Production line processing equipment of dried turnip

A processing equipment and radish technology, applied in the field of dried radish assembly line processing equipment, can solve the problems of difficult to guarantee product quality, low efficiency of manual cleaning and slicing, occupying a large space, etc., achieving fast processing speed, uniform and tidy slicing, and good safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

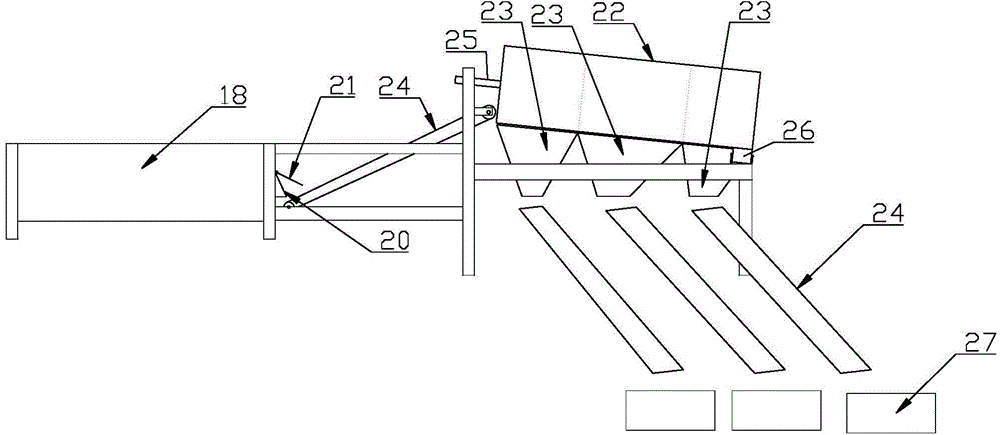

[0023] Such as figure 1 , 2 , 3, 4, 5, 6 and 7, a dry radish assembly line processing equipment includes a cleaning device, a sorting device, and an automatic radish slicer 27.

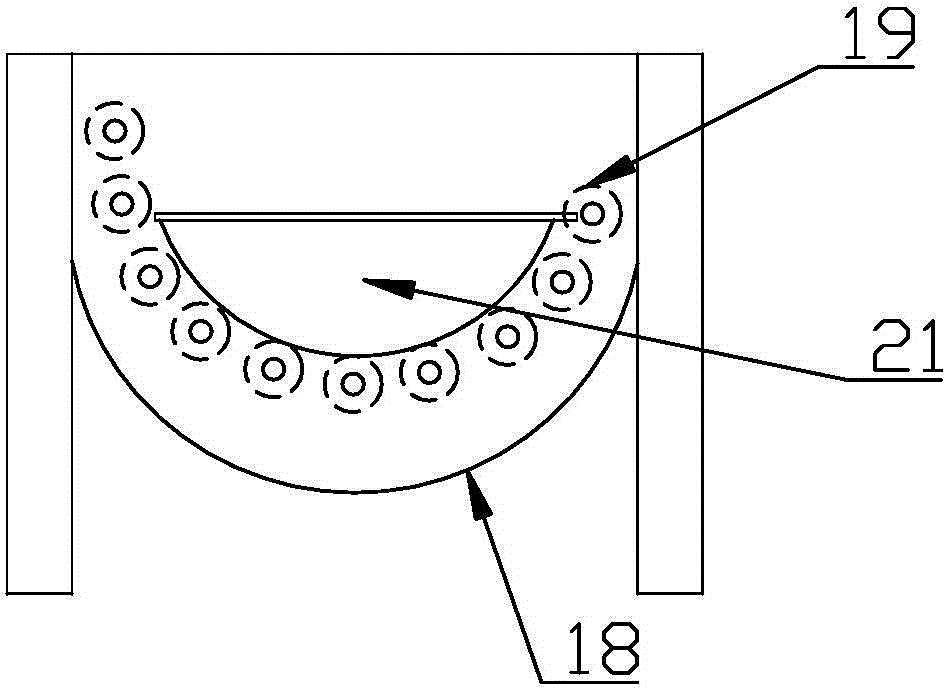

[0024] Cleaning device comprises cleaning tank 18 and cleaning brush roll 19, and cleaning tank 18 is installed on the frame, and one side of cleaning tank 18 has discharge port 20, and a plurality of cleaning brush rolls 19 is arranged along cleaning tank 18 lengthwise, and multiple The cleaning brush rollers 19 are arranged in an arc on the cross-sectional direction, and the gap between the cleaning brush rollers 19 is less than the diameter of the radish. 18 has a door 21 that closes the discharge port 20, and the cleaning brush roller 19 is driven to rotate by a motor;

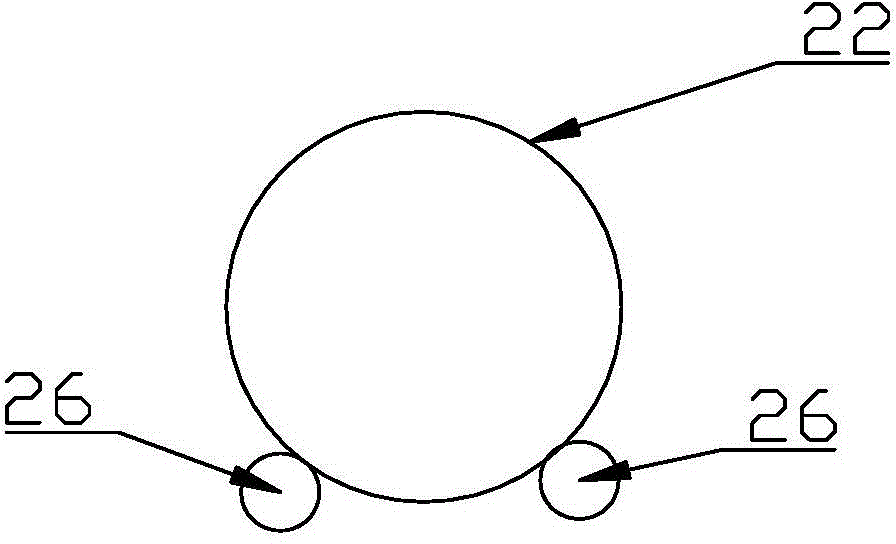

[0025] The sorting device comprises a sorting net tube 22 and a sorting collection bucket 23, the sorting net tube 22 and the sorting collection bucket 23 are installed on the frame, the two ends of the sorting net tube 22 are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com