Multi-axis motion control system and control method thereof

A multi-axis motion and control system technology, applied in the direction of digital control, electrical program control, etc., can solve the problem that a single communication channel cannot meet diversified needs, improve integration and flexibility, realize classified transmission, and data exchange reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

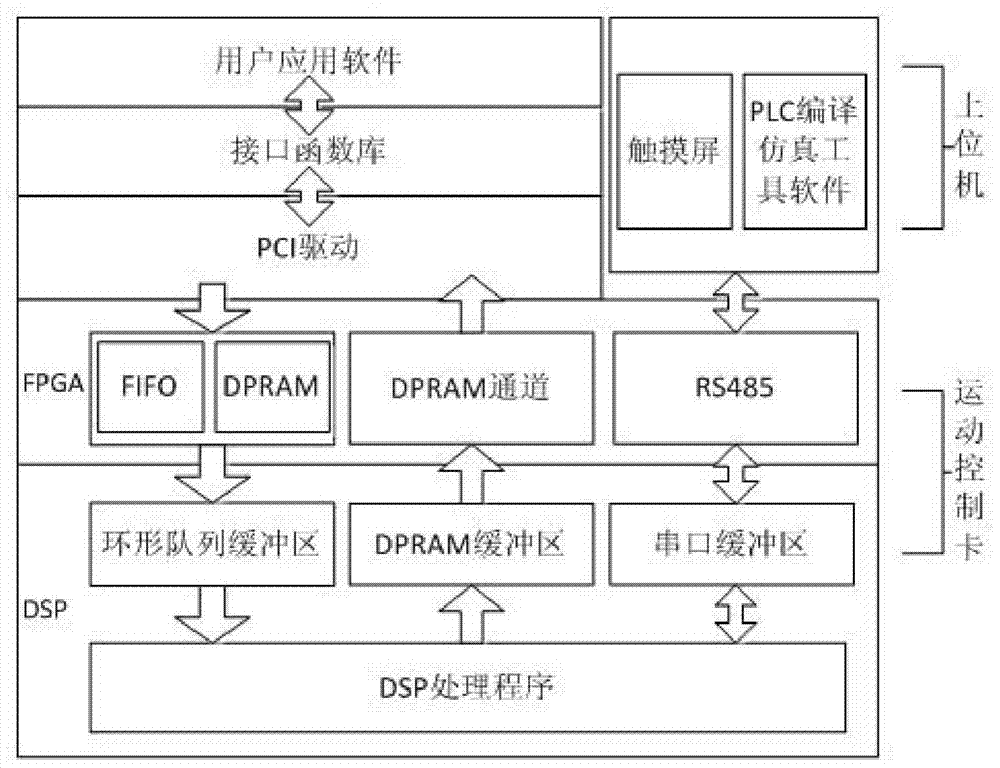

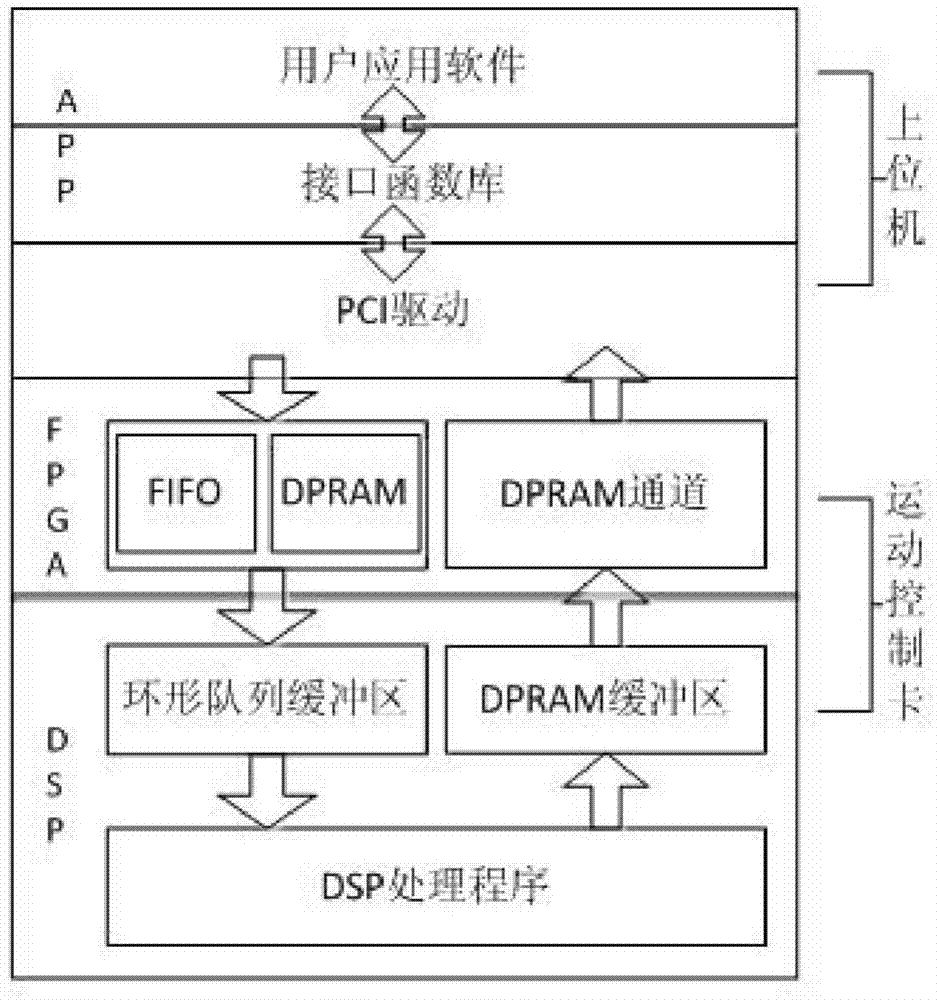

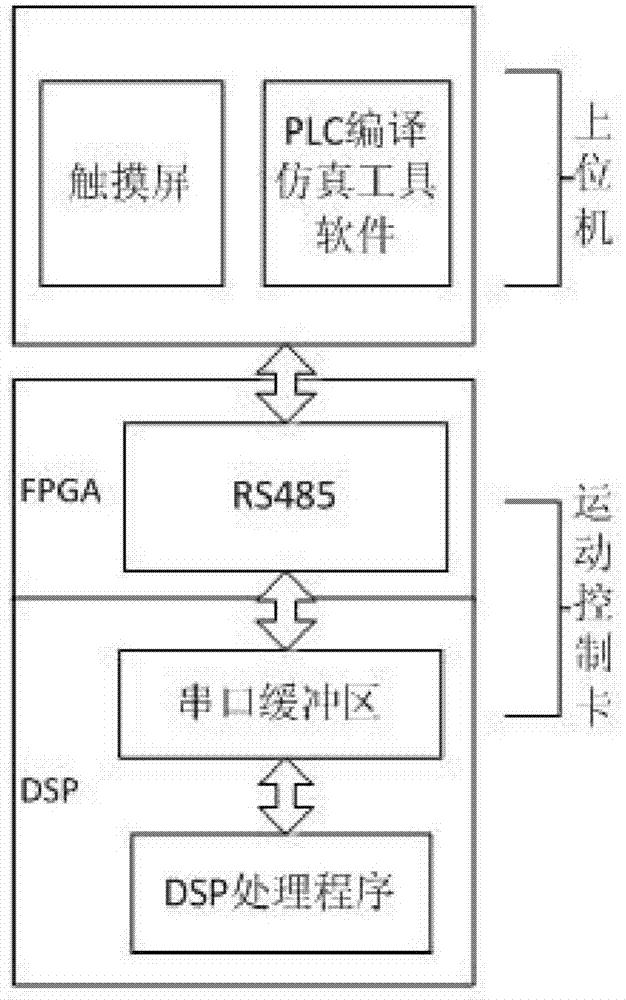

[0030] Such as figure 1 As shown, a multi-axis motion control system includes a host computer, a multi-axis motion control card, and an actuator. The host computer is used to issue motion instructions and receive and display status information of the motion control card; The multi-axis motion control card is used to receive the motion instructions issued by the upper computer, and according to the instructions to realize the communication interface, pulse output, I / O state management, axis trajectory planning, and execute PLC operations; the actuator is used to receive multi-axis The pulse signal output by the motion control card drives multi-axis motion according to the pulse signal.

[0031] In the motion control card, FPGA is responsible for implementing functions such as communication interface, pulse output and I / O status management, while DSP is responsible for trajectory planning and execution of complex operations such as PLC. FPGA adopts EP4CE40F23C8N of ALTERA Company,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com