Device for manufacturing polyimide coated optical fiber

A polyimide and coating technology, which is applied in the field of manufacturing equipment for coating optical fibers, can solve the problems of micro-crack expansion on the surface of optical fibers, failure of optical fibers, inability to precisely control the size of the coating and the concentricity of the coating, etc. The effect of sex and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

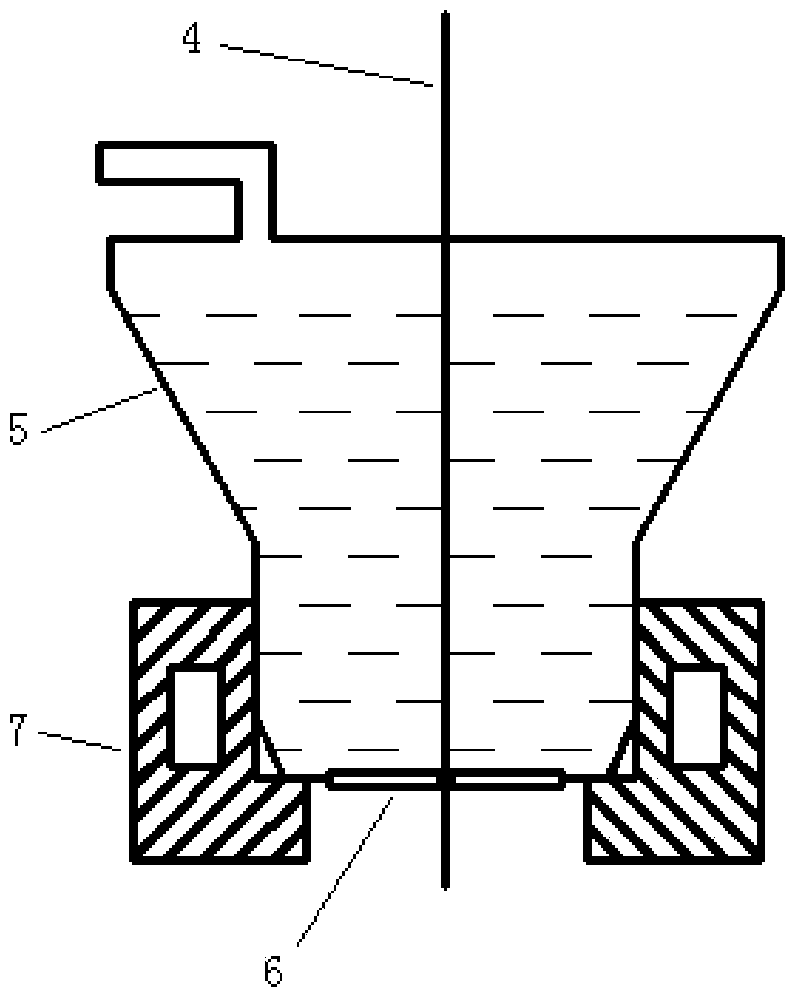

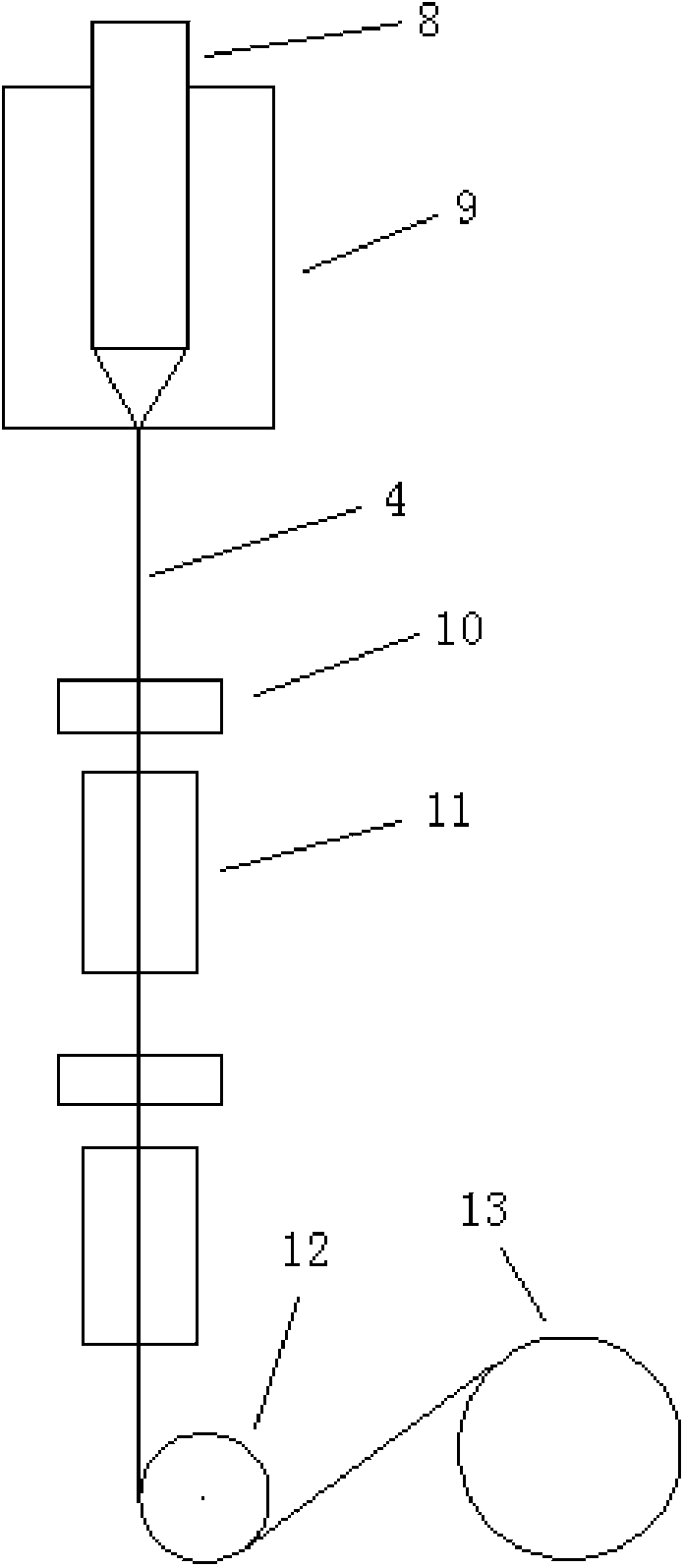

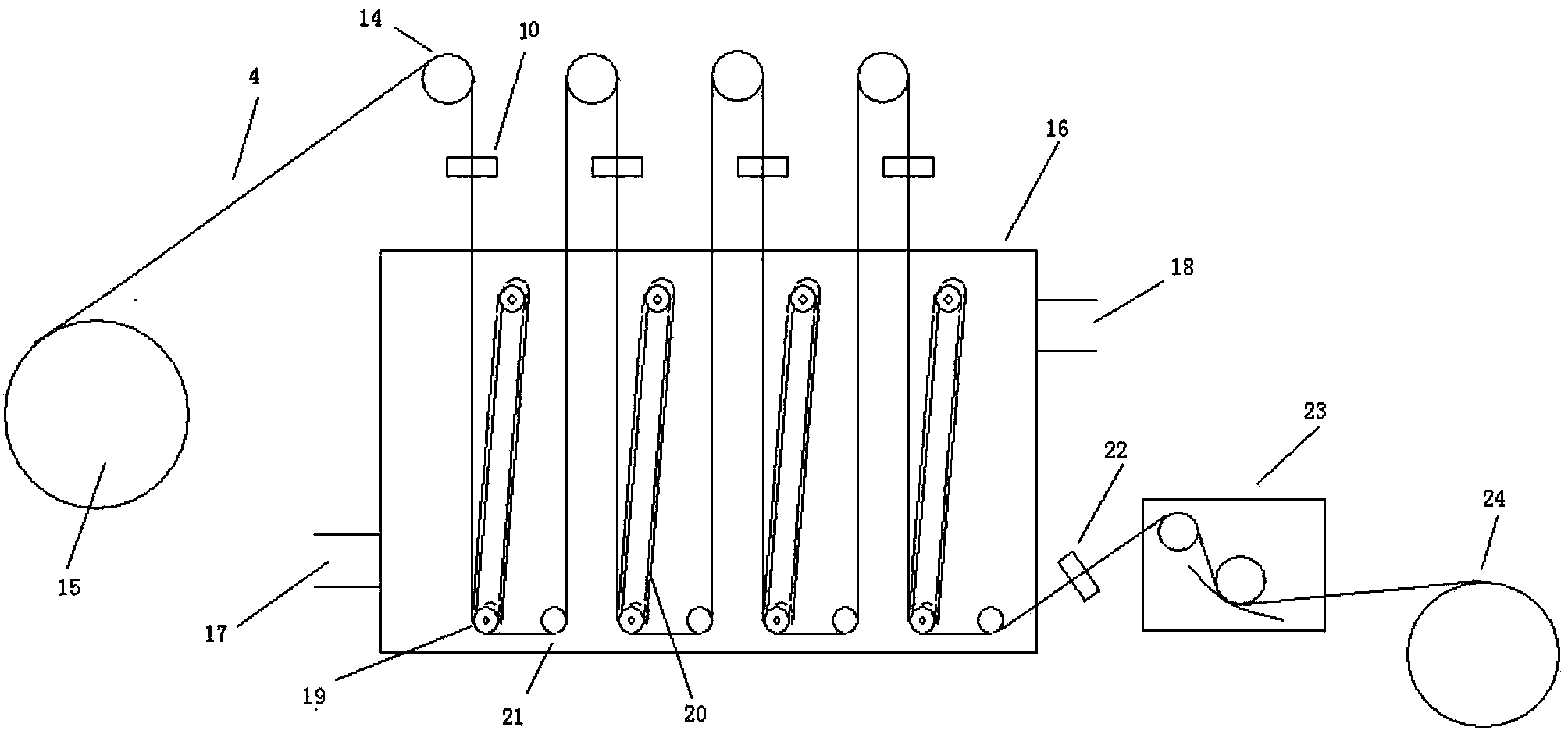

[0022] Reference figure 1 , figure 2 with image 3 , The present invention includes a high-temperature graphite induction furnace 9, an online coating and curing device, and an offline coating and curing device, and the online coating and curing device is arranged under the high-temperature graphite induction furnace 9. The online coating and curing device includes two alternately arranged coating units 10 and resistance heating furnaces 11. A resistance heating furnace 11 with a built-in quartz tube is arranged below the coating unit 10, and the quartz tube matches the inner wall of the resistance heating furnace 11. 11 is equipped with an air supply system and an air extraction system. The air supply system and the air extraction system can m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com