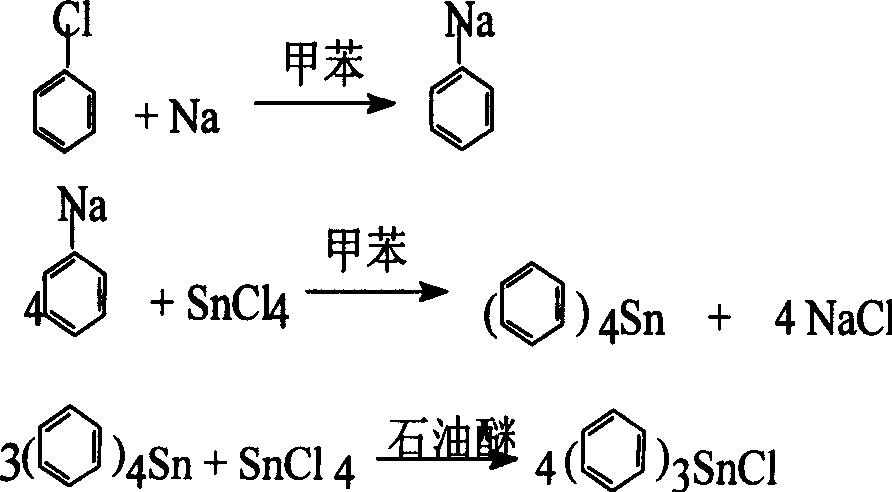

[0026] ①The preparation of tin tetrachloride is to react tin tetrachloride with metal tin and chlorine gas in a closed container; the temperature is controlled below 70°C;

[0027] ② In tetrahydrofuran solvent, chlorobenzene and metal magnesium undergo Grignard reaction, the temperature is controlled below 80°C, and the reaction is carried out for 5 to 6 hours to obtain phenylmagnesium chloride, using haloalkane as the initiator;

[0028] ⑧Put phenylmagnesium chloride in toluene solvent, slowly add tin tetrachloride dropwise to carry out displacement reaction, control the temperature at 20°C-30°C, raise the temperature to 95°C-105°C after dropping, keep the temperature for 4 hours, Get tetraphenyltin and by-product magnesium chloride;

[0029] ④ Dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com