A low resilience high support coronary artery degradable stent

A coronary, low-rebound technology, applied in the field of low-rebound high-support coronary degradable stents, can solve the problems of inability to overcome large radial rebound, easy-rebound support force of stents, poor mechanical strength, etc., to prevent The effect of rebound, long-term support, and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

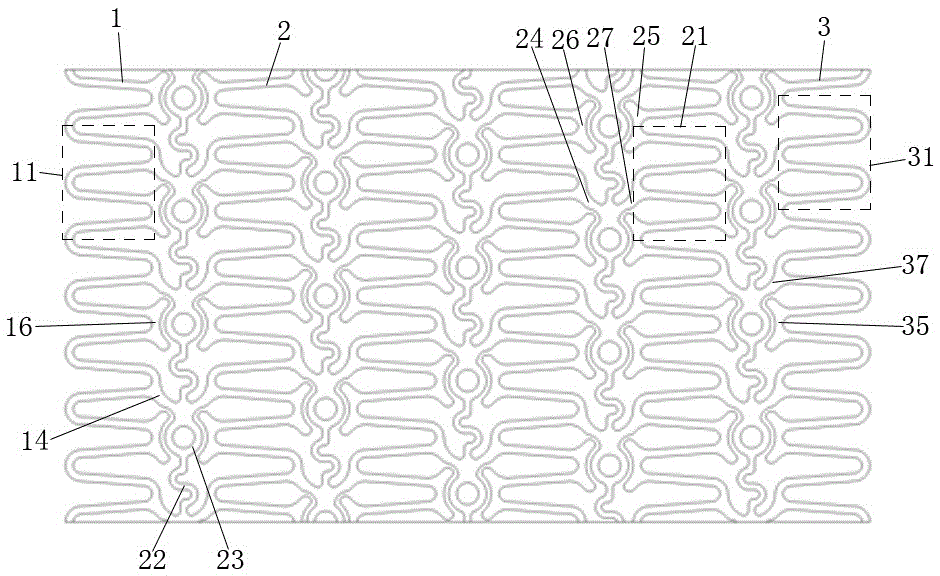

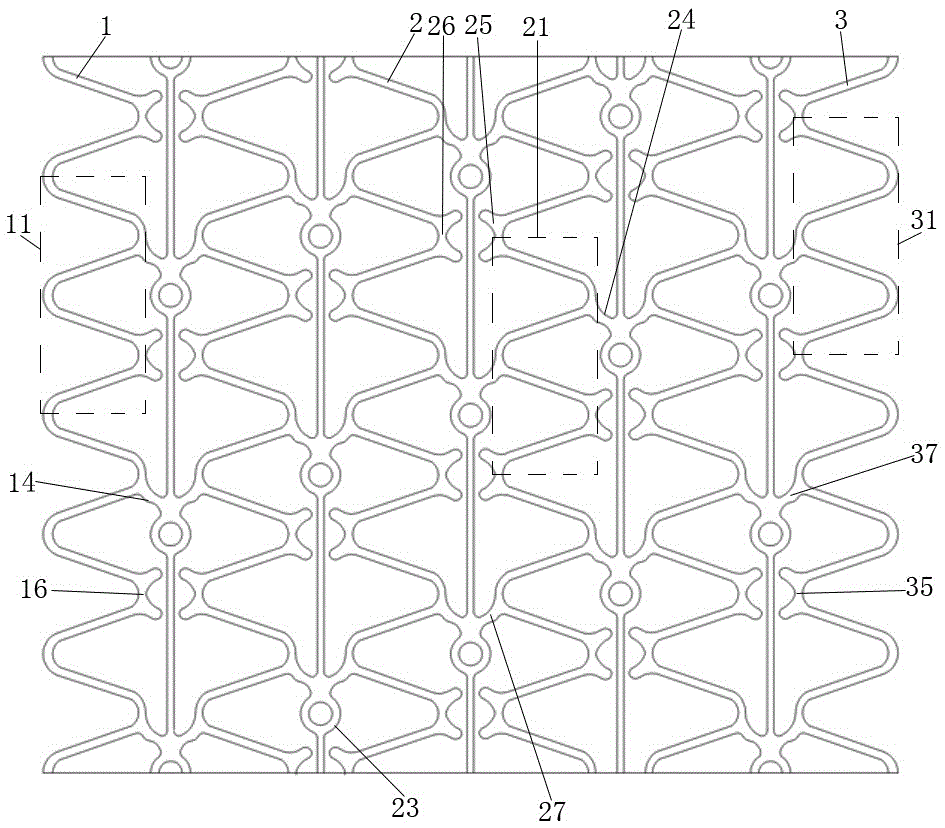

[0013] Such as figure 1 As shown, a low-resilience high-support coronary degradable stent of the present invention is an integral tubular network structure formed by connecting beam-column units 1 at the head end, beam-column units 3 at the tail end and several columns of beam-column units 2 in the middle section. . The beam-column unit in the middle section includes several W-shaped structures 21, and the W-shaped structures 21 are placed sideways. The W-shaped structures in adjacent columns are arranged in a staggered manner, and the connection of two adjacent W-shaped structures in the beam-column unit in the middle section of each column extends to both sides to form a half bracket-like structure 25, and a bottom end of the W-shaped structure extends to both sides Form a half bracket-like structure 26, the other bottom end of the W-shaped structure extends to one side to form a bottom extension end 24, the top end of the W-shaped structure extends to one side to form a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com