Ship deck surface grinding equipment

A ship deck and equipment technology, which is applied in the field of ship deck surface grinding equipment, can solve the problems affecting the structural strength and reliability of ships, affecting the quality of coating coating, and reducing the safety of ships, so as to avoid human injury and prevent excessive damage. , The effect of small flatness error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

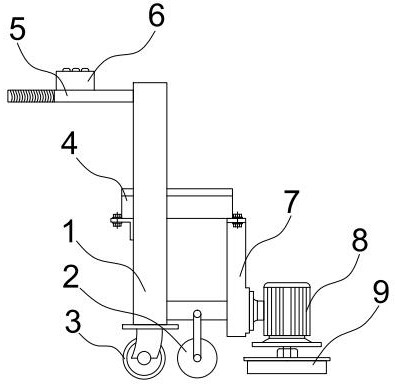

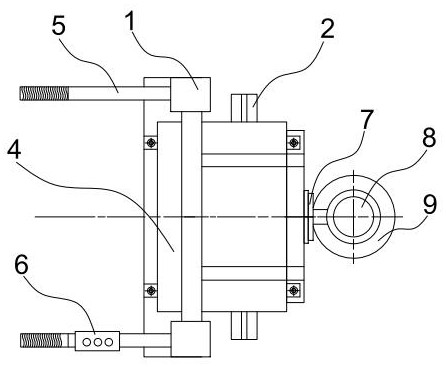

[0026] Such as figure 1 ,2 As shown, the ship deck surface grinding equipment includes a frame 1, a power distribution control box 4 is arranged in the middle of the frame 1, a fixed plate 7 is connected to the side of the power distribution control box 4, and a vertical motor is connected to the side of the bottom of the fixed plate 7. 8. A grinder 9 is connected below the motor 8, a handle 5 is provided on both sides of the top of the frame 1, a control switch 6 is provided on the handle 5, a roller 3 is provided on the bottom surface of the frame 1, and a fixed plate 7 is connected to the frame through a connecting rod. 1. The bottom side is connected, and the bottom of the connecting rod is connected with the rolling wheel 2. The bottom surface of the rolling wheel 3, the rolling wheel 2 and the grinder 9 are on the same level, and the hand-push grinding equipment is designed to replace manual or squatting / sitting on the deck. The deck surface rust removal method keeps wor...

Embodiment 2

[0030] The further optimization scheme of this embodiment on the basis of embodiment 1 is as follows: Figure 8 As shown, the rolling wheel 2 is a hollow structure, and a metal layer 201 is arranged around the outside. The surface of the metal layer 201 is evenly distributed with rectangular blocks, and a mandrel is arranged horizontally in the center, and the mandrel is surrounded by one end connected to the second bending bar 203. The other end of the bending bar 203 is connected to the first bending bar 202, the angle α between the second bending bar 203 and the first bending bar 202 is 120°-150°, the end of the first bending bar 202 and the metal layer 201 inner wall connection, the hollow rolling wheel 2 can reduce the manufacturing cost of the rolling wheel 2 and the weight of the device under the premise of ensuring the stability of the device. By setting the first and second bending bars, the rolling wheel 2 can be rolled When an obstacle is encountered, the impact str...

Embodiment 3

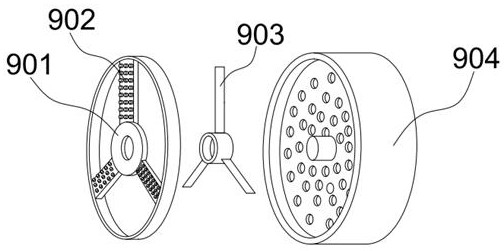

[0033] The further optimization scheme of this embodiment on the basis of embodiment 1 is as follows: Figure 3-7 As shown, the grinder 9 includes a cylindrical dust collection box 904, the center of the dust collection box 904 runs through the rotating shaft 801 of the motor 8, the surface of the dust collection box 904 is provided with a dust collection fan 903, and the upper part of the dust collection fan 903 is provided with a rotating disk 901, The dust collection fan 903 and the rotating disk 901 are connected to the rotating shaft 801, the top surface of the rotating shaft 801 is flush with the surface of the rotating disk 901, and the motor 8 is used to drive the rotating disk 901 to polish the surface of the deck and at the same time drive the dust collecting fan 903 to pass the polished rust debris through The wind force is collected into the dust collection box 904 so as to avoid the dust after grinding from harming the operator, and also prevent the rust debris fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com