Full-hydraulic short type cover moving machine

A fully hydraulic, cover-moving technology, applied in the discharge device and other directions, can solve problems such as the inability of the crane to enter, and achieve the effects of ensuring balance and coordination, reducing back pressure and hydraulic shock, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

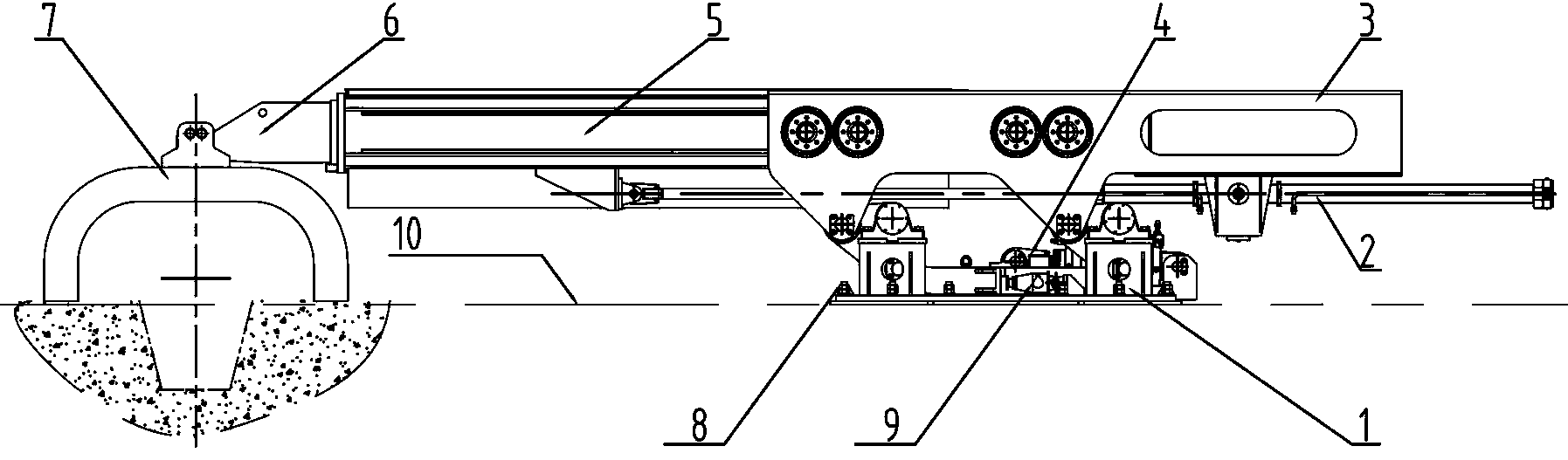

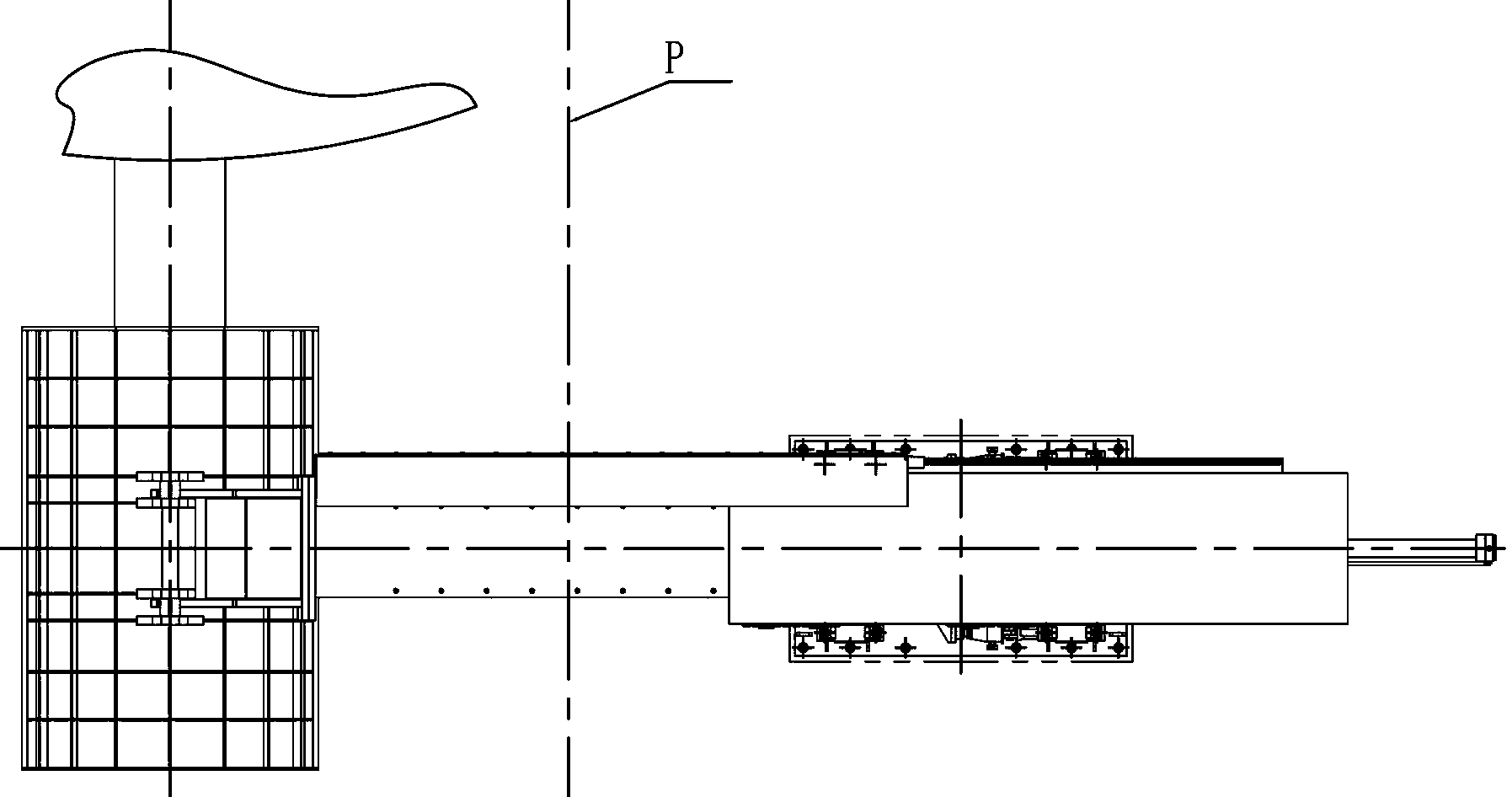

[0018] see Figure 1-2 , a full-hydraulic low-type cover-moving machine, which includes a basic frame 8 fixed on the plane 10 of the blast furnace casthouse. The basic frame 8 is provided with a lifting mechanism 1. The lifting mechanism 1 mainly includes a lifting cylinder 4. The cover machine also includes a walking oil cylinder 2, which is installed on the walking beam 5, drives the walking beam 5 to move on the vehicle frame 3, and is provided with a hook 6 at the front end of the walking beam 5, and the ditch cover 7 is installed on the hook 6.

[0019] The oil inlet of the rodless chamber of the lifting cylinder 4 is equipped with a relief valve and a sequence valve, and the rod chamber is equipped with a relief valve to reduce back pressure and hydraulic shock, and at the same time ensure that the ditch cover stays in any position .

[0020] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com