High-temperature resistant optical fiber production equipment and preparation method thereof

A production equipment, high temperature resistant technology, applied in the field of optical fiber, can solve the problems of complex polyimide-coated optical fiber equipment, single function, poor process control, etc., to avoid repeated purchase of equipment, save money, great flexibility and The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

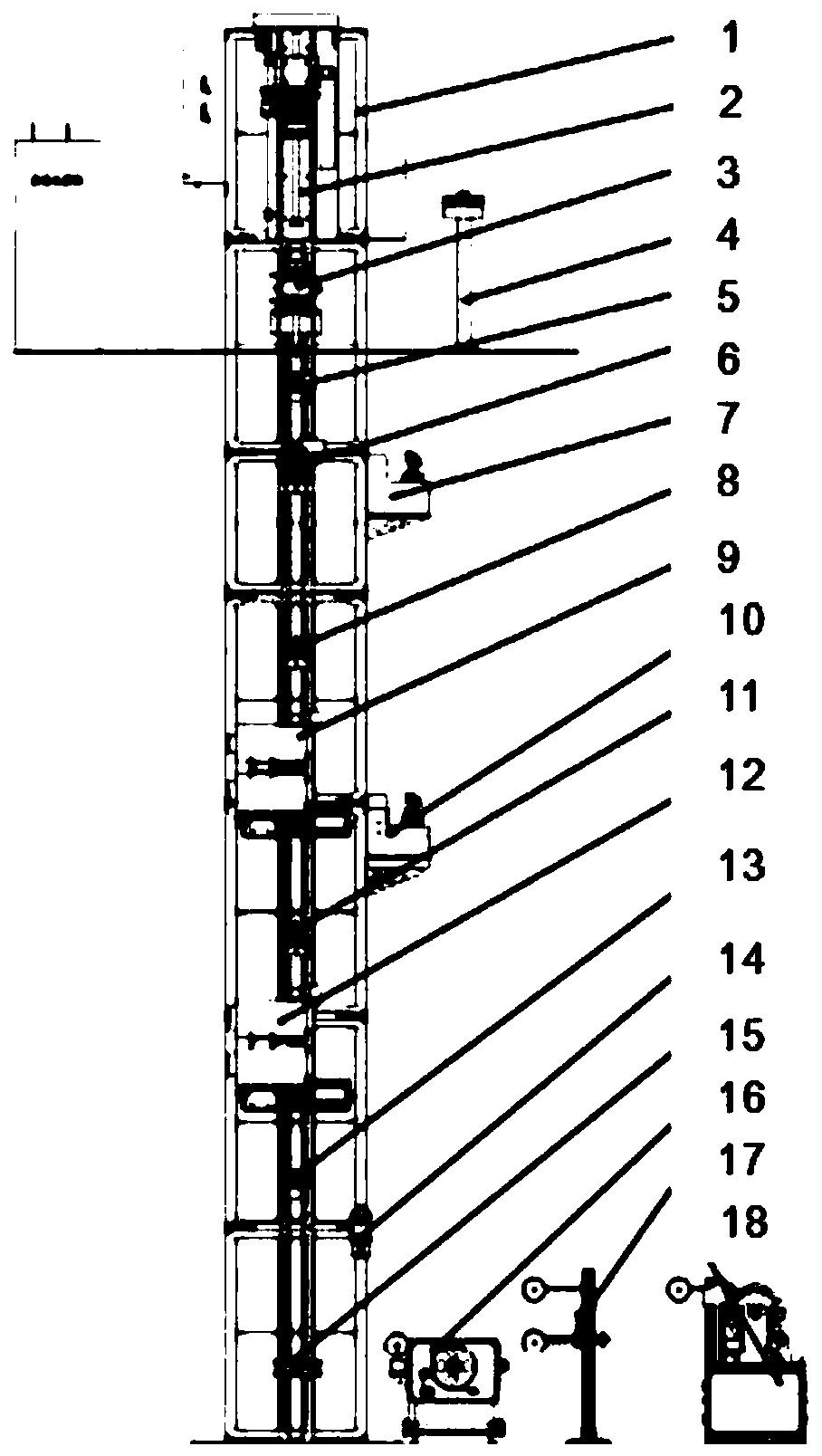

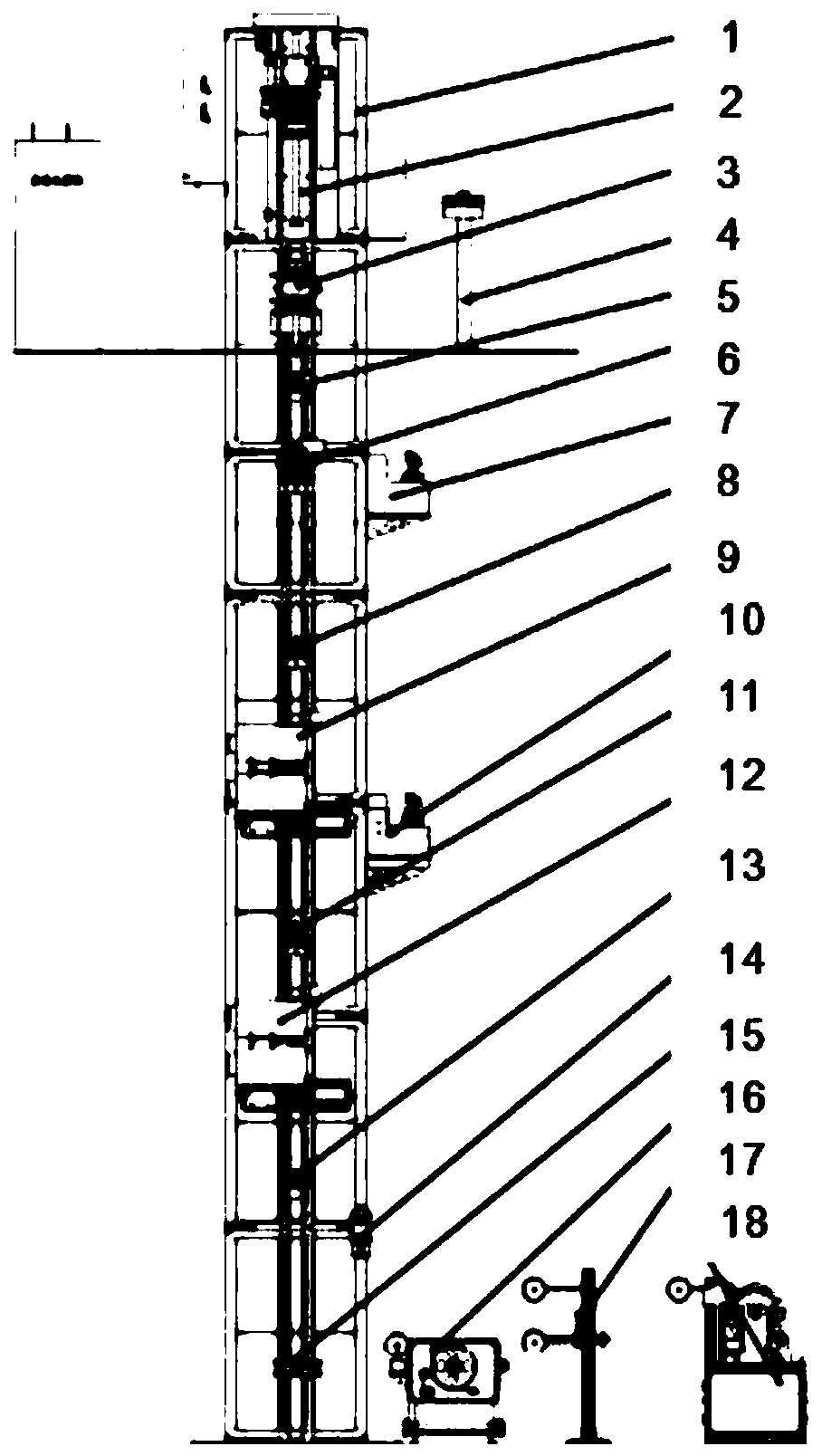

Image

Examples

preparation example Construction

[0040] The preparation process of high temperature resistant optical fiber comprises the following steps:

[0041] (1) Use a graphite furnace to melt and draw the optical fiber preform, wherein the heating temperature of the graphite furnace is 1700°C to 2200°C; among them, the optical fiber preform used for drawing can be different types of optical rods, and its outer diameter ranges It is φ20-30mm; the speed of wire drawing is 4-400m / min.

[0042] (2) After the optical fiber preform is melted in the graphite furnace and drawn to the target outer diameter, the bare optical fiber is cooled naturally, and then coated with different resin coatings through the coating mold to obtain the optical fiber with the target outer diameter;

[0043] (3) According to product requirements, choose to use a single light curing system or heat curing system, select the light curing system or heat curing system by moving the mounting bracket, or choose a combination of light curing system and he...

Embodiment

[0048] (1) Use a graphite furnace to melt and draw the optical fiber preform, wherein the heating temperature is 1700-2200°C; among them, the optical fiber preform used for drawing can be different types of optical rods, and its outer diameter ranges from φ20-30mm ; The drawing speed is 4-400m / min.

[0049] (2) Naturally cool after melting and drawing, and then enter the first coating mold for a resin coating to obtain an optical fiber. The paint is injected from the tank into the mold by air pressure control. Optical fibers with different coating thicknesses correspond to different coating outlet die sizes to ensure the accuracy of the coating size.

[0050] (3) The optical fiber coated with resin coating is cured by light or heat curing system; the optical fiber is coated with resin for the second time through the second coating mold to obtain the optical fiber, and then cured, repeating the first coating and curing .

[0051] (4) The coating resin adopts polyimide therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com