Gate type gangue turning device

A gangue-turning and door-type technology is used in transportation and packaging, lifting equipment in mines, etc. It can solve the problems of large floor space, low efficiency of lifting and gangue discharge, and poor safety performance, and achieves a small floor space, The effect of improving the utilization rate and waste removal efficiency, and improving the ability of turning waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

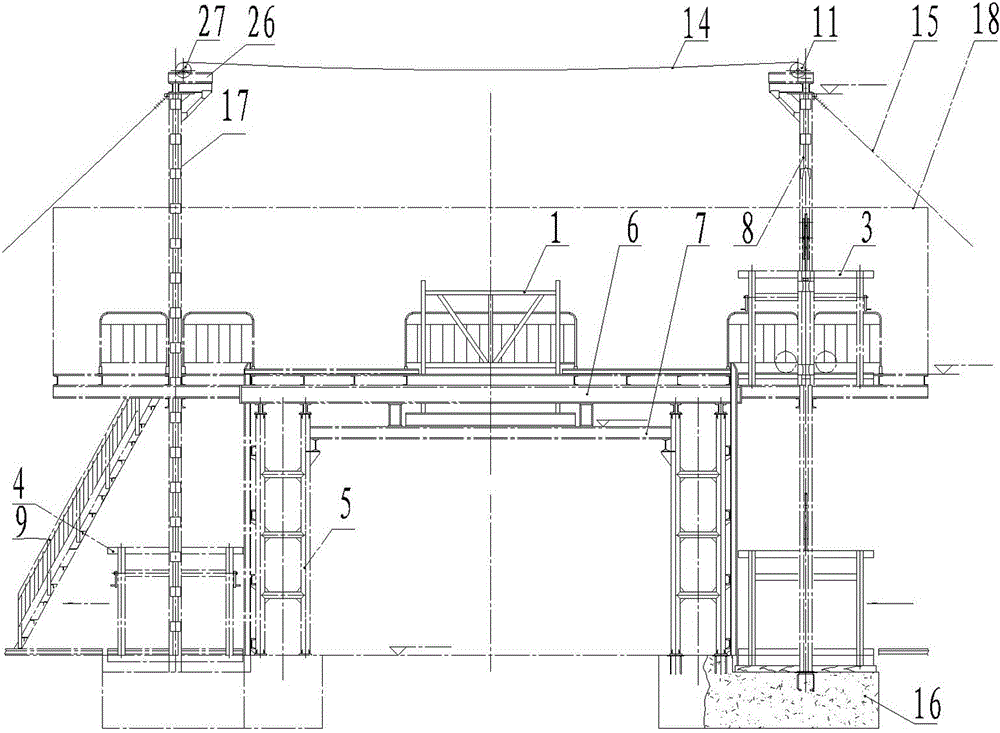

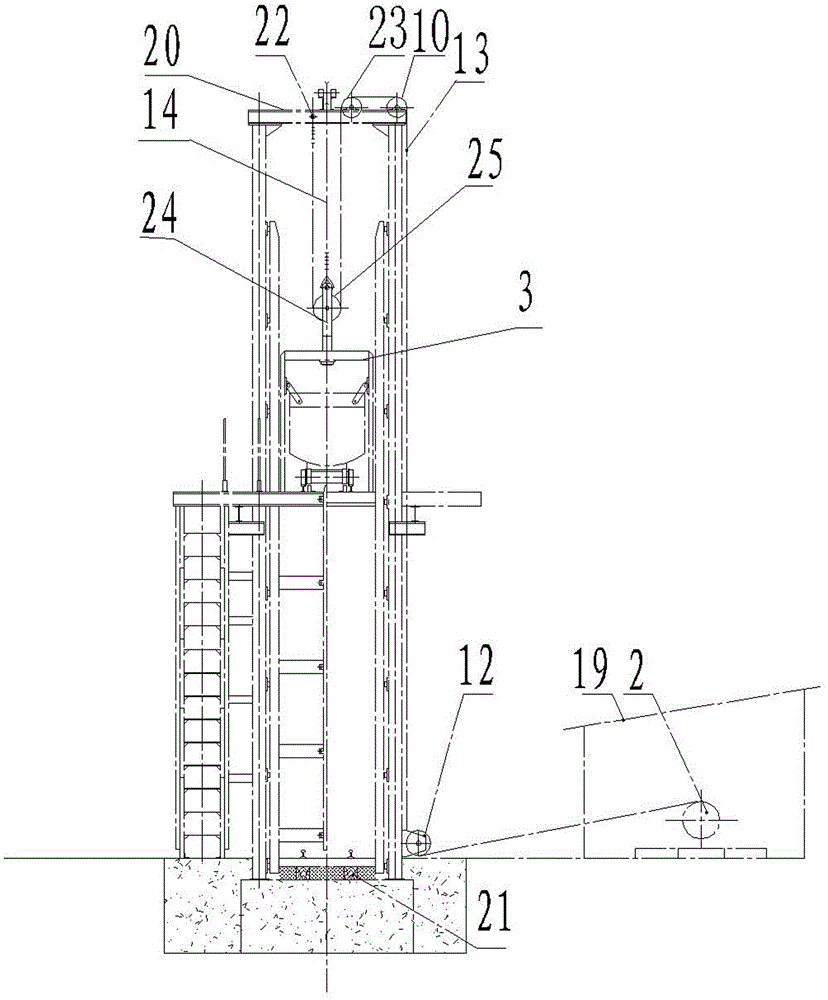

[0055] A gantry-type gangue turning device, comprising an electric dumper 1, a dumper platform 6, a dumper platform 7, a main cage lifting frame 8, an auxiliary pipe cage lifting frame 17, a main cage 3, an auxiliary cage 4 and a dispatching winch 2, Features:

[0056] The dumper platform 6 and the dumper platform 7 are arranged horizontally, and the dumper platform 7 is located below the dumper platform 6 .

[0057] The gangue turning platform 6 and the dumper platform 7 are supported by four support frames 5, each support frame 5 is fixed on the concrete foundation 16, and the electric dumper 1 is fixed on the gangue turning platform 6 and the dumper platform 7 to form a gangue turning frame body. Main cage hoisting frame 8 is vertically arranged on the right side of the gangue rack body, and is welded together with dumper platform 7, and the lower end of main cage hoisting frame 8 is fixed on the concrete foundation 16. The auxiliary cage lifting frame 17 is vertically ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com