Water mist fire extinguishing system

A fire extinguishing system and fine water mist technology, which is applied in fire rescue and other fields, can solve the problems of short range, limited use, and high cost of water mist, and achieve the effects of increasing the initial velocity of water mist, reducing working pressure, and stabilizing the particle size of water mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

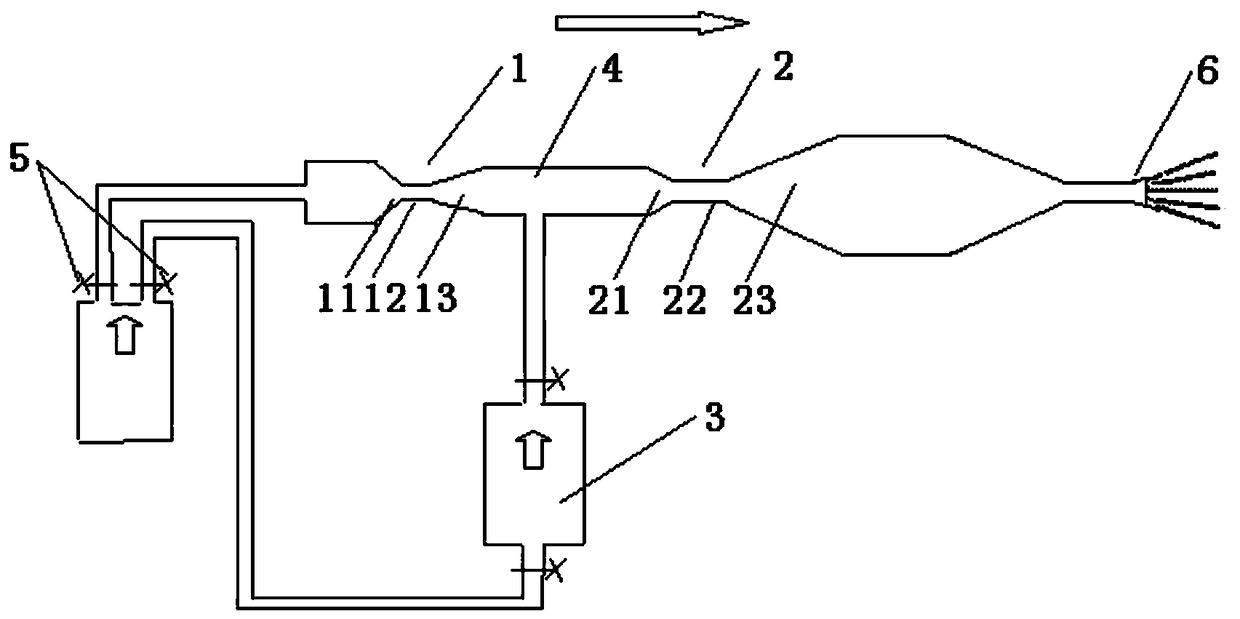

[0023] A specific embodiment of a fine water mist fire extinguishing system, its composition is as follows figure 1 As shown, it includes the intake system, the first Laval nozzle 1, the water tank 3, the ejector 4, the second Laval nozzle 2 and the nozzle 6, wherein the compressed air output of the intake system is two ways, and one way passes through the pipe One way is connected with the first Laval nozzle 1, the other way is connected with the water tank 3 through the pipeline, and each way is controlled by the valve 5 respectively; the first Laval nozzle 1 and the water tank 3 are connected with the ejector 4 through the pipeline , and the air inlet and water outlet of the water tank are controlled by valves; the ejector 4 is connected with the second Laval nozzle 2 and the nozzle 6 in turn.

[0024] The inlet diameter of the first Laval nozzle 1 is 8.0 mm, the diameter of the throat pipe 12 is 1.3 mm, the outlet diameter is 5.0 mm, and the length of the expansion section...

Embodiment 2

[0028] The structure and operation process of this embodiment are the same as in Embodiment 1. The inlet diameter of the first Laval nozzle is 8.2mm, the throat diameter is 1.5mm, the outlet diameter is 5.2mm, and the length of the expansion section is 22mm; The inlet diameter of the Laval nozzle is 5.2mm, the diameter of the throat is 2.7mm, the diameter of the outlet is 10.2mm, and the length of the expansion section is 44mm. Two Laval nozzles are connected end to end with a high-pressure water pipe with a diameter of 5.4mm.

[0029] In this embodiment, the flame in the oil tank with a diameter of 5.8 m after burning a mixture of 3 / 4 gasoline and 1 / 4 water is extinguished in the oil tank, and the total water consumption is less than 8.5 L, and it takes about 20 seconds.

Embodiment 3

[0031] The structure and operation process of this embodiment are the same as in Embodiment 1. The inlet diameter of the first Laval nozzle is 7.8mm, the throat diameter is 1.1mm, the outlet diameter is 4.8mm, and the length of the expansion section is 21mm; The inlet diameter of the Val nozzle is 4.8mm, the throat diameter is 2.3mm, the outlet diameter is 9.8mm, and the length of the expansion section is 41mm; the outlet diameter of the first Laval nozzle and the inlet diameter of the second Laval nozzle are both The diameter is 5.0mm, and two Laval nozzles are connected end-to-end with a diameter of 5.2mm high-pressure water pipe.

[0032] In this embodiment, the flame in the oil tank with a diameter of 5.8 m after burning a mixture of 2 / 3 diesel oil and 1 / 3 water is extinguished in the oil tank, and the total water consumption is less than 9 L, and the time is about 28 s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com