Reciprocating Engines and Engine Blocks

An engine, reciprocating technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve problems that hinder turbocharger operation, engine operation, cylinder filling effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

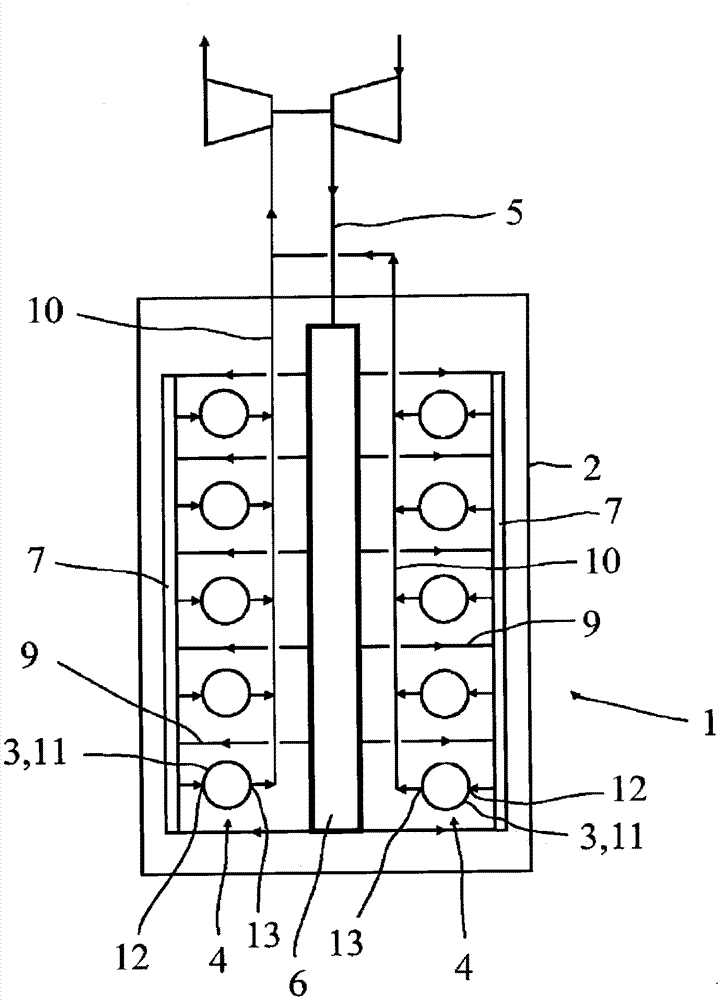

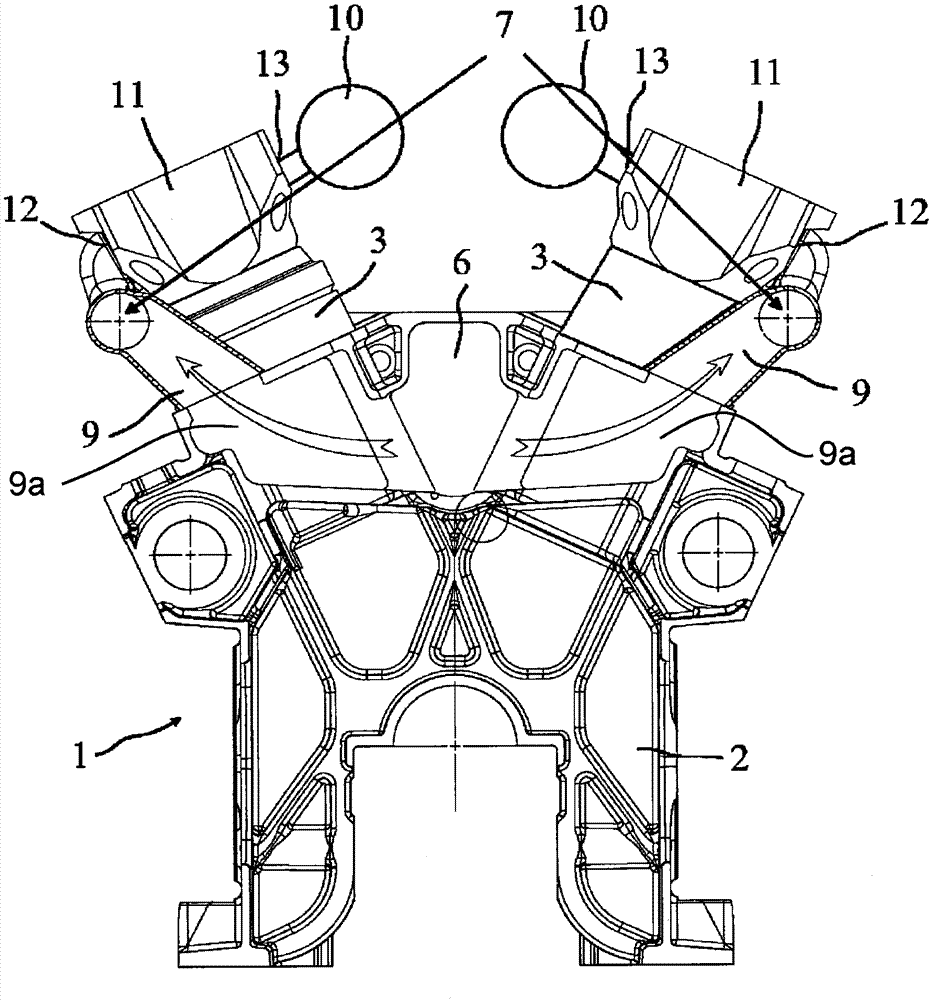

[0012] figure 1 A multi-cylinder reciprocating engine 1 is disclosed. The engine 1 can be a large reciprocating engine, a two-stroke or four-stroke engine. Here, a large reciprocating engine is referred to as an engine that can be used, for example, as a main engine and a secondary engine in a ship or in a power plant for generating heat and / or electricity. The engine 1 comprises an engine block 2 with cylinders 3 arranged in two banks 4 in a V-shaped configuration. Typically, engine 1 includes 6 to 24 cylinders 3 .

[0013] The reciprocating engine 1 comprises inlet channels 5 for guiding intake air into the cylinders 3 . The engine 1 can adopt one-stage or multi-stage turbocharging 8 . exist figure 1 In the embodiment described above, the engine is one-stage turbocharged and provided with one turbocharger 8, however, each cylinder bank 4 may be provided with a separate turbocharger 8 if desired. The inlet channel 5 is provided with a main air intake receiver 6 and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com