High-temperature superconducting magnetic suspension vehicle system

A high-temperature superconducting and magnetic levitation technology, which is applied in high-temperature superconducting applications and the field of high-temperature superconducting magnetic levitation, can solve the problems of not considering the placement direction of blocks, the performance of magnetic levitation needs to be improved, and the ability to capture the magnetic field of permanent magnet tracks is not high. Convenient, easy-to-promote effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

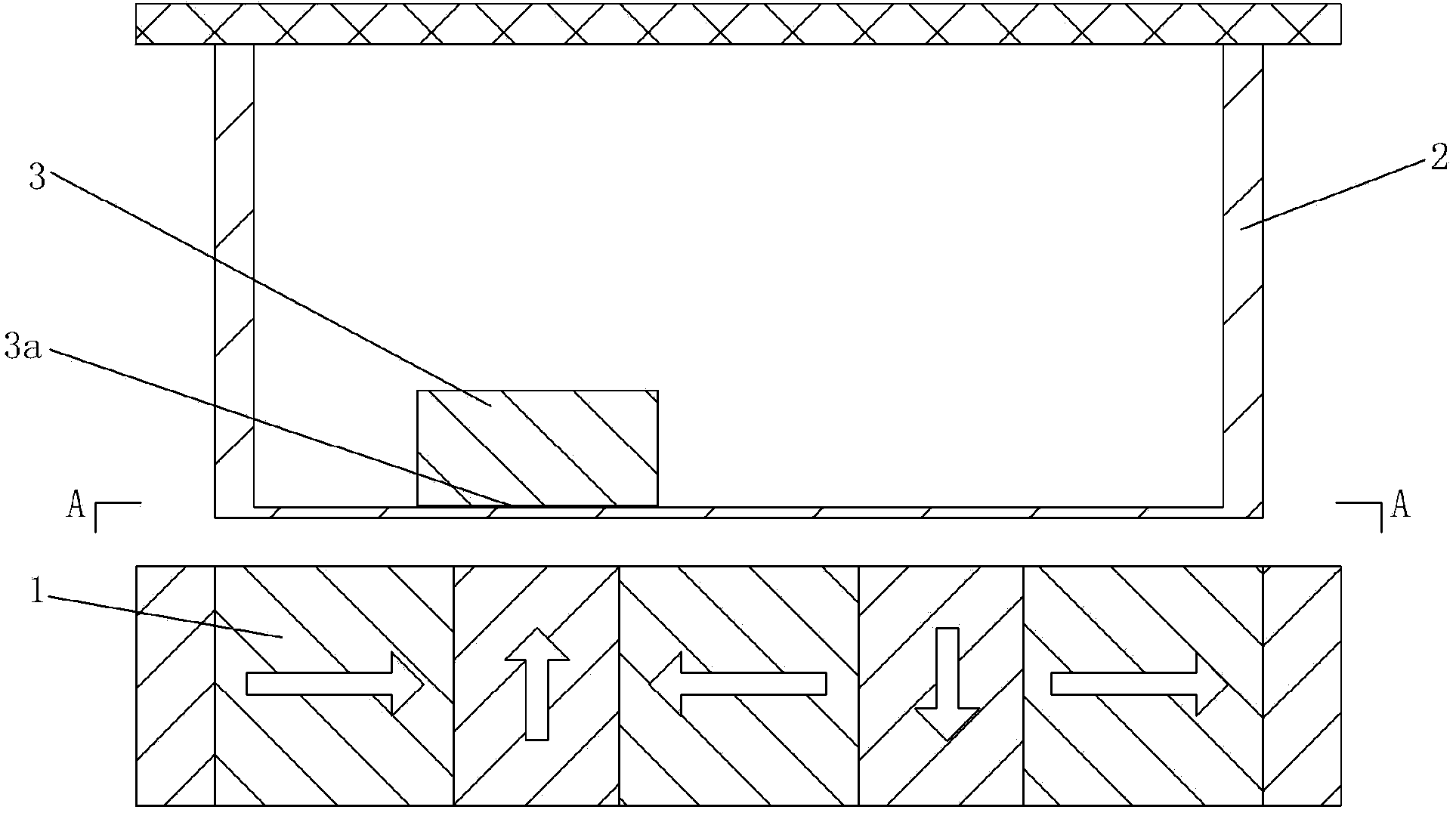

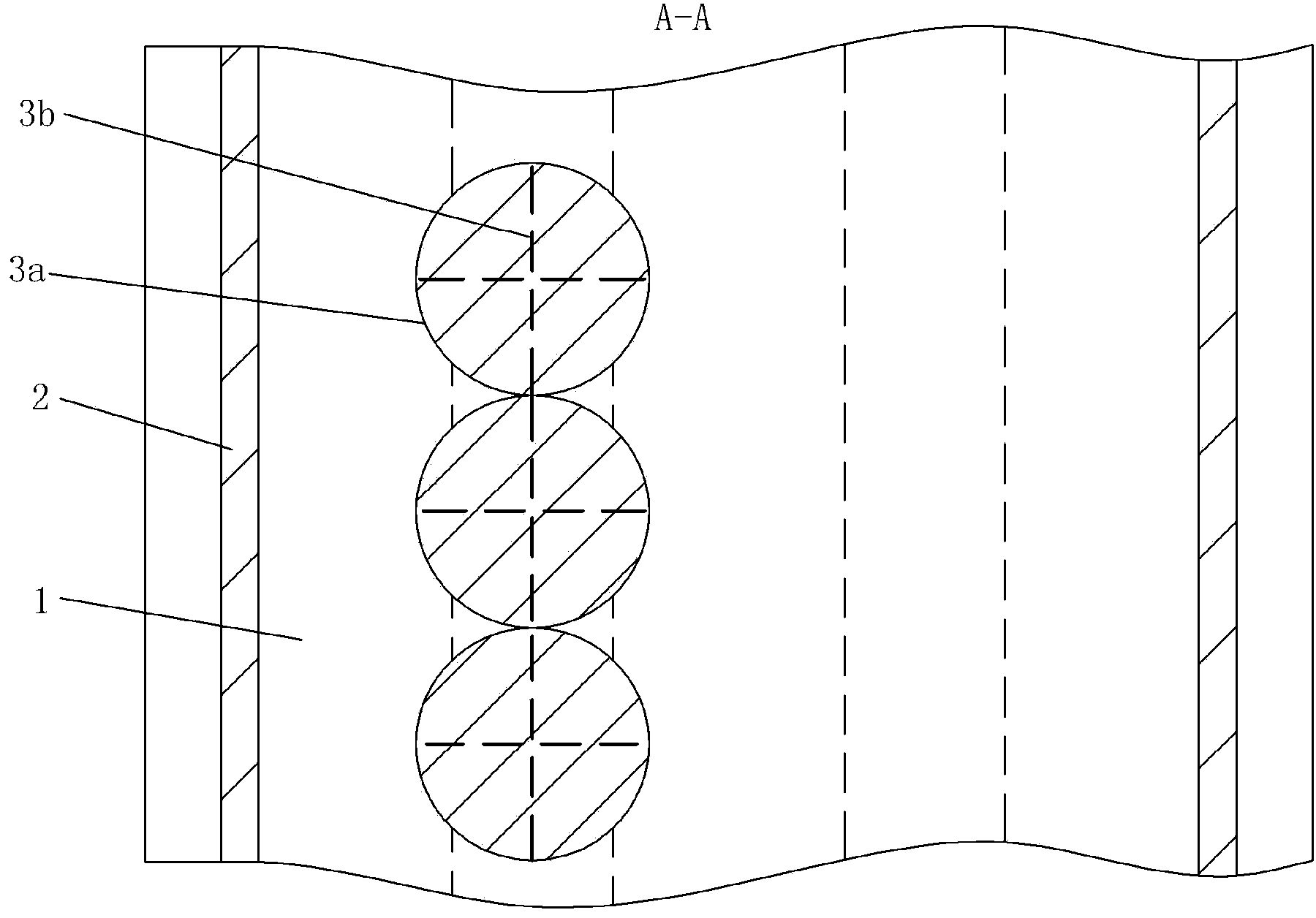

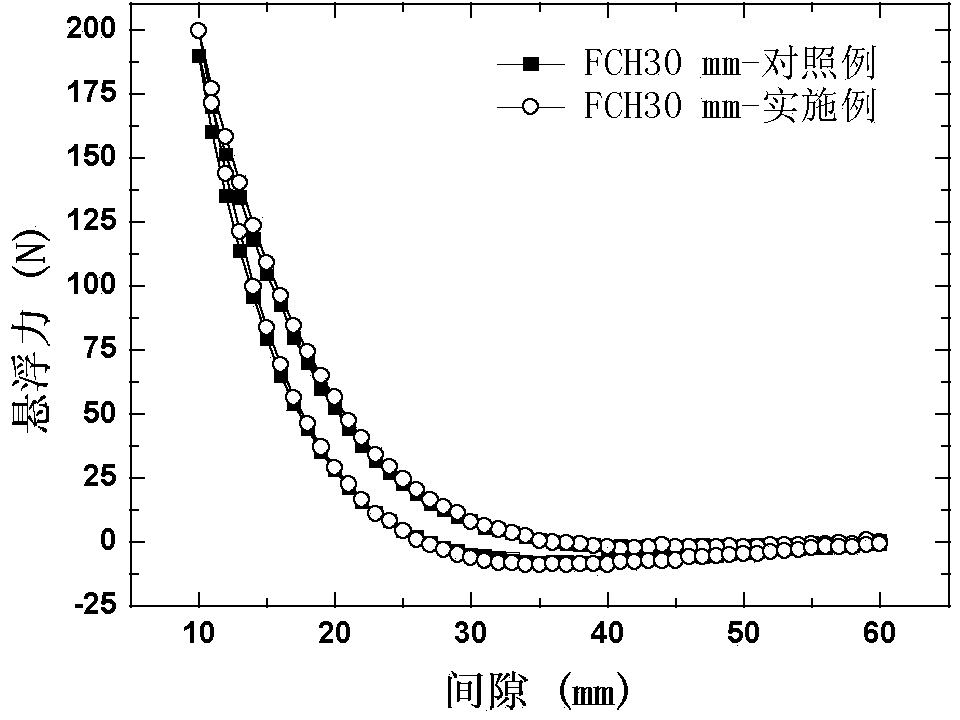

[0017] Such as figure 1 and figure 2 As shown, a specific embodiment of the present invention is a high-temperature superconducting maglev vehicle system, including a permanent magnet track made of permanent magnets and magnetic gathering materials, a suspension vehicle body above the permanent magnet track 1, and a vehicle body fixed on the suspension The low-temperature container 2 at the bottom of the car body, in which a single or multiple high-temperature superconducting blocks 3 are fixed; it is characterized in that: the seed surface 3a of the superconducting block 3 faces the permanent magnet track 1, and the seed A seed crystal growth boundary line 3b of the crystal plane 3a is consistent with the extending direction of the permanent magnet track 1 .

[0018] figure 1 It is shown that the fixed superconducting bulk material 3 in the cryogenic container 2 of this example is one layer. In actual implementation, the superconducting bulk material 3 can also use two la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com