Modeling and control method for color register system in electronic shaft gravure printing machine acceleration process

A system modeling and control method technology, applied in general parts of printing machinery, printing presses, adaptive control and other directions, can solve the problems of no mathematical model and few control methods in the color registration system, achieve good control performance, overcome inconsistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0040] Firstly, analyze the reasons for the color registration error in the acceleration process of the electronic axis gravure printing machine:

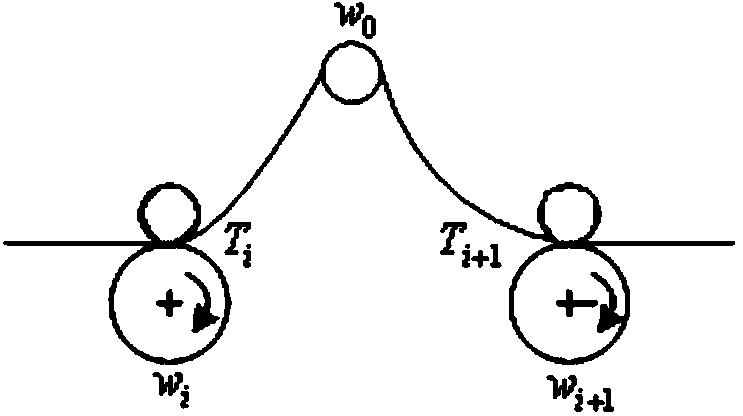

[0041] In order to facilitate the specific analysis of the cause of the color registration error during the acceleration process, we simplified the passive roller between two adjacent printing plate rollers to one, and then performed a qualitative analysis, such as figure 1 shown in figure 1 in, w i and w i+1 Indicates the angular velocity of two adjacent printing plate rollers, T i and T i+1 Respectively represent the discharge tension of plate i and the feed tension of plate i+1, w 0 (t) represents the angular velocity of the passive roller; make the following assu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com