Cable vulcanization production line

A production line and cable technology, applied in the manufacture of cables/conductors, insulation of conductors/cables, electrical components, etc., can solve the problems of scratching the rubber surface, easy adhesion of dust impurities, large cable cross-section, etc., to improve product quality , Improve the effect of wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

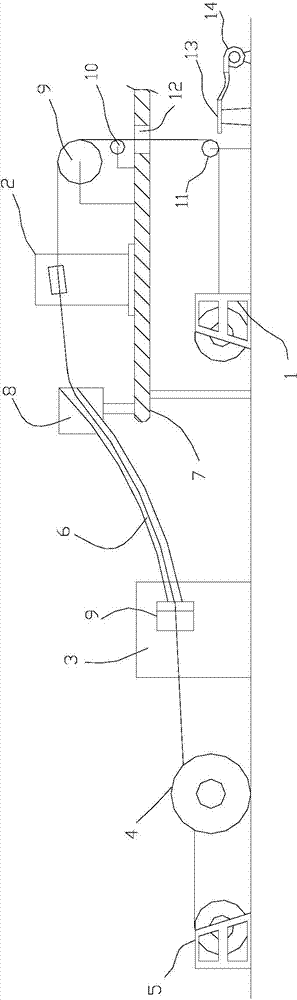

[0019] Such as figure 1 As shown, a cable vulcanization production line described in this embodiment includes a pay-off device 1, an extruder 2, a sealed water tank 3, a traction device 4, a take-up device 5, a catenary vulcanization pipe 6 and a bracket 8, One end of the catenary vulcanization tube 6 is fixed on the bracket 8, and the other end is connected with the outlet seal 9 on the sealed water tank 3; the take-up device 5 and the traction device 4 are sequentially located on the left side of the sealed water tank 3; it is characterized in that Including a platform 7, the pay-off device 1 is located below the platform 7, the support 8 and the extruder 2 are located above the platform 7, the support 8 is located on the upper right side of the sealed water tank 3, and the extruder 2 is located on the right side of the support 8. The right side of the machine 2 is provided with a first guide wheel 9, and a tensioning wheel 10 is provided below the first guide wheel 9; the r...

Embodiment 2

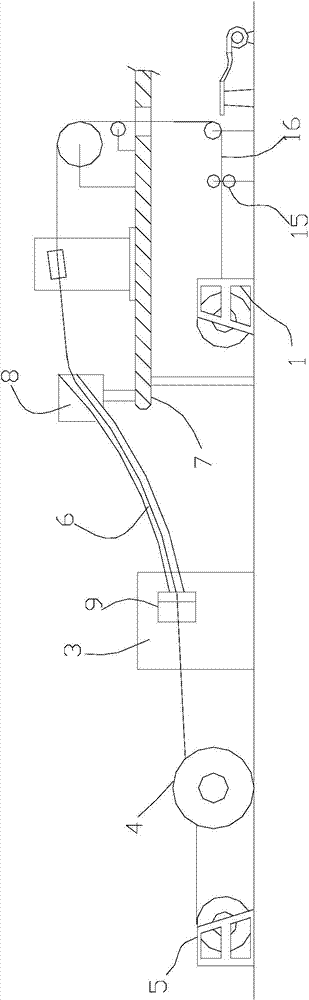

[0024] Such as figure 2 As shown, the cable vulcanization production line described in this embodiment is different from that of Embodiment 1 in that two upper and lower cleaning rollers 15 are arranged between the pay-off device 1 and the second guide wheel 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com