Harmonic suppression band-pass filter and manufacturing method thereof

A band-pass filter and harmonic suppression technology, applied in waveguide devices, impedance networks, electrical components, etc., can solve the problems of complex design process, low accuracy, inconvenient production, etc., and achieve simple structure and high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

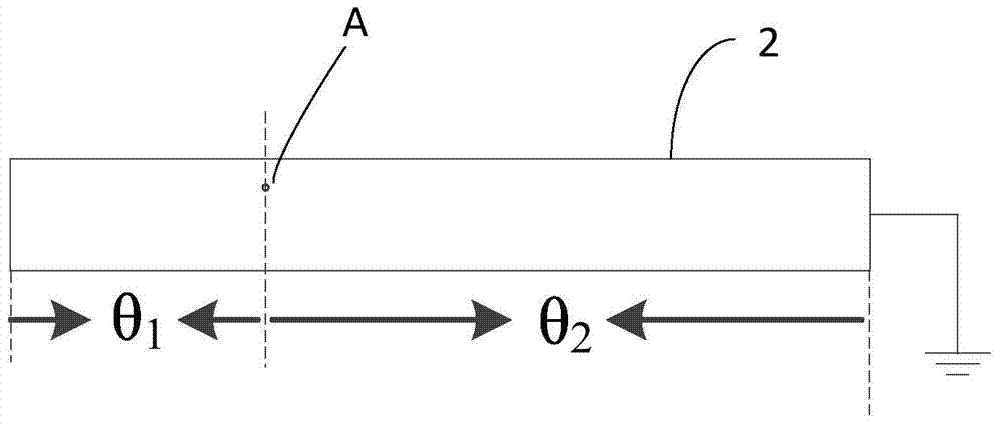

[0031] Harmonic suppression band-pass filter provided by the present invention and manufacturing method adopt the predetermined point A on two single-impedance resonators 2 (as image 3 shown) as the input feed point and output feed point. The predetermined point A is the zero point of the third harmonic voltage of the single impedance resonator 2, and the input microstrip line 3 and the output microstrip line 4 are orthogonally coupled with the corresponding single impedance resonator 2 at the predetermined point A, so that the single impedance resonates The third harmonic of the filter 2 cannot respond, so that the harmonic suppression bandpass filter 2 has the effect of filtering out the third harmonic, and because the predetermined point is obtained by precise calculation, it has high accuracy and simple production process Beneficial effect. The present invention will be described in further detail below in conjunction with the accompanying drawings.

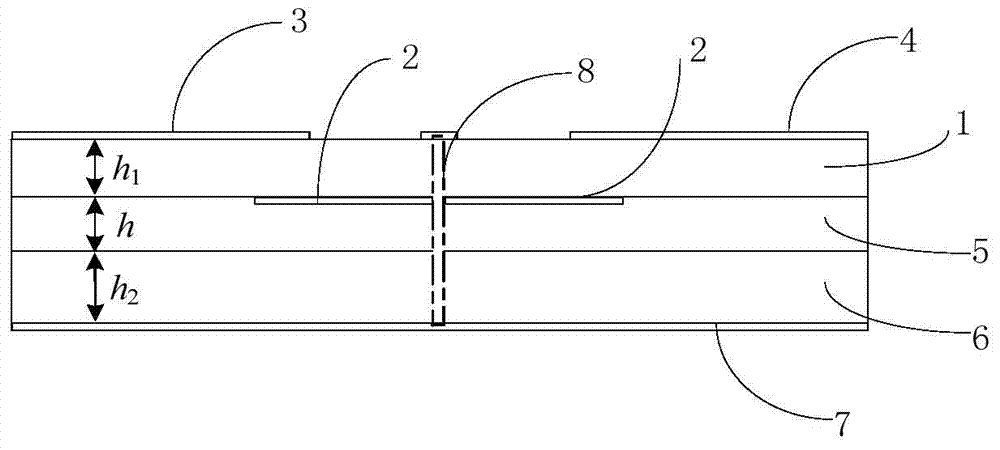

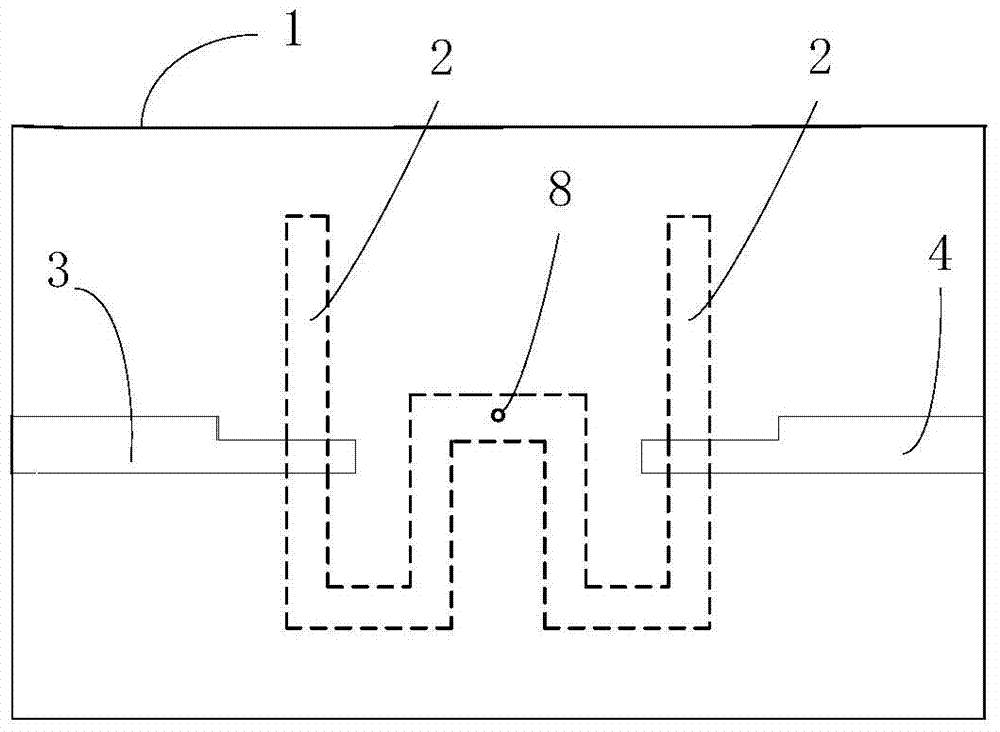

[0032] figure 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com