Automatic skillet grinding machine

A technology of grinding machine and grinding mechanism, applied in grinding machine, grinding/polishing equipment, grinding/polishing safety device, etc., can solve the problems of inconvenient operation, inconvenience, large smoke and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments.

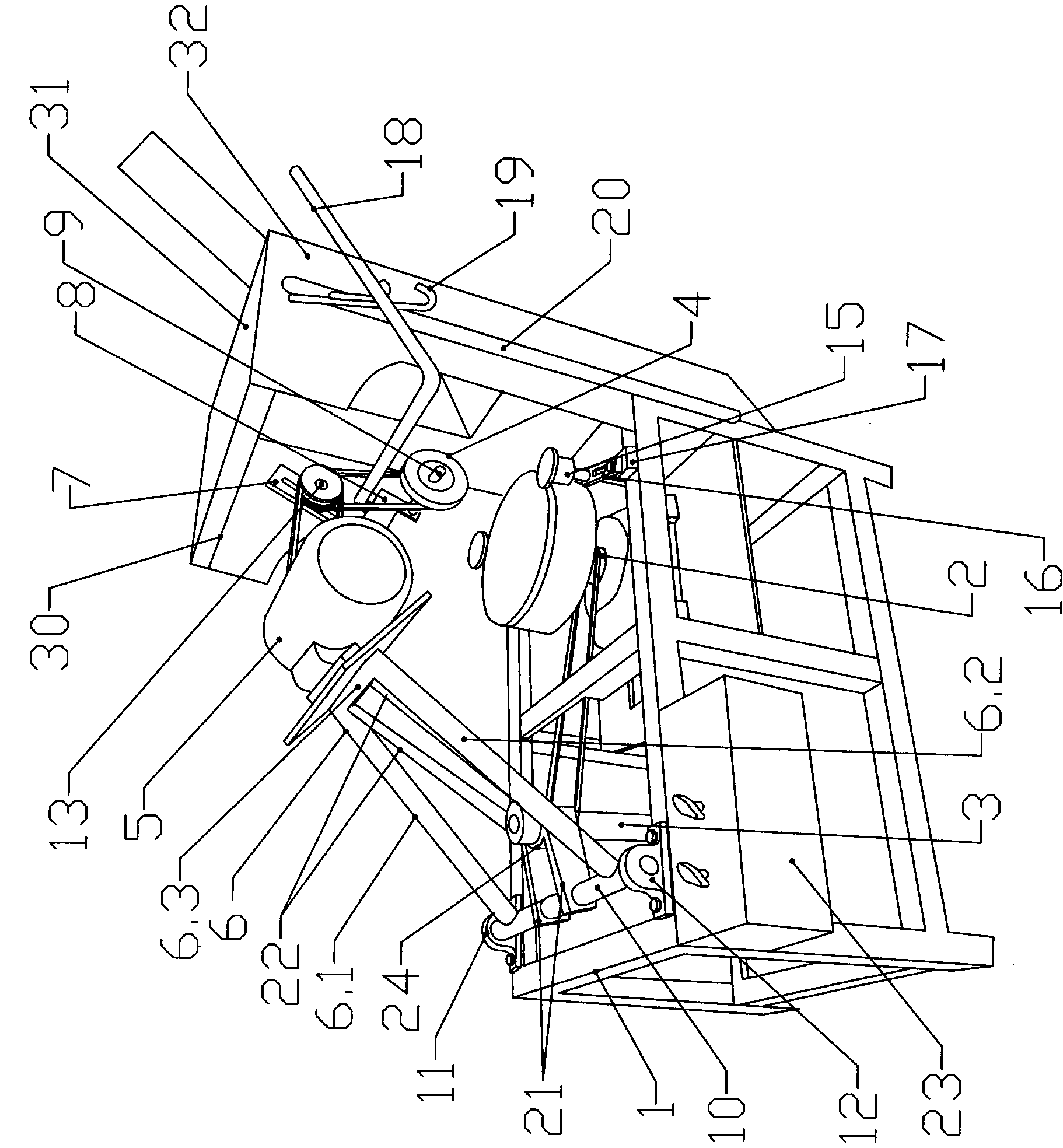

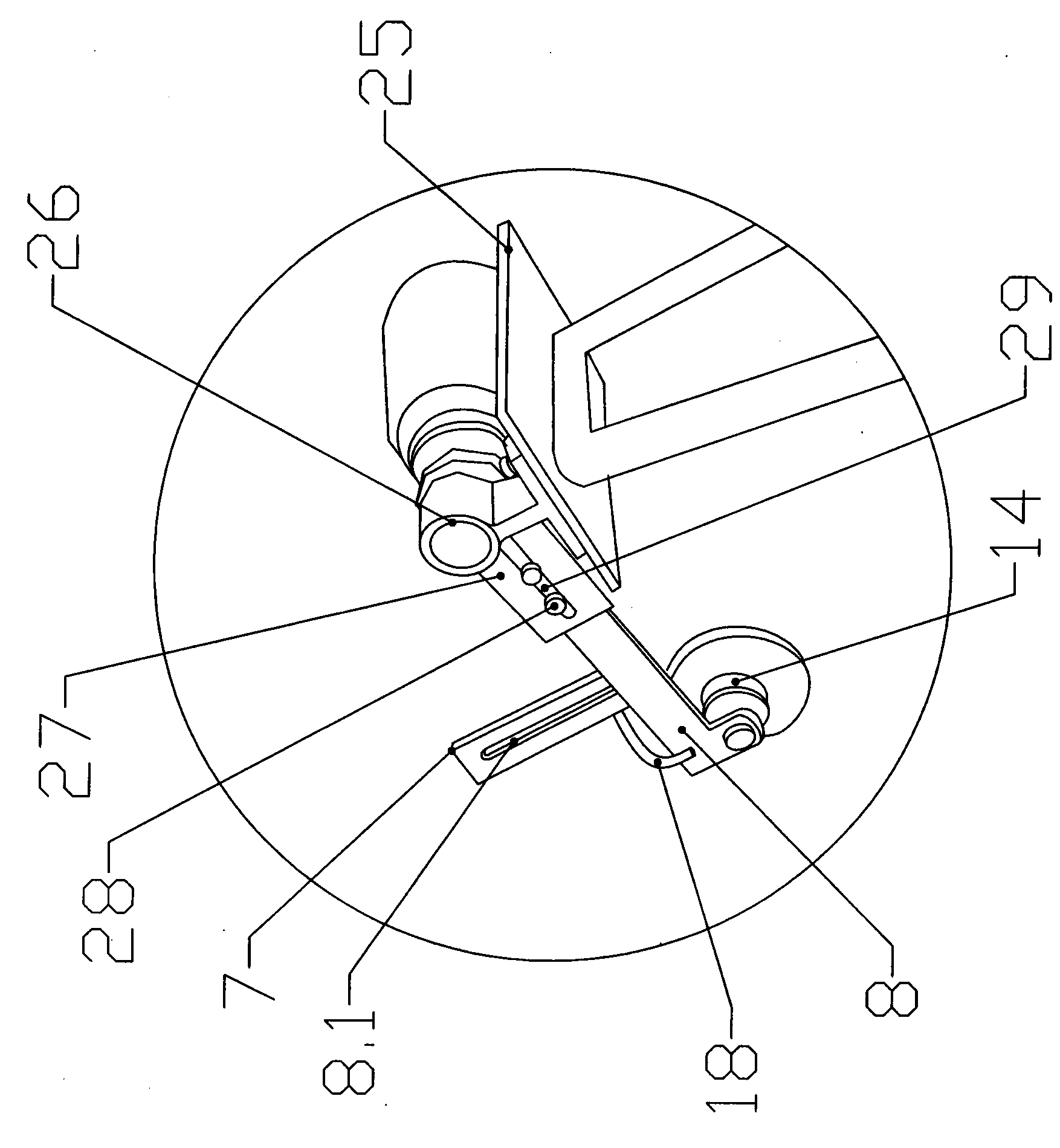

[0021] Such as figure 1 , 2 As shown, a cast pot automatic grinder, the grinder includes a frame 1, a cast pot rotating device, a grinding mechanism, the frame 1 is also provided with a dust collection cover 30, the dust collection cover 30 is located The front end of the casting pot rotation device, the dust collection cover 30 is in a square half-open state, the upper part is a square cover 31 structure, and the two sides are two baffles 32, forming a semi-closed structure. The semi-closed structure is arranged in the casting Right above the pot rotating device, the dust can be fully discharged outside through its inlet, and a vacuum cleaner can also be installed at the inlet of the semi-closed dust collection cover 30, which can be installed according to the size of the dust. All are equipped with a semi-enclosed dust collection cover 30, which can fully carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com